OPERATION

OPERATION

Operating the mower with loose blade hardware will damage the blade holder or blades and can result in blade breakage or blade fastener failure. Broken blades or bolts can be thrown out from under the mower for distances up to 300 feet. When the blades are replaced, the fastening hardware must be replaced. Check and retighten the blade hardware after the first eight hours of operation. In severe cutting conditions, recheck the blade carrier and blade bolt torque every 50 hours.

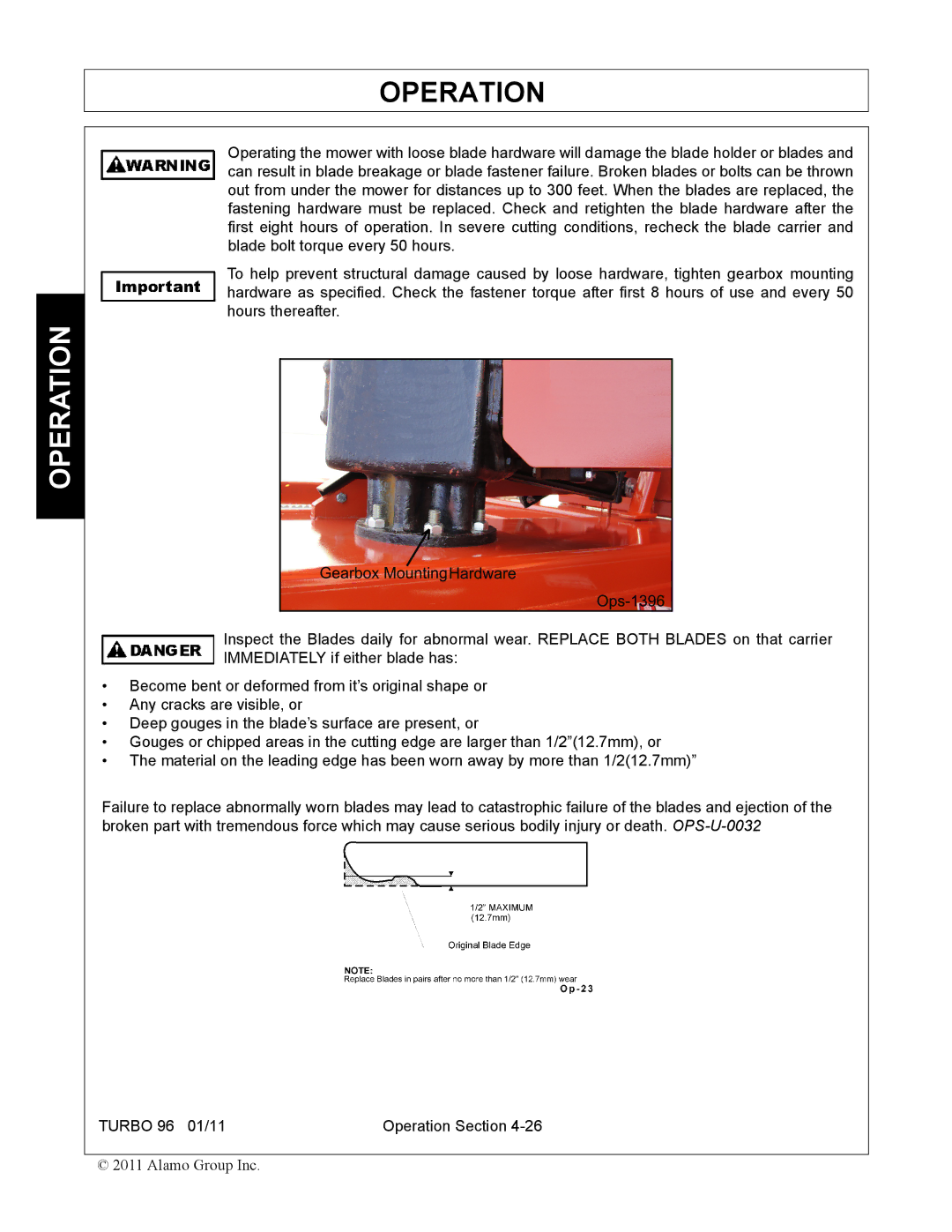

To help prevent structural damage caused by loose hardware, tighten gearbox mounting hardware as specified. Check the fastener torque after first 8 hours of use and every 50 hours thereafter.

Inspect the Blades daily for abnormal wear. REPLACE BOTH BLADES on that carrier IMMEDIATELY if either blade has:

•Become bent or deformed from it’s original shape or

•Any cracks are visible, or

•Deep gouges in the blade’s surface are present, or

•Gouges or chipped areas in the cutting edge are larger than 1/2”(12.7mm), or

•The material on the leading edge has been worn away by more than 1/2(12.7mm)”

Failure to replace abnormally worn blades may lead to catastrophic failure of the blades and ejection of the broken part with tremendous force which may cause serious bodily injury or death.

TURBO 96 01/11 | Operation Section |

© 2011 Alamo Group Inc.