OPERATION

CUTTING WARPED MATERIAL

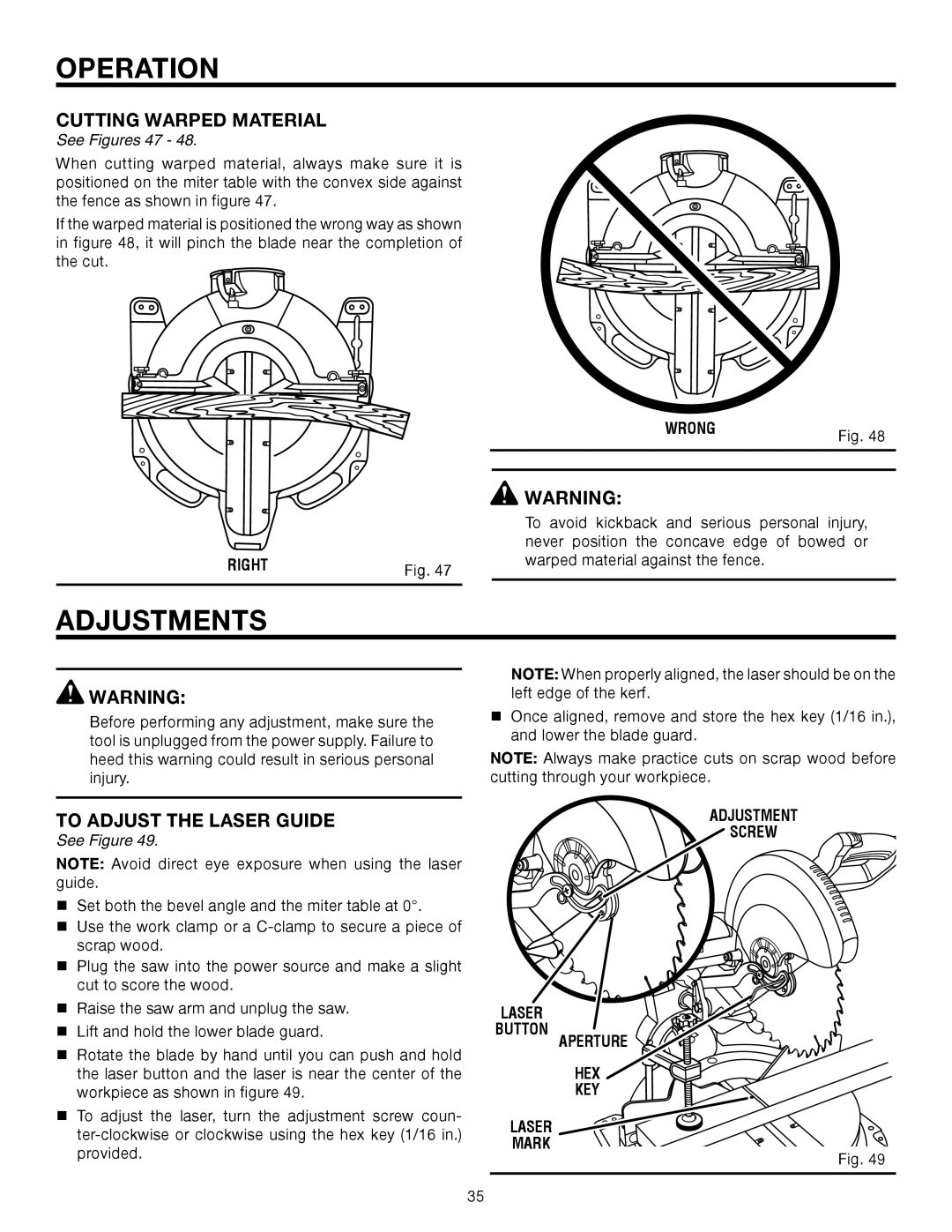

See Figures 47 - 48.

When cutting warped material, always make sure it is positioned on the miter table with the convex side against the fence as shown in figure 47.

If the warped material is positioned the wrong way as shown in figure 48, it will pinch the blade near the completion of the cut.

RIGHT | Fig. 47 |

|

WRONG | Fig. 48 |

|

![]() WARNING:

WARNING:

To avoid kickback and serious personal injury, never position the concave edge of bowed or warped material against the fence.

ADJUSTMENTS

![]() WARNING:

WARNING:

Before performing any adjustment, make sure the tool is unplugged from the power supply. Failure to heed this warning could result in serious personal injury.

TO ADJUST THE LASER GUIDE

See Figure 49.

NOTE: Avoid direct eye exposure when using the laser guide.

Set both the bevel angle and the miter table at 0°.

Use the work clamp or a

Plug the saw into the power source and make a slight cut to score the wood.

Raise the saw arm and unplug the saw.

Lift and hold the lower blade guard.

Rotate the blade by hand until you can push and hold the laser button and the laser is near the center of the workpiece as shown in figure 49.

To adjust the laser, turn the adjustment screw coun-

NOTE: When properly aligned, the laser should be on the left edge of the kerf.

Once aligned, remove and store the hex key (1/16 in.), and lower the blade guard.

NOTE: Always make practice cuts on scrap wood before cutting through your workpiece.

ADJUSTMENT

SCREW

LASER

BUTTON APERTURE

HEX

KEY

LASER

MARK

Fig. 49

35