OPERATION

OPERATION

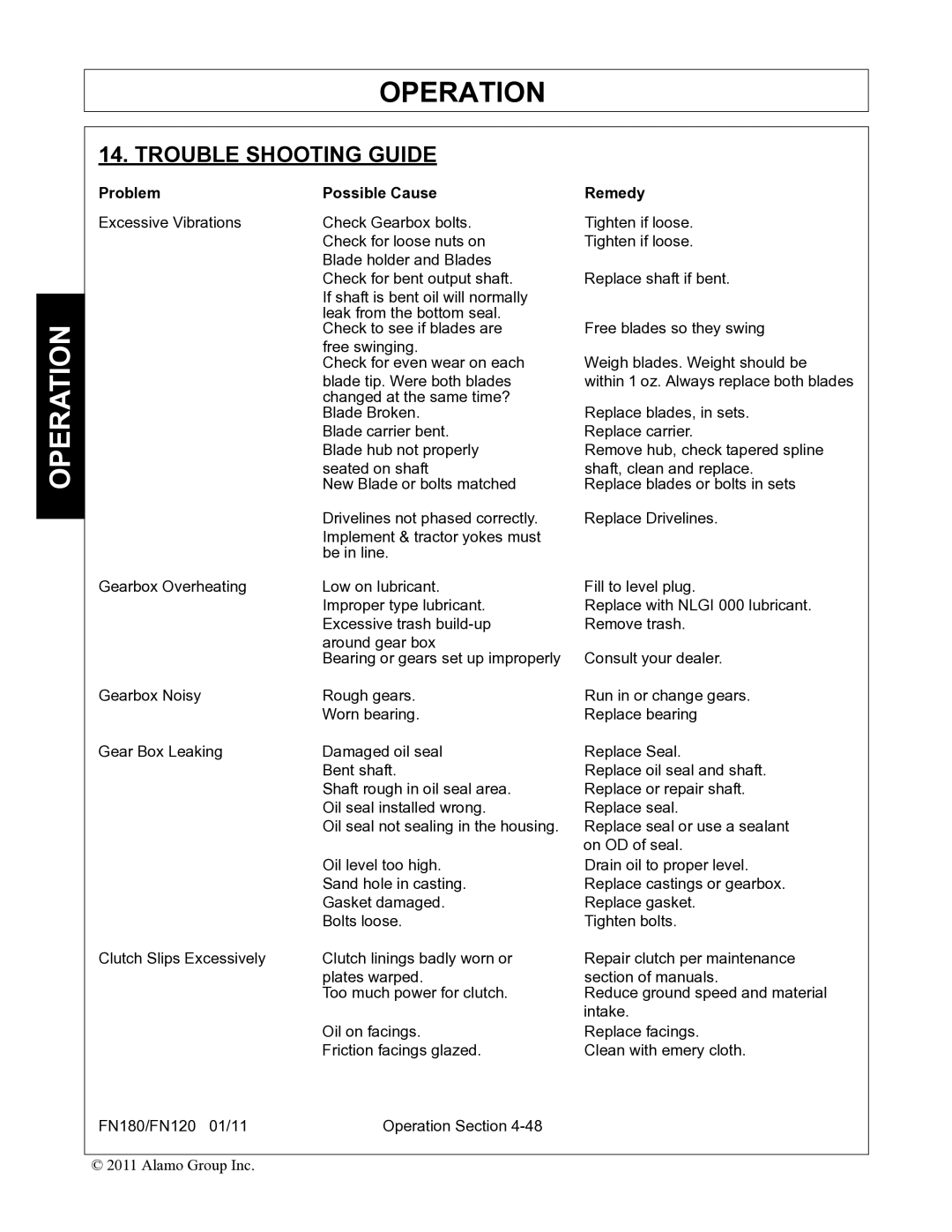

14. TROUBLE SHOOTING GUIDE

Problem | Possible Cause | Remedy |

Excessive Vibrations | Check Gearbox bolts. | Tighten if loose. |

| Check for loose nuts on | Tighten if loose. |

| Blade holder and Blades |

|

| Check for bent output shaft. | Replace shaft if bent. |

| If shaft is bent oil will normally |

|

| leak from the bottom seal. | Free blades so they swing |

| Check to see if blades are | |

| free swinging. | Weigh blades. Weight should be |

| Check for even wear on each | |

| blade tip. Were both blades | within 1 oz. Always replace both blades |

| changed at the same time? | Replace blades, in sets. |

| Blade Broken. | |

| Blade carrier bent. | Replace carrier. |

| Blade hub not properly | Remove hub, check tapered spline |

| seated on shaft | shaft, clean and replace. |

| New Blade or bolts matched | Replace blades or bolts in sets |

| Drivelines not phased correctly. | Replace Drivelines. |

| Implement & tractor yokes must |

|

| be in line. |

|

Gearbox Overheating | Low on lubricant. | Fill to level plug. |

| Improper type lubricant. | Replace with NLGI 000 lubricant. |

| Excessive trash | Remove trash. |

| around gear box | Consult your dealer. |

| Bearing or gears set up improperly | |

Gearbox Noisy | Rough gears. | Run in or change gears. |

| Worn bearing. | Replace bearing |

Gear Box Leaking | Damaged oil seal | Replace Seal. |

| Bent shaft. | Replace oil seal and shaft. |

| Shaft rough in oil seal area. | Replace or repair shaft. |

| Oil seal installed wrong. | Replace seal. |

| Oil seal not sealing in the housing. | Replace seal or use a sealant |

|

| on OD of seal. |

| Oil level too high. | Drain oil to proper level. |

| Sand hole in casting. | Replace castings or gearbox. |

| Gasket damaged. | Replace gasket. |

| Bolts loose. | Tighten bolts. |

Clutch Slips Excessively | Clutch linings badly worn or | Repair clutch per maintenance |

| plates warped. | section of manuals. |

| Too much power for clutch. | Reduce ground speed and material |

|

| intake. |

| Oil on facings. | Replace facings. |

| Friction facings glazed. | Clean with emery cloth. |

FN180/FN120 01/11 | Operation Section |

|

|

|

|

© 2011 Alamo Group Inc. |

|

|