MAINTENANCE

GENERAL MAINTENANCE

![]() WARNING:

WARNING:

Always begin by disconnecting the power supply.

■Periodically check all clamps, nuts, bolts, screws, and belts for tightness and condition. Make sure the throat plate is in good condition and in position.

■Check the blade guard assembly.

■To maintain the table surfaces, fence, and rails, periodically apply paste wax to them and buff to provide smooth functioning. To prevent work from slipping during cutting operation, DO NOT wax the working face of the miter fence.

■Protect the blade by cleaning out sawdust from underneath the table and in the blade teeth. Use a resin solvent on the blade teeth.

■Clean plastic parts only with a soft damp cloth. DO NOT use any aerosol or petroleum solvents.

LUBRICATION

This saw has been lubricated at the factory prior to shipment. Following extended use, you should inspect and lubricate the following areas to assure smooth operation.

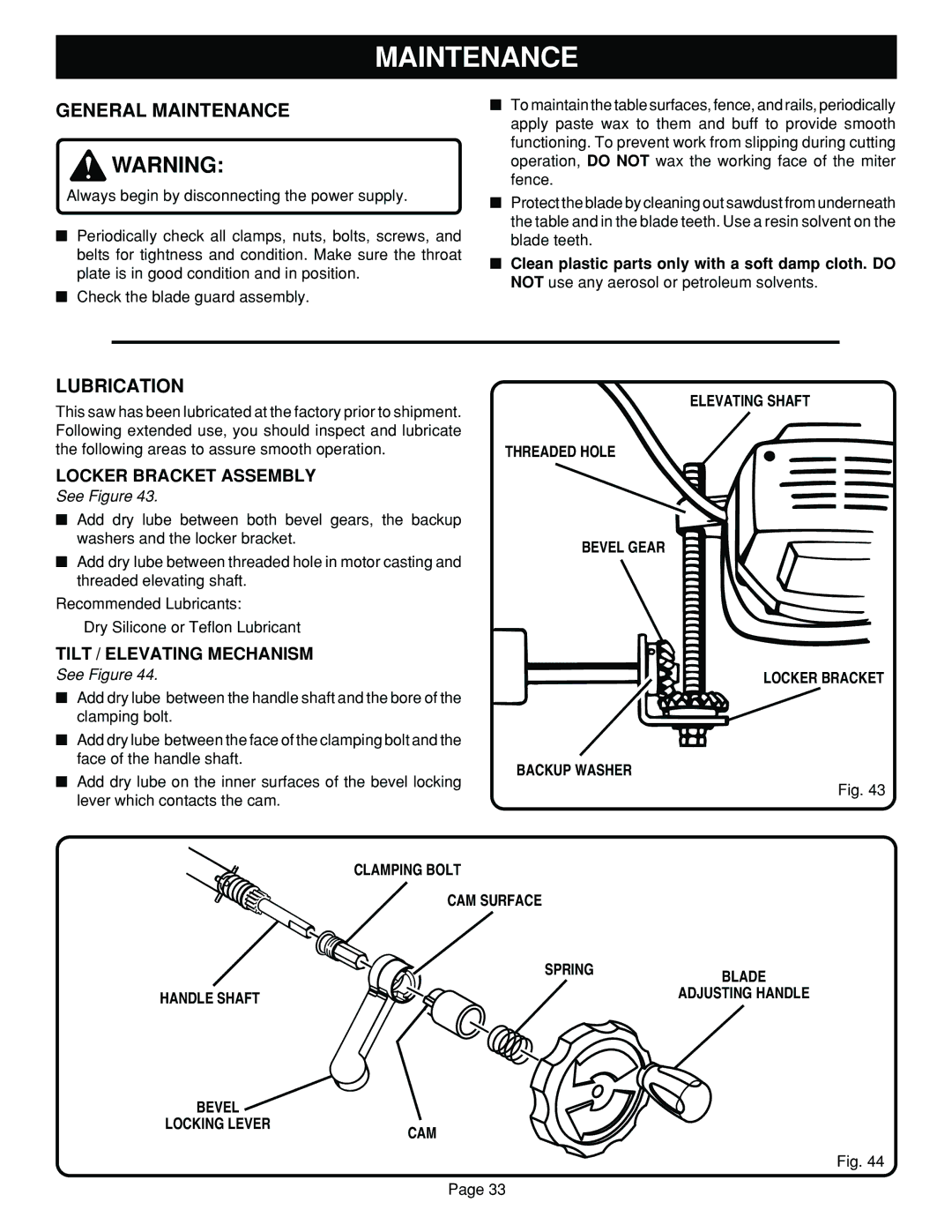

LOCKER BRACKET ASSEMBLY

See Figure 43.

■Add dry lube between both bevel gears, the backup washers and the locker bracket.

■Add dry lube between threaded hole in motor casting and threaded elevating shaft.

Recommended Lubricants:

Dry Silicone or Teflon Lubricant

ELEVATING SHAFT

THREADED HOLE

BEVEL GEAR

TILT / ELEVATING MECHANISM

See Figure 44.

■Add dry lube between the handle shaft and the bore of the clamping bolt.

■Add dry lube between the face of the clamping bolt and the face of the handle shaft.

BACKUP WASHER

■ Add dry lube on the inner surfaces of the bevel locking lever which contacts the cam.

CLAMPING BOLT

LOCKER BRACKET

Fig. 43

HANDLE SHAFT

BEVEL

LOCKING LEVER

CAM SURFACE

SPRING

CAM

Page 33

BLADE

ADJUSTING HANDLE

Fig. 44