MAINTENANCE

BLADE TIMING AND ROTATION

Blades on

BLADE TIMING PROCEDURE

1.Raise the mower to minimum height to allow sufficient clearance between the mower deck and ground to visually inspect blade carriers.

2.Completely shut down the tractor and secure the tractor in position by placing the tractor in park and setting the parking brake. Securely block the mower at this height.

3.On a side gearbox, remove connecting coupler.

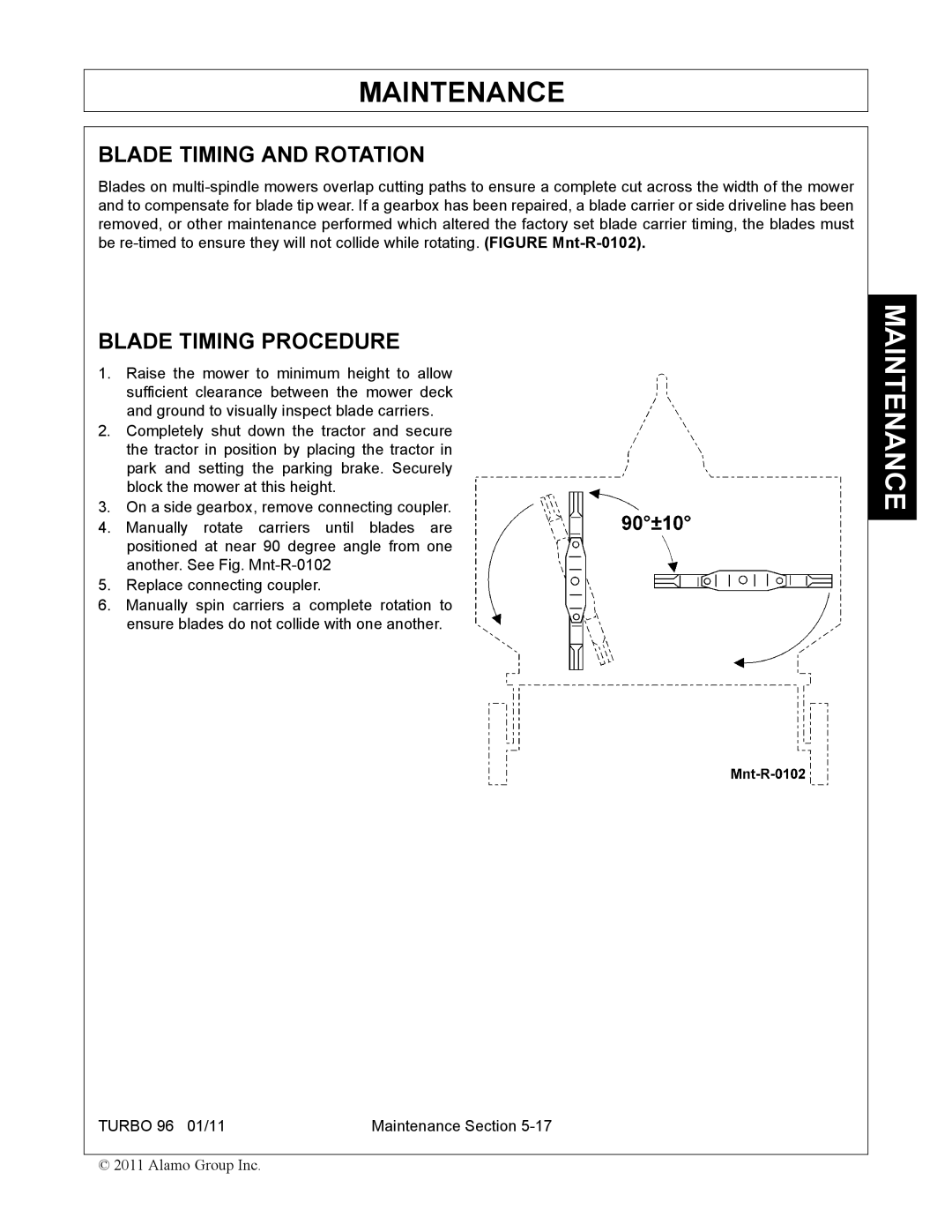

4.Manually rotate carriers until blades are positioned at near 90 degree angle from one another. See Fig.

5.Replace connecting coupler.

6.Manually spin carriers a complete rotation to ensure blades do not collide with one another.

TURBO 96 01/11 | Maintenance Section |

© 2011 Alamo Group Inc.