Adjusting Table Gibs

“Gibs” are provided to take up all play between the mat- ing dovetail ways of the base and infeed and outfeed tables of your jointer. Proper gib adjustment is necessary for the correct functioning of the jointer. The gibs on your machine were adjusted at the factory and should require no further adjustment. However, to adjust the gibs pro- ceed as follows:

1.Loosen each of the lock nuts. Make sure the table locks are also loose.

2.Finger tighten each set screw in turn, until the screw “bottoms out”. Do not overtighten the screws.

3.Recheck table play. If table is still loose, repeat step 2. If table is snug, tighten the set screw lock nuts without allowing set screws to turn.

4.Check that the table raises and lowers freely with the elevation handwheel. If there is too much resistance, loosen the set screws and repeat adjustment.

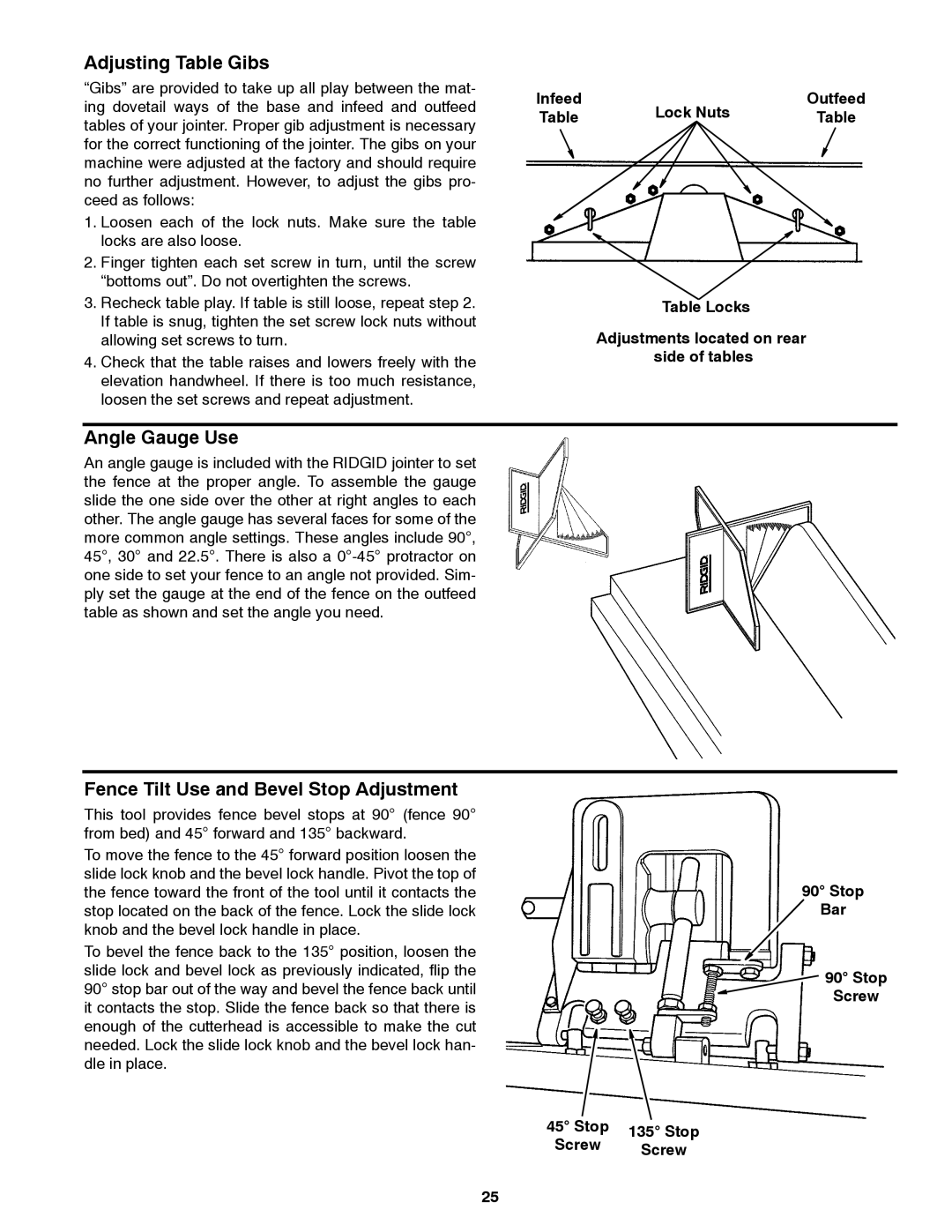

Infeed | Lock Nuts | Outfeed | |

Table | Table | ||

|

Table Locks

Adjustments located on rear side of tables

Angle Gauge Use

An angle gauge is included with the RIDGID jointer to set the fence at the proper angle. To assemble the gauge slide the one side over the other at right angles to each other. The angle gauge has several faces for some of the more common angle settings. These angles include 90°, 45°, 30° and 22.5°. There is also a

Fence Tilt Use and Bevel Stop Adjustment

This tool provides fence bevel stops at 90° (fence 90° from bed) and 45° forward and 135° backward.

To move the fence to the 45° forward position loosen the slide lock knob and the bevel lock handle. Pivot the top of the fence toward the front of the tool until it contacts the stop located on the back of the fence. Lock the slide lock knob and the bevel lock handle in place.

To bevel the fence back to the 135° position, loosen the slide lock and bevel lock as previously indicated, flip the 90° stop bar out of the way and bevel the fence back until it contacts the stop. Slide the fence back so that there is enough of the cutterhead is accessible to make the cut needed. Lock the slide lock knob and the bevel lock han- dle in place.

45° Stop

Screw

135° Stop

Screw

90° Stop

Bar

![]() 90° Stop

90° Stop

Screw

25