OPERATION

OPERATION

When attaching the Implement input driveline to the Tractor PTO, it is important that the connecting yoke spring activated locking collar slides freely and the locking balls are seated securely in the groove on the Tractor PTO shaft. Push and pull the driveline back and forth several times to ensure it is securely attached. A driveline not attached correctly to the Tractor PTO shaft could come loose and result in personal injury and damage to the Implement.

7.1 Driveline Length Check

Before operating the Implement, check to make sure the Implement input driveline will not

bottom out or become disengaged. Bottoming out occurs when the inner shaft penetrates the outer housing until the assembly becomes

When fitting the mower to the tractor, the telescoping driveline must be inspected to ensure that at its most compressed position, the profiles do not “bottom out”, and when at its farthest extended position, there is sufficient engagement between the profiles to operate safely. At its shortest length, there must be at least a 1” clearance between each profile end and opposite profile universal joint. At its farthest operating extension, a minimum profile engagement of 6” must be maintained for a Constant Velocity (CV) tube type driveline and a minimum engagement of 6” for

“Bottoming Out” Check Procedure

•Disconnect driveline from the tractor and slide the profiles together until fully compressed.

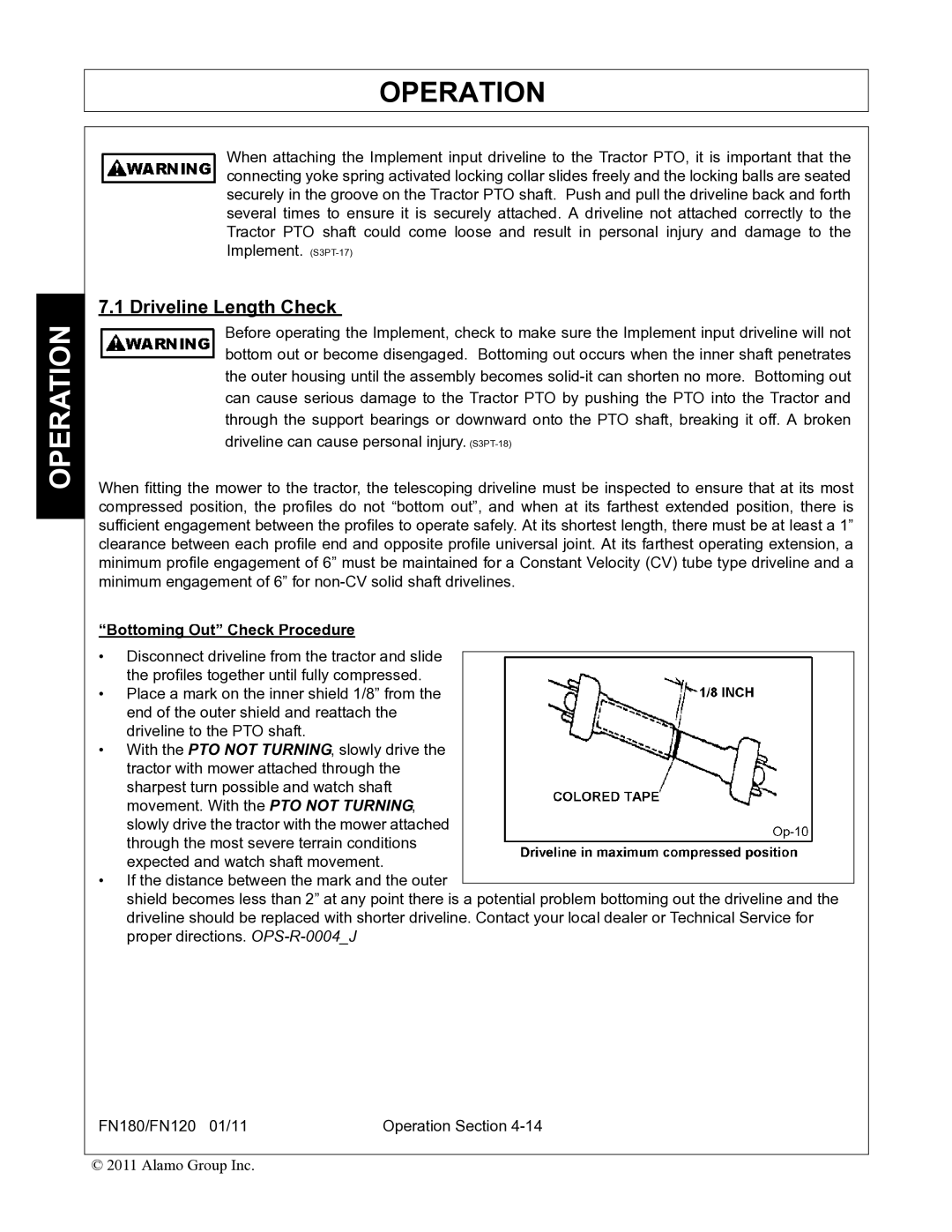

•Place a mark on the inner shield 1/8” from the end of the outer shield and reattach the driveline to the PTO shaft.

•With the PTO NOT TURNING, slowly drive the tractor with mower attached through the sharpest turn possible and watch shaft movement. With the PTO NOT TURNING, slowly drive the tractor with the mower attached through the most severe terrain conditions expected and watch shaft movement.

•If the distance between the mark and the outer

shield becomes less than 2” at any point there is a potential problem bottoming out the driveline and the driveline should be replaced with shorter driveline. Contact your local dealer or Technical Service for proper directions.

FN180/FN120 01/11 | Operation Section |

© 2011 Alamo Group Inc.