PLC-XU46

PLC-XU46 PLC-XU45

Contents

Safety Instructions

Do not Attempt to Servicing Remote Control Unit

Specifications

Adjustments after Parts Replacement

Optical Adjustments Electrical Adjustments

Circuit Protections

Type T4.0AH 250V Fuse Little Fuse INC. Type

Possible causes

Recommendation

Main Board removal

Mechanical Disassemblies

Cabinet Top and Control Panel removal

Temp board

AV, DVI, Temp Board and Speaker removal

Front Panel and R/C Board removal

DVI board

Isolation sheet Lamp ballast board SW902

Lamp Ballast Unit removal

Filter Board removal

Filter board

Power Box Cover and FansFN901, FN906 removal

Optical Unit removal

Power and P.F. Board removal

⁄0Fan FN905 removal

⁄1Fans FN902, FN903, FN904 removal

Projection Lens removal

Integrator Lens-In disassembly

Optical Parts Disassemblies

Condenser lens disassembly

Condenser Lens-Out disassembly

Holder

Relay Lens-Out disassembly

Polarized Glass-In removal

LCD Panel

Polarized Glass-Out/Pre-Polarized Glass removal

Optical Unit Top removal

Prism Ass’y

Locations and Directions

Key No. Description

Color Shading Correction

LCD Panel/Prism Ass’y Replacement

LCD Panel/Prism Ass’y removal

How to check Lamp Replace Counter

Lamp Replacement

How to reset Lamp Replace Counter

B-CONTRAST Adjustment

Optical Adjustments

Contrast adjustment

Condenser Lens adjustment

Green b Slot B Moving of slot B Slot D Moving of Slot D

Condenser Lens-Out adjustment

Cyan a Slot B Moving of slot B Moving of slot D

Slot D Moving of slot D

Relay lens-Out adjustment

White a Slot B a Moving of slot B

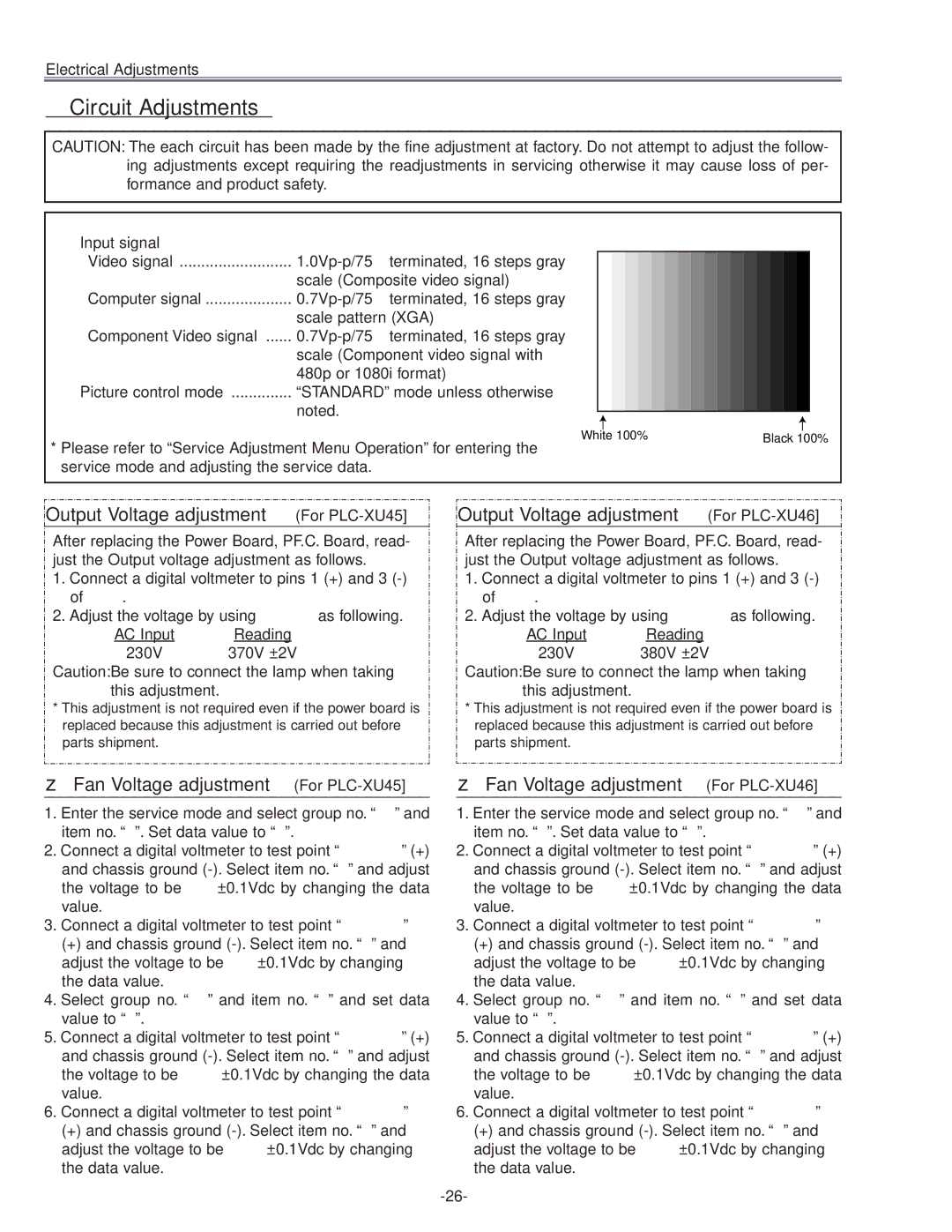

Electrical Adjustments

IC1801 is not defective

Fan Voltage adjustment For PLC-XU45

Output Voltage adjustment For PLC-XU45

Output Voltage adjustment For PLC-XU46

Fan Voltage adjustment For PLC-XU46

V12 Signal Center adjustment

X12 Pedestal adjustment

C12 NRS adjustment

Black Level adjustment

AV Gain adjustment

PC Offset adjustment

M12 PC Gain adjustment

Common Center adjustment

Adjustment

⁄01 Gamma Shift adjustment

⁄11 White Balance adjustment

TB1274

CXA2101

TA1318

LP05 Turbo

Group 500 ADC

Group 10 Option

Fan Control

Group 510 Ntsc Gakaku

Group 515 Hdtv 720p Gakaku

Group 513 Hdtv 1080i-50 Gakaku

Group 514 Hdtv 1035i Gakaku

Group 516 Hdtv 575p Gakaku

Test Points and Locations

Main Board

Troubleshooting

Abnormality occurs on the power circuit

IC801

F601

Fuse Thermal sw. Interlock sw

No picture from both of Video and Computer sources

No picture from Video source

No picture from DVI source

No picture from all of sources

Video Signal processing diagrams

No audio output signal at speaker

No audio signals at AV input circuit

Incorrect operation of VIDEO/COMPUTER mode switching

No power supply at audio circuit

Control Port Functions

System Control & I/O Port Table IC801

Control Port Functions

IIC Bus DA Converter IC1831 Port Functions

IIC Bus I/O Expander IC1851 Port Functions

IIC Bus I/O Expander IC2181 Port Functions

IIC Bus DA Converter IC2571 Port Functions

IIC Bus DA Converter IC2161 Port Functions

IIC Bus DA Converter IC1581 Port Functions

Drive TP52R/TP201R Drive TP52G/TP201G Drive TP52B/TP201G

Waveform

VIDEO-IN

Sync Drive TP62H Sync Drive TP62V DHS Tpdhs DVS Tpdvs

Sync OUT IC4101-29 Sync OUT IC4101-28

Sync in TP205

Ballast SW TP28L

Cleaning

Cleaning with air spray

IC Block Diagrams

BA7078AF Selector, IC6241 CXA2101AQ RGB Matrix, IC4101

IC Block Diagrams

L3E07050 Color, Gamma Correction & Timing Controller , IC401

ML60851 USB I/F, IC9801 M62393 D/A, IC2571

TB1274AF Video Decoder, IC1101 TA1318N AFC Detector, IC6171

IC Block Diagrams

Page

Electrical Parts List

Read Description in the parts list

OUT of Circuit Board

610 292 5609 ASSY,PWB,KEY SW MS6A

Assemblied Boards ME3-XU4500, PLC-XU45

KEY SW Board

Assemblied Boards MF3-XU4600, PLC-XU46

Transistor

AV Board

610 299 7330 ASSY,PWB,AV MK8A

Integrated Circuit

NP-ELECT

Coil

DVI Board

610 299 7347 ASSY,PWB,DVI MK8A

610 305 8641 ASSY,PWB,POWER MF3A

Power Board

610 301 0939 ASSY,PWB,POWER MK8A

For ME3-XU4500, PLC-XU45

MT-POLYEST 0.047U K

MF3-XU4600, PLC-XU46

Transformer

610 305 8658 ASSY,PWB,P.F. MF3A

Board

610 301 0946 ASSY,PWB,P.F. MK8A

610 301 0953 ASSY,PWB,LINE Filter MK8A

Main Board

Line Filter Board

405 014 4608 2SC2412K T146 173 9803 2SC3928A1R 015 8704

IC MM1031XM

SN74AHCT1G14DBVR

C1539 403 164 0204

403 373

C5217 403 164 0204

Network

RB413 645 037 0663 Network 22X4 0.063W R1132

R152 401 8104

R2546 401 105 7909

R336 401 7909

R433 401 105 3901

Fusible

Diode Integrated Circuit

Temp Board

610 304 8932 ASSY,PWB,TEMP ME3A

AC Cord

Accessories

Remote Control

Mechanical Parts List

Optical Parts

67 Red Green Blue

Polarized glass

Optical filterWV

52-a

Model PLC-XU46 Model PLC-XU45

Mechanical Parts List

Chassis Parts

Cabinet Parts Screws

Optical Parts

Page

PLC-XU45

Diagrams & Drawings Schematic Diagrams

Printed Wiring Board Drawings

PLC-XU46

Parts description and reading in schematic diagram

Resistor Reading

Circuit Block Diagram

5VS 5VDVI

5VS

3VS

5VD 9V MCI

DVI Sideb

Printed Wiring Board Diagrams

AV Sidea DVI Sidea

Temp Sidea

Main Sidea

Sidea

Temp Sideb

Main Sideb

Sideb

IC5211

K6R

Power Sidea Power Sideb

K6S

IC671

KEY SW Sideb

KEY SW Sidea

Line Filter Sidea

K6B

A10

IC681

Schematic Diagrams PLC-XU45,46 A11 Left

Line Filter Baord

FA7701V

Schematic Diagrams PLC-XU45,46 A11 Right

Ower Supply

Audio

Schematic Diagrams PLC-XU45,46 A12 Left

IC6171

Schematic Diagrams PLC-XU45,46 A12 Right

TA1318AF

Schematic Diagrams PLC-XU45,46 A13 Left

Digital

Schematic Diagrams PLC-XU45,46 A13 Right

Matri

AD8185ARU

Schematic Diagrams PLC-XU45,46 A14 Left

CG1/CG2-SW

AD8183ARU

Schematic Diagrams PLC-XU45,46 A14 Right

3VS C201 TE201E

IC8001

Schematic Diagrams PLC-XU45,46 A15 Left

IC301

IC1341

Schematic Diagrams PLC-XU45,46 A15 Right

Digital Color Unformity Correction Timing Control

Lamp

Schematic Diagrams PLC-XU45,46 A16 Left

50-52

CPU

Schematic Diagrams PLC-XU45,46 A16 Right

SUB

Memory

Uniformity & Gamma

Schematic Diagrams PLC-XU45,46 A17 Left

Color

Correction

Shift

Schematic Diagrams PLC-XU45,46 A17 Right

Level

Schematic Diagrams PLC-XU45,46 A18 Left

Schematic Diagrams PLC-XU45,46 A18 Right

Pin description of diode, transistor and IC

IC IC