ASSEMBLY

nReplace throat plate and table pin.

nTransportation and handling may have caused some fasteners to loosen. Before operating, check all screws, bolts and nuts to make sure they are snug. Operate machine only after reading the entire operator's manual including blade tracking, blade guide adjustments, and safety rules.

ADJUSTING BLADE TENSION

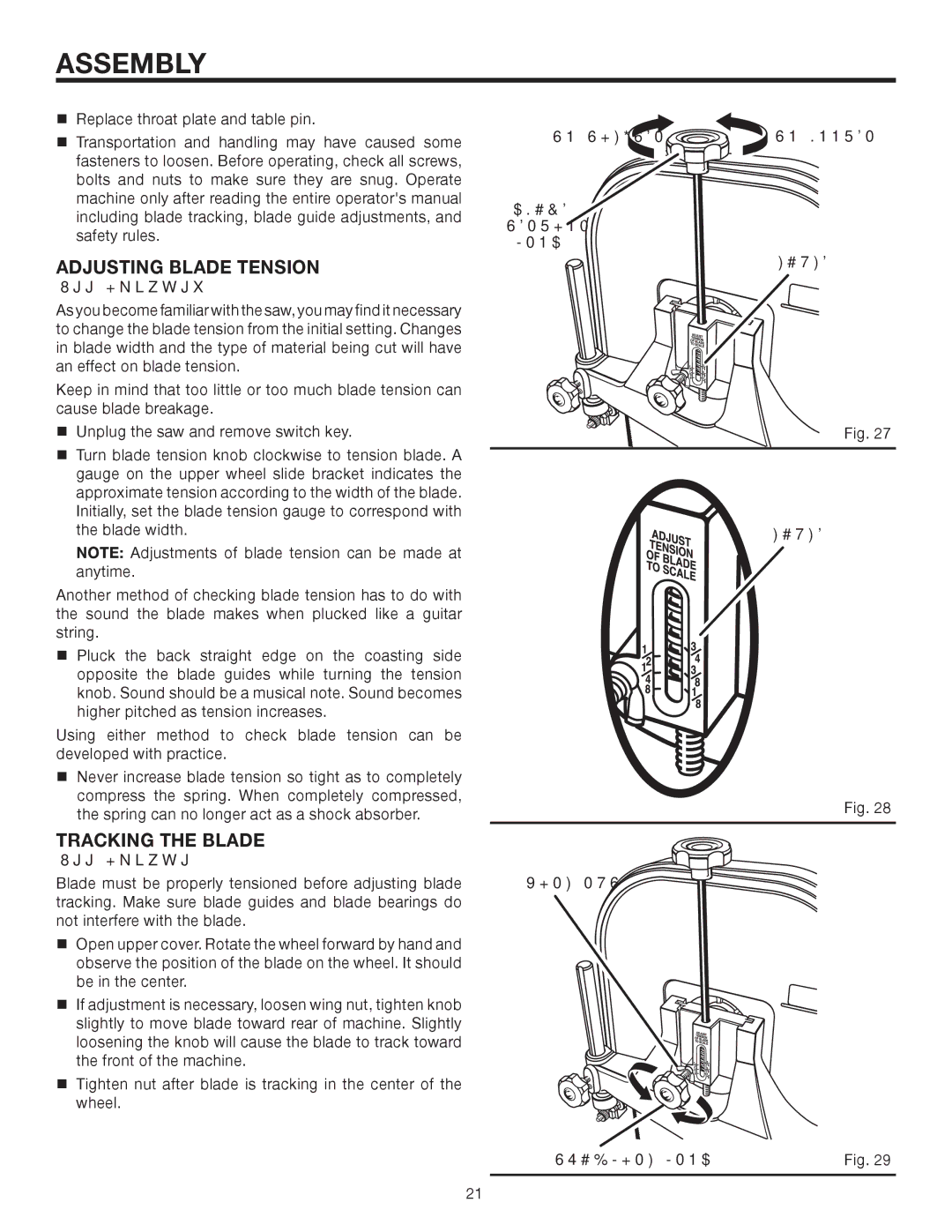

See Figures 27 - 28.

As you become familiar with the saw, you may find it necessary to change the blade tension from the initial setting. Changes in blade width and the type of material being cut will have an effect on blade tension.

Keep in mind that too little or too much blade tension can cause blade breakage.

nUnplug the saw and remove switch key.

nTurn blade tension knob clockwise to tension blade. A gauge on the upper wheel slide bracket indicates the approximate tension according to the width of the blade. Initially, set the blade tension gauge to correspond with the blade width.

NOTE: Adjustments of blade tension can be made at anytime.

Another method of checking blade tension has to do with the sound the blade makes when plucked like a guitar string.

n Pluck the back straight edge on the coasting side opposite the blade guides while turning the tension knob. Sound should be a musical note. Sound becomes higher pitched as tension increases.

Using either method to check blade tension can be developed with practice.

nNever increase blade tension so tight as to completely compress the spring. When completely compressed, the spring can no longer act as a shock absorber.

TRACKING THE BLADE

See Figure 29.

Blade must be properly tensioned before adjusting blade tracking. Make sure blade guides and blade bearings do not interfere with the blade.

nOpen upper cover. Rotate the wheel forward by hand and observe the position of the blade on the wheel. It should be in the center.

nIf adjustment is necessary, loosen wing nut, tighten knob slightly to move blade toward rear of machine. Slightly loosening the knob will cause the blade to track toward the front of the machine.

nTighten nut after blade is tracking in the center of the wheel.

TO TIGHTEN ![]()

![]()

![]() TO LOOSEN

TO LOOSEN

BLADE

TENSION

KNOB

GAUGE

Fig. 27

GAUGE

Fig. 28

WING NUT

TRACKING KNOB | Fig. 29 |

|

|

21