ASSEMBLY

ADJUSTING THE BEVEL LOCK LEVER

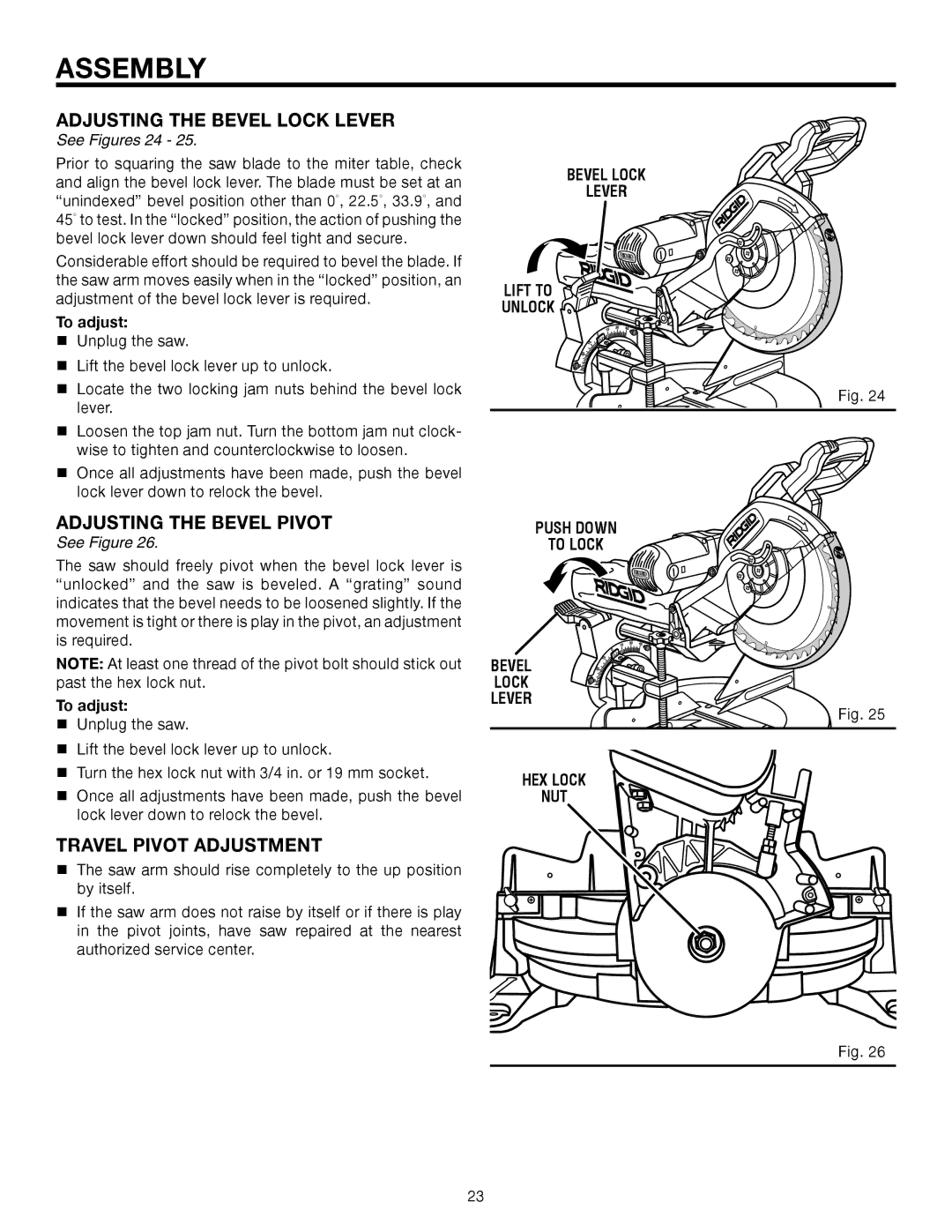

See Figures 24 - 25.

Prior to squaring the saw blade to the miter table, check and align the bevel lock lever. The blade must be set at an “unindexed” bevel position other than 0°, 22.5°, 33.9°, and 45° to test. In the “locked” position, the action of pushing the bevel lock lever down should feel tight and secure.

Considerable effort should be required to bevel the blade. If the saw arm moves easily when in the “locked” position, an adjustment of the bevel lock lever is required.

To adjust:

Unplug the saw.

Lift the bevel lock lever up to unlock.

Locate the two locking jam nuts behind the bevel lock lever.

Loosen the top jam nut. Turn the bottom jam nut clock- wise to tighten and counterclockwise to loosen.

Once all adjustments have been made, push the bevel lock lever down to relock the bevel.

ADJUSTING THE BEVEL PIVOT

See Figure 26.

The saw should freely pivot when the bevel lock lever is “unlocked” and the saw is beveled. A “grating” sound indicates that the bevel needs to be loosened slightly. If the movement is tight or there is play in the pivot, an adjustment is required.

NOTE: At least one thread of the pivot bolt should stick out past the hex lock nut.

To adjust:

Unplug the saw.

Lift the bevel lock lever up to unlock.

Turn the hex lock nut with 3/4 in. or 19 mm socket.

Once all adjustments have been made, push the bevel lock lever down to relock the bevel.

TRAVEL PIVOT ADJUSTMENT

The saw arm should rise completely to the up position by itself.

If the saw arm does not raise by itself or if there is play in the pivot joints, have saw repaired at the nearest authorized service center.

BEVEL LOCK

LEVER

®

LIFT TO

UNLOCK

Fig. 24

PUSH DOWN | ® |

| |

TO LOCK |

|

BEVEL

LOCK

LEVER

Fig. 25

HEX LOCK

NUT

Fig. 26

23