additional safety instructions for drill presses

WEAR YOUR

The operation of any power tool can result in foreign objects being thrown into the _yes, which can result in severe eye damage. Always wear safety goggles complying with ANSI Z87,1 (shown on Package) before commencing power tool operation. Safety Goggles are available at Sears retail or catalog stores.

unpacking checking

CONTENTS

|

|

|

|

|

|

|

|

|

|

|

|

|

| Page |

General |

| Safety | Instructions | for | Power | Tools | ..... | 2 | ||||||

Additional |

| Safety Instructions |

| for | Drill | Presses .... | 3 | |||||||

Unpacking | and | Checking | Contents | ............. |

| 4 | ||||||||

Table | of | Loose | Parts |

|

|

|

|

| 4 | |||||

Motor | Specifications | and Electrical | Requirements.. | 5 | ||||||||||

Assembly | ................................. |

|

|

|

|

|

|

|

|

|

| 6 | ||

| Installing |

| the | Chuck |

|

|

|

| 6 | |||||

| Installing |

| and | Tensioning | Belt |

| 12 | |||||||

Getting |

| to | Know | Your | Drill | Press | .............. |

| 13 | |||||

| Belt | Tension | Rod | ...................... |

|

|

|

| 13 | |||||

| Drilling |

| Speed | ......................... |

|

|

|

|

| 13 | ||||

| Drilling |

| to | Depth | ....................... |

|

|

|

| 14 | ||||

| Removing | the | Chuck | ................... |

|

|

| 15 | ||||||

| Switch | ........................ |

|

|

|

|

| 15 | ||||||

Basic | Drill | Press | Operation |

|

|

|

| 16 | ||||||

| Installing |

| Drills |

|

|

|

|

| 16 | |||||

| Positioning | Table | and | Workpiece | .......... |

| 16 | |||||||

| Feeding |

| ............................. |

|

|

|

|

|

| 17 | ||||

Adjustments |

|

|

| ............................. |

|

|

|

|

|

| 17 | |||

| Depth | Scale | .......................... |

|

|

|

|

| 17 | |||||

| Quil |

| Return | Spring |

|

|

|

| 17 | |||||

| Table | and | Head | Lock | Handles |

| 17 | |||||||

Maintenance |

|

| .............................. |

|

|

|

|

|

|

| 18 | |||

Lubrication |

|

| .............................. |

|

|

|

|

|

|

| 18 | |||

Recommended |

| Accessories | ................... |

|

|

| 18 | |||||||

Trouble | Shooting | .......................... |

|

|

|

|

| 19 | ||||||

Repair |

| Parts | ............................... |

|

|

|

|

|

|

|

| 20 | ||

UNPACKING AND CHECKING CONTENTS

Model No. 113.21371 is shipped complete in one carton but does not include a motor.

Model No.

Separate all parts from packing materials and check each one with the "Table of Loose Parts" to make certain all

items are accounted for, before discarding any packing material.

If any parts are missing, do not attempt to assemble the drill press, plug in the power cord or turn the switch on until the missing parts are obtained and installed correctly.

Remove the protective oil that is applied to the table and column. Use any ordinary household type grease and spo_ remover.

CAUTION: Never use gasoline, naptha or similar highly volatile solvents.

Apply a coat of automobile wax to the table. Wipe a!t parts thoroughly with a clean dry cloth.

contents

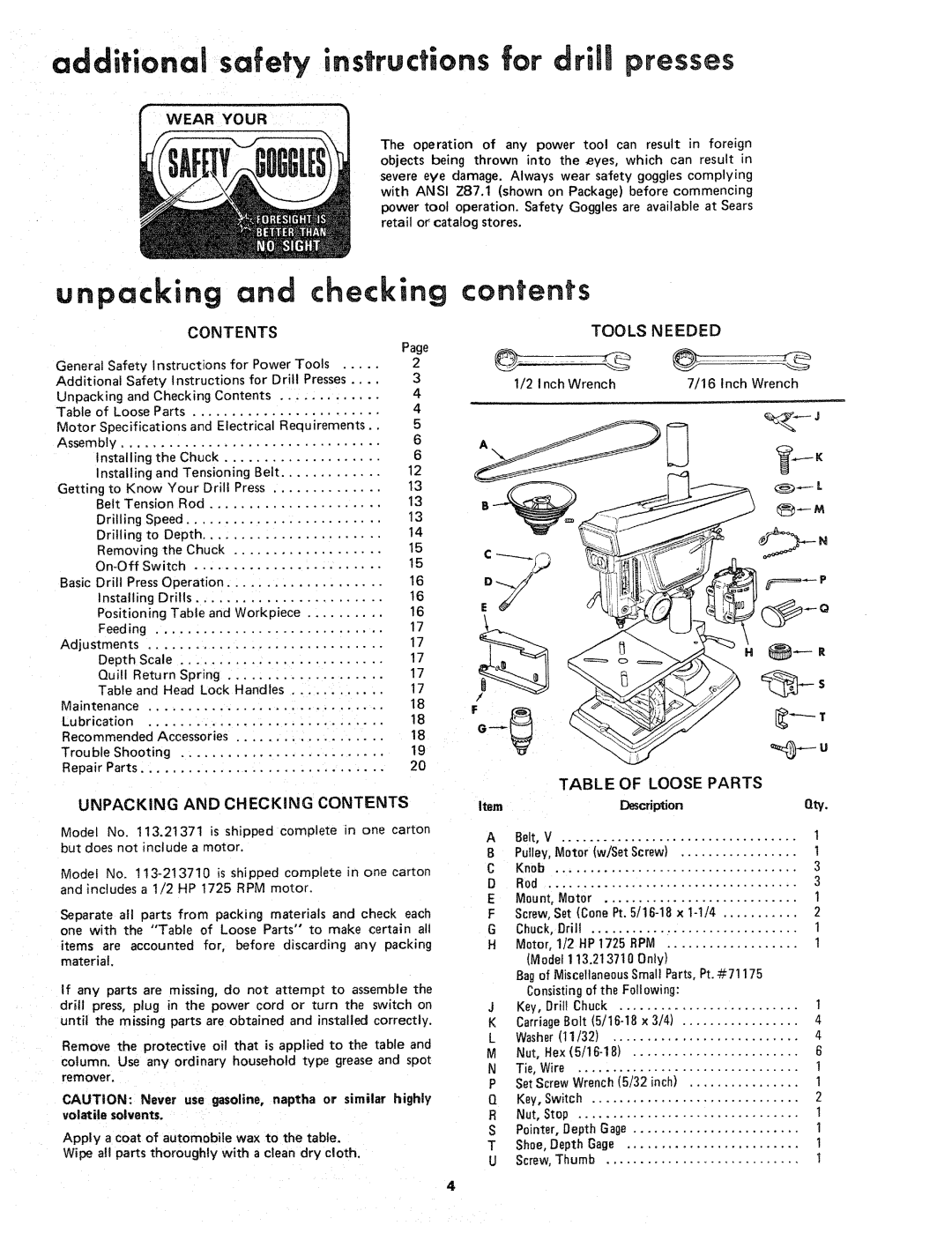

TOOLS NEEDED

1/2 Inch Wrench | 7/16 Inch Wrench |

| TABLE OF LOOSE PARTS |

|

Item | ]Description | Qty. |

A | Belt, V | 1 |

B | Pulley, Motor (wjSet Screw) | ! |

C | Knob | 3 |

D | Rod | 3 |

E | Mount, Motor | 1 |

F | Screw,Set (Cone Pt. | 2 |

G | Chuck, Drill | 1 |

H | Motor, 112 HP1725 BPM | t |

| (Model 1 13.213710 Only) |

|

| Bagof MiscellaneousSmall Parts, Pt. #71175 |

|

| Consistingof the Following: |

|

J | Key, Drill Chuck | 1 |

K | CarriageBolt | 4 |

L | Washer(11/32) | 4 |

M | Nut, Hex | 6 |

N | Tie, Wire | ! |

P | Set Screw Wrench(5/32 inch) | 1 |

Q | Key, Switch | 2 |

R | Nut, Stop | 1 |

S | Pointer, Depth Gage | 1 |

T | Shoe, Depth Gage | 1 |

U | Screw,Thumb | 1 |

4