Basic Jointer/Planer Cutting Operations (continued)

Planing

![]() WARNING: To avoid risk or injury from cutterhead contact, always use push blocks when planing.

WARNING: To avoid risk or injury from cutterhead contact, always use push blocks when planing.

•Follow all instructions above for “Feeding the Work- piece”.

•Keep fingers close together so they do not hang down toward the knives.

Planing is removing wood from the widest surface or face of a board so as to make it flat and smooth.

Planing on a jointer will not necessarily make the face that is planed square or parallel to any other surface. Planing on a jointer only smooths and flattens. If you are planing and jointing a board, the planing operation should be performed first. This allows the jointed edge to be cut square to the face which was previously planed flat and smooth.

Jointing

Jointing is the removal of wood along the edge of a piece of wood so as to make that edge straight, smooth and square to the wood face which is against the fence.

To ensure a square cut, the workpiece face must be held flat against the fence throughout the entire cut.

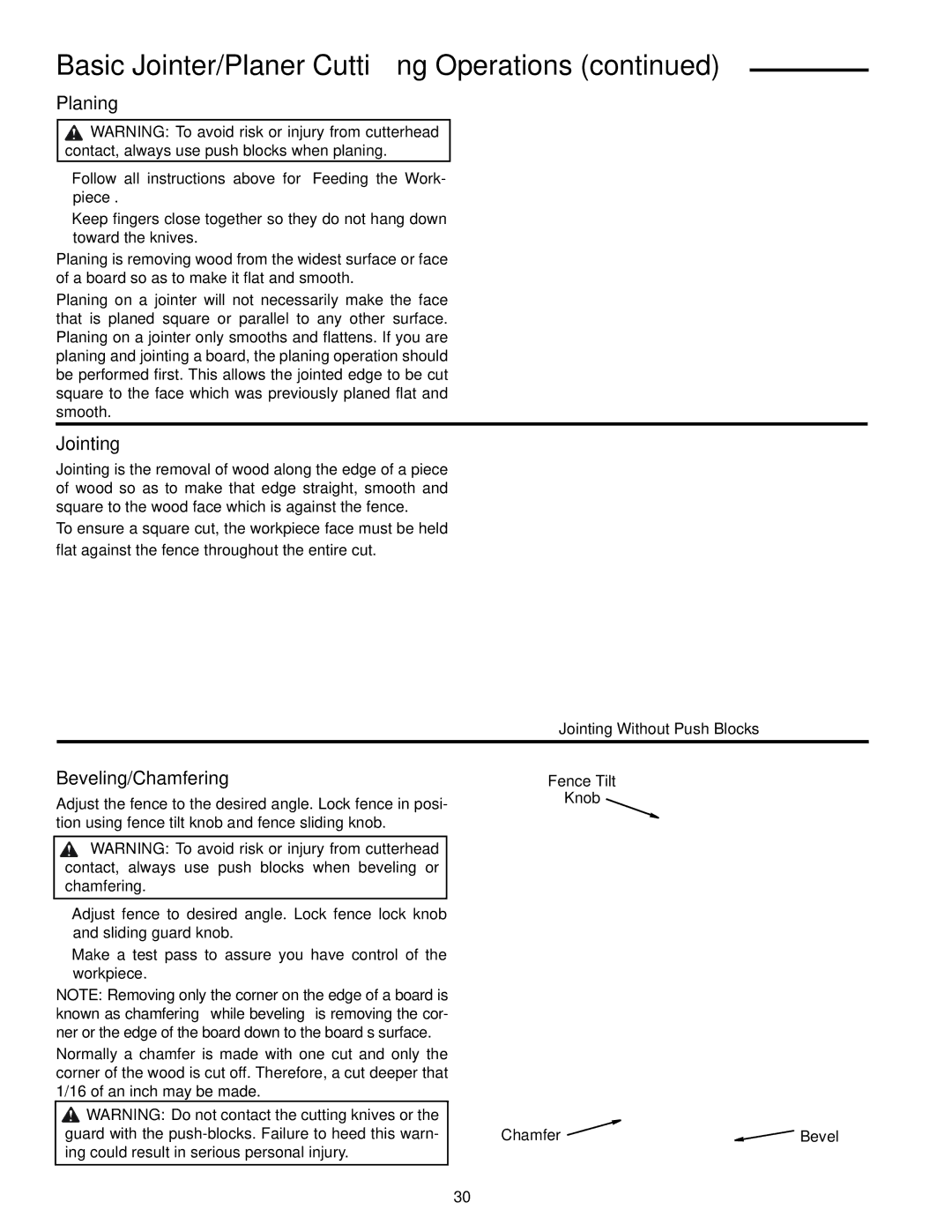

Jointing Without Push Blocks

Beveling/Chamfering

Adjust the fence to the desired angle. Lock fence in posi- tion using fence tilt knob and fence sliding knob.

![]() WARNING: To avoid risk or injury from cutterhead contact, always use push blocks when beveling or chamfering.

WARNING: To avoid risk or injury from cutterhead contact, always use push blocks when beveling or chamfering.

•Adjust fence to desired angle. Lock fence lock knob and sliding guard knob.

•Make a test pass to assure you have control of the workpiece.

NOTE: Removing only the corner on the edge of a board is known as chamfering while beveling is removing the cor- ner or the edge of the board down to the board’s surface.

Normally a chamfer is made with one cut and only the corner of the wood is cut off. Therefore, a cut deeper that 1/16 of an inch may be made.

![]() WARNING: Do not contact the cutting knives or the guard with the

WARNING: Do not contact the cutting knives or the guard with the

Fence Tilt

Knob

Chamfer | Bevel |

30