MAINTENANCE

MAIN & JACKSHAFT DRIVELINE SHIELDS

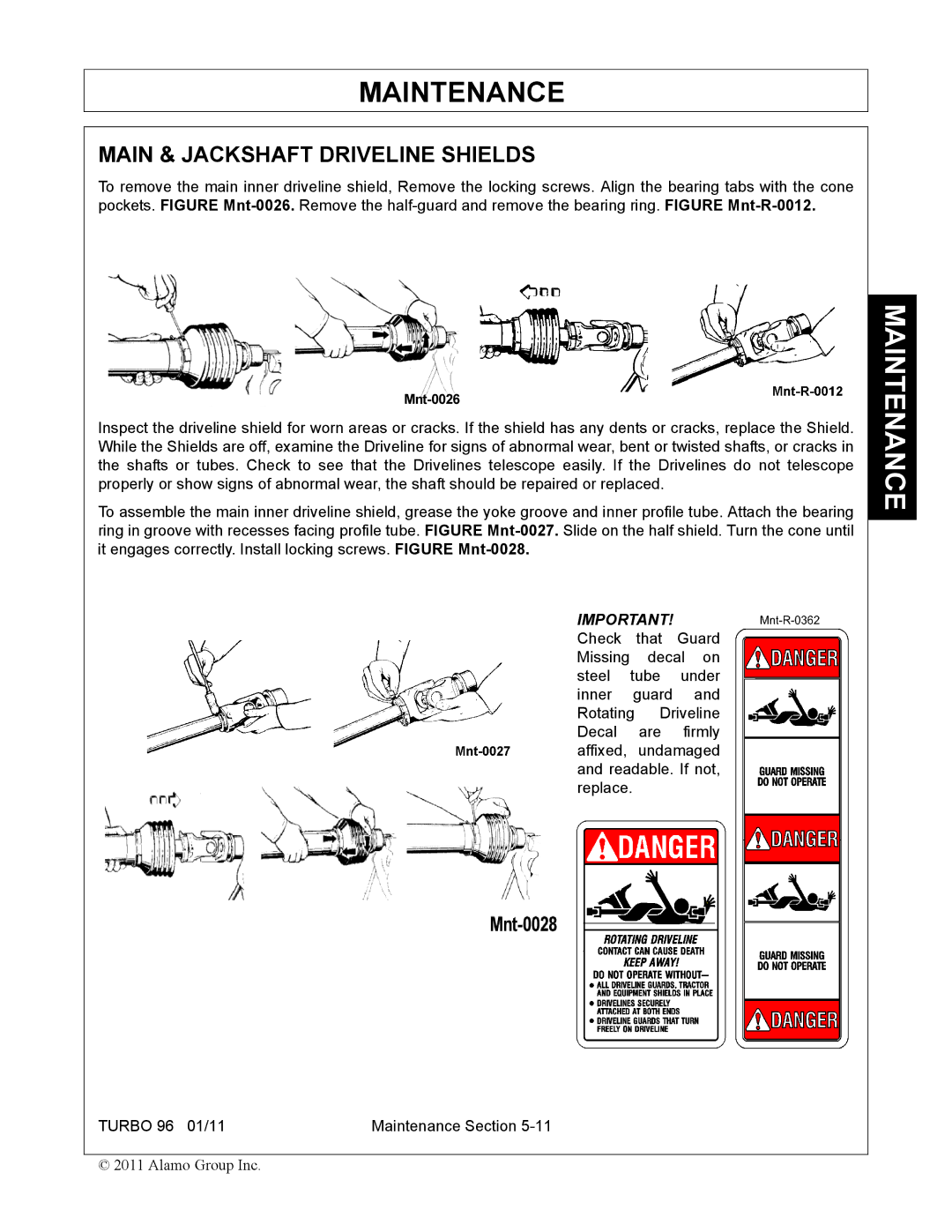

To remove the main inner driveline shield, Remove the locking screws. Align the bearing tabs with the cone pockets. FIGURE

Inspect the driveline shield for worn areas or cracks. If the shield has any dents or cracks, replace the Shield. While the Shields are off, examine the Driveline for signs of abnormal wear, bent or twisted shafts, or cracks in the shafts or tubes. Check to see that the Drivelines telescope easily. If the Drivelines do not telescope properly or show signs of abnormal wear, the shaft should be repaired or replaced.

To assemble the main inner driveline shield, grease the yoke groove and inner profile tube. Attach the bearing ring in groove with recesses facing profile tube. FIGURE

IMPORTANT! Check that Guard Missing decal on steel tube under inner guard and Rotating Driveline Decal are firmly affixed, undamaged and readable. If not, replace.

TURBO 96 01/11 | Maintenance Section |

© 2011 Alamo Group Inc.