MAINTENANCE

MAINTENANCE

BLADE SERVICING

Inspect blades before each use to determine that they are properly installed and in good condition. Replace any blade that is bent, excessively nicked, worn, or has any other damage. Small nicks can be ground out when sharpening.

Use only original equipment blades on this cutter. They are made of special

Replace bent or broken blade with new blades. NEVER ATTEMPT TO STRAIGHTEN OR WELD ON BLADES SINCE THIS WILL LIKELY CRACK OR OTHERWISE DAMAGE THE BLADE WITH SUBSEQUENT FAILURE AND POSSIBLE SERIOUS INJURY FROM THROWN BLADES.

•Manually wiggle the glade carriers to check for any looseness.

•Retighten any loose parts.

•Recheck torque every 50 hours.

Operating with loose blade hardware will damage the blade holder and blades. Whenever the blades have been removed or replaced, the hardware must be retightened after the first eight hours of operation. On new units check blade hardware and the blade nut torque after first 8 hours.

Operating with loose blade holder will damage the blade holder and output shaft, two initial tightenings are required. Retighten after one hour and again after the day of operation. In severe cutting conditions or commercial use, a daily inspection is required.

To help prevent structural damage caused by loose hardware, tighten gear case hardware as specified. Check torque after first 8 hours of use and every 50 hours thereafter.

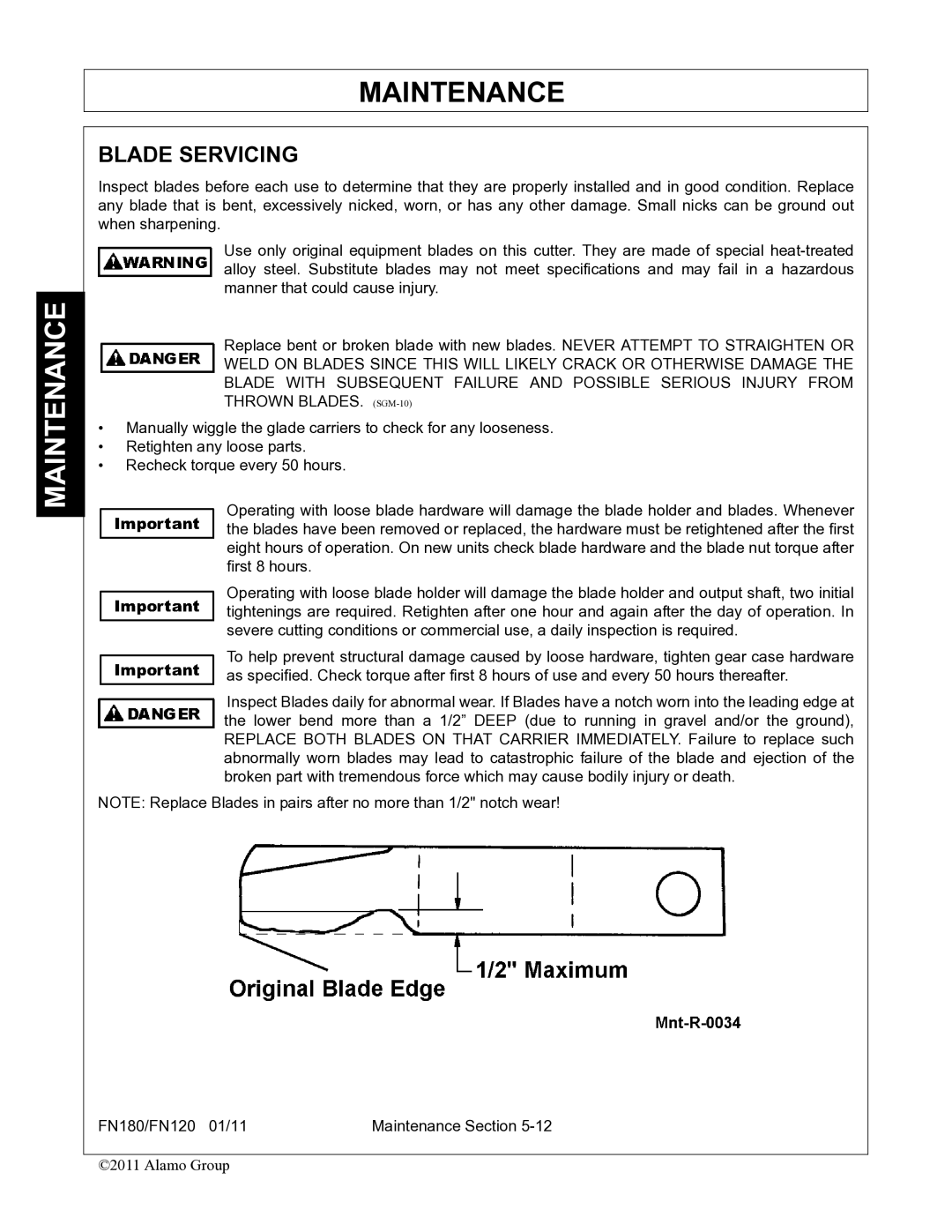

Inspect Blades daily for abnormal wear. If Blades have a notch worn into the leading edge at the lower bend more than a 1/2” DEEP (due to running in gravel and/or the ground), REPLACE BOTH BLADES ON THAT CARRIER IMMEDIATELY. Failure to replace such abnormally worn blades may lead to catastrophic failure of the blade and ejection of the broken part with tremendous force which may cause bodily injury or death.

NOTE: Replace Blades in pairs after no more than 1/2" notch wear!

FN180/FN120 01/11 | Maintenance Section |

©2011 Alamo Group