ASSEMBLY

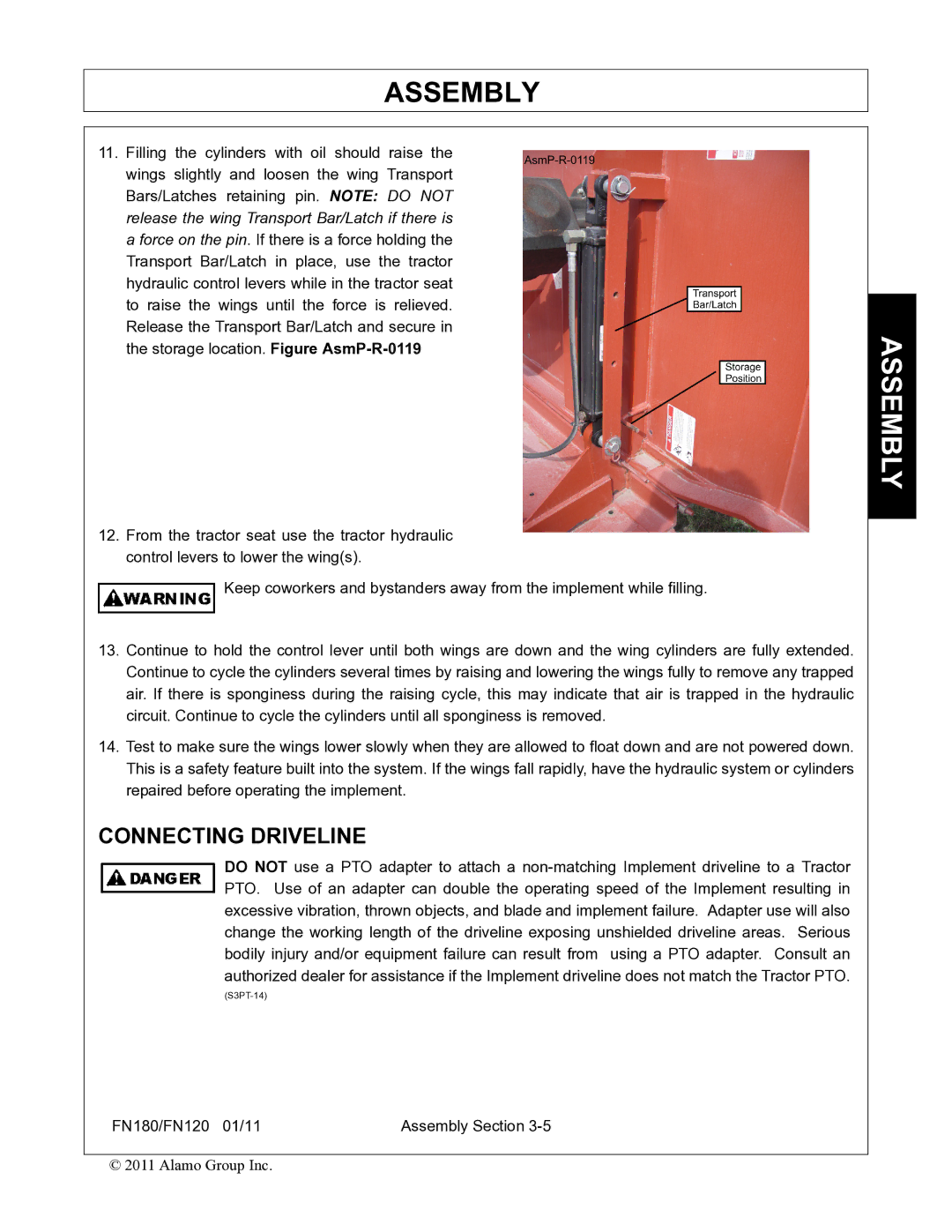

11.Filling the cylinders with oil should raise the wings slightly and loosen the wing Transport Bars/Latches retaining pin. NOTE: DO NOT release the wing Transport Bar/Latch if there is a force on the pin. If there is a force holding the Transport Bar/Latch in place, use the tractor hydraulic control levers while in the tractor seat to raise the wings until the force is relieved. Release the Transport Bar/Latch and secure in the storage location. Figure

12.From the tractor seat use the tractor hydraulic control levers to lower the wing(s).

Keep coworkers and bystanders away from the implement while filling.

13.Continue to hold the control lever until both wings are down and the wing cylinders are fully extended. Continue to cycle the cylinders several times by raising and lowering the wings fully to remove any trapped air. If there is sponginess during the raising cycle, this may indicate that air is trapped in the hydraulic circuit. Continue to cycle the cylinders until all sponginess is removed.

14.Test to make sure the wings lower slowly when they are allowed to float down and are not powered down. This is a safety feature built into the system. If the wings fall rapidly, have the hydraulic system or cylinders repaired before operating the implement.

CONNECTING DRIVELINE

DO NOT use a PTO adapter to attach a

FN180/FN120 01/11 | Assembly Section |

© 2011 Alamo Group Inc.