MAINTENANCE

MAINTENANCE

SLIP CLUTCH

A slip clutch is incorporated in the PTO driveline. It is designed to slip, absorb the shock load, and protect the driveline.

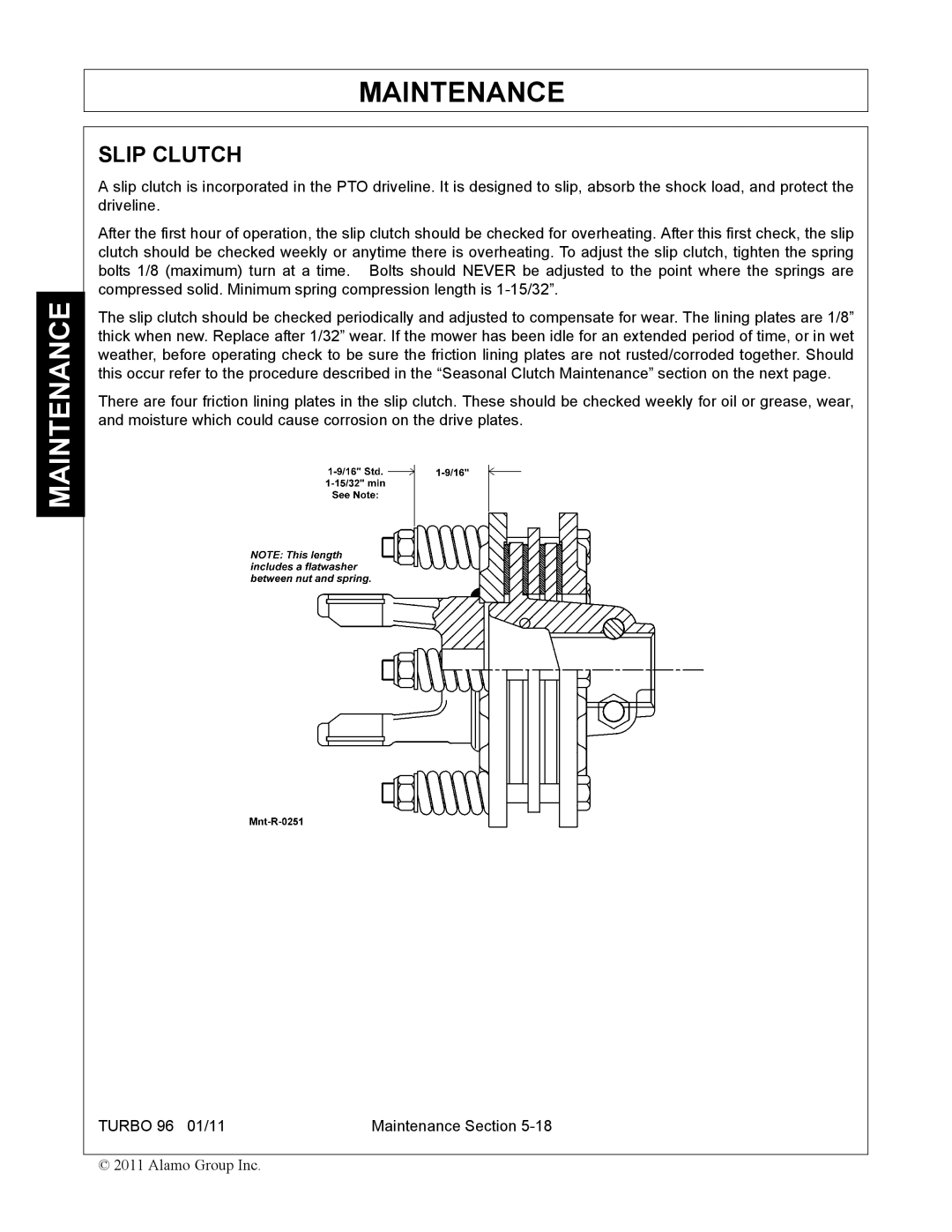

After the first hour of operation, the slip clutch should be checked for overheating. After this first check, the slip clutch should be checked weekly or anytime there is overheating. To adjust the slip clutch, tighten the spring bolts 1/8 (maximum) turn at a time. Bolts should NEVER be adjusted to the point where the springs are compressed solid. Minimum spring compression length is

The slip clutch should be checked periodically and adjusted to compensate for wear. The lining plates are 1/8” thick when new. Replace after 1/32” wear. If the mower has been idle for an extended period of time, or in wet weather, before operating check to be sure the friction lining plates are not rusted/corroded together. Should this occur refer to the procedure described in the “Seasonal Clutch Maintenance” section on the next page.

There are four friction lining plates in the slip clutch. These should be checked weekly for oil or grease, wear, and moisture which could cause corrosion on the drive plates.

TURBO 96 01/11 | Maintenance Section |

© 2011 Alamo Group Inc.