OPERATION

Bevel |

|

|

Angle |

| Type of Cut |

Setting |

|

|

|

| |

| Left side, inside corner | |

0° | 1. | Top edge of molding against fence |

2. Miter table set right 45° | ||

| 3. | Save left end of cut |

|

| |

| Right side, inside corner | |

0° | 1. | Bottom edge of molding against fence |

2. Miter table set left 45° | ||

| 3. | Save left end of cut |

|

| |

| Left side, outside corner | |

0° | 1. | Bottom edge of molding against fence |

2. Miter table set left 45° | ||

| 3. | Save right end of cut |

|

| |

| Right side, outside corner | |

0° | 1. | Top edge of molding against fence |

2. Miter table set right 45° | ||

| 3. | Save right end of cut |

|

|

|

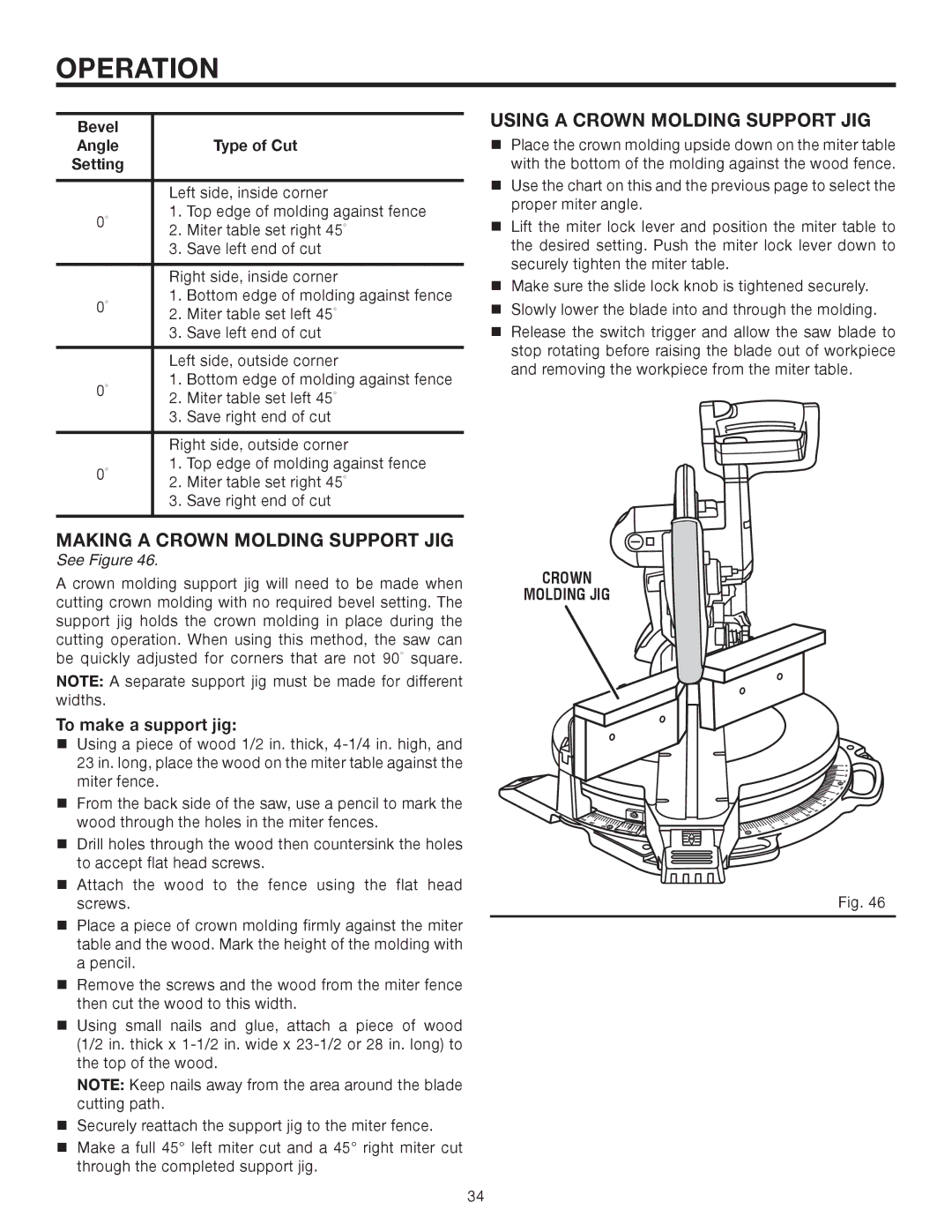

MAKING A CROWN MOLDING SUPPORT JIG

See Figure 46.

A crown molding support jig will need to be made when cutting crown molding with no required bevel setting. The support jig holds the crown molding in place during the cutting operation. When using this method, the saw can be quickly adjusted for corners that are not 90° square.

NOTE: A separate support jig must be made for different widths.

To make a support jig:

Using a piece of wood 1/2 in. thick,

From the back side of the saw, use a pencil to mark the wood through the holes in the miter fences.

Drill holes through the wood then countersink the holes to accept flat head screws.

Attach the wood to the fence using the flat head screws.

Place a piece of crown molding firmly against the miter table and the wood. Mark the height of the molding with a pencil.

Remove the screws and the wood from the miter fence then cut the wood to this width.

Using small nails and glue, attach a piece of wood (1/2 in. thick x

NOTE: Keep nails away from the area around the blade cutting path.

Securely reattach the support jig to the miter fence.

Make a full 45° left miter cut and a 45° right miter cut through the completed support jig.

USING A CROWN MOLDING SUPPORT JIG

Place the crown molding upside down on the miter table with the bottom of the molding against the wood fence.

Use the chart on this and the previous page to select the proper miter angle.

Lift the miter lock lever and position the miter table to the desired setting. Push the miter lock lever down to securely tighten the miter table.

Make sure the slide lock knob is tightened securely.

Slowly lower the blade into and through the molding.

Release the switch trigger and allow the saw blade to stop rotating before raising the blade out of workpiece and removing the workpiece from the miter table.

CROWN

MOLDING JIG

Fig. 46

34