getting to know your drill press

HEAD LOCK HANDLE ... locks the head to the column.

ALWAYS have it locked in place while operating the drill press.

HEAD SUPPORT COLLAR . .. prevents the head from dropping when the head lock handle is loosened.

ALWAYS have the collar LOCKED into position against

the UNDERSIDE of the head .....

TABLELOCK HANDLE ,, ; locks the table to the column.

ALWAYS have it locked in place while operating the drill p_ess,

ALWAYS hold the table while unlocking it.

TABLE SUPPORT COLLAR ... Prevents the table from

accidently dropping all the way to the bottom when the table lock handle is loosened.

ALWAYS have the collar LOCKED into position

approximately 34 in. from the floor for average drilling operations,

CHUCK KEY . .. is used to tighten or loosen the chuck. It

has a spring loaded EJECTOR pin to "pop" it out of the chuck when you let go of it. When not in use, ALWAYS store the key in the hole in the table.

CHUCK LOCKS NG COLLAR .., draws the chuck onto the spindle nose.

It prevents the chuck from coming loose during operation.

ALWAYS }lave the collar tightened.

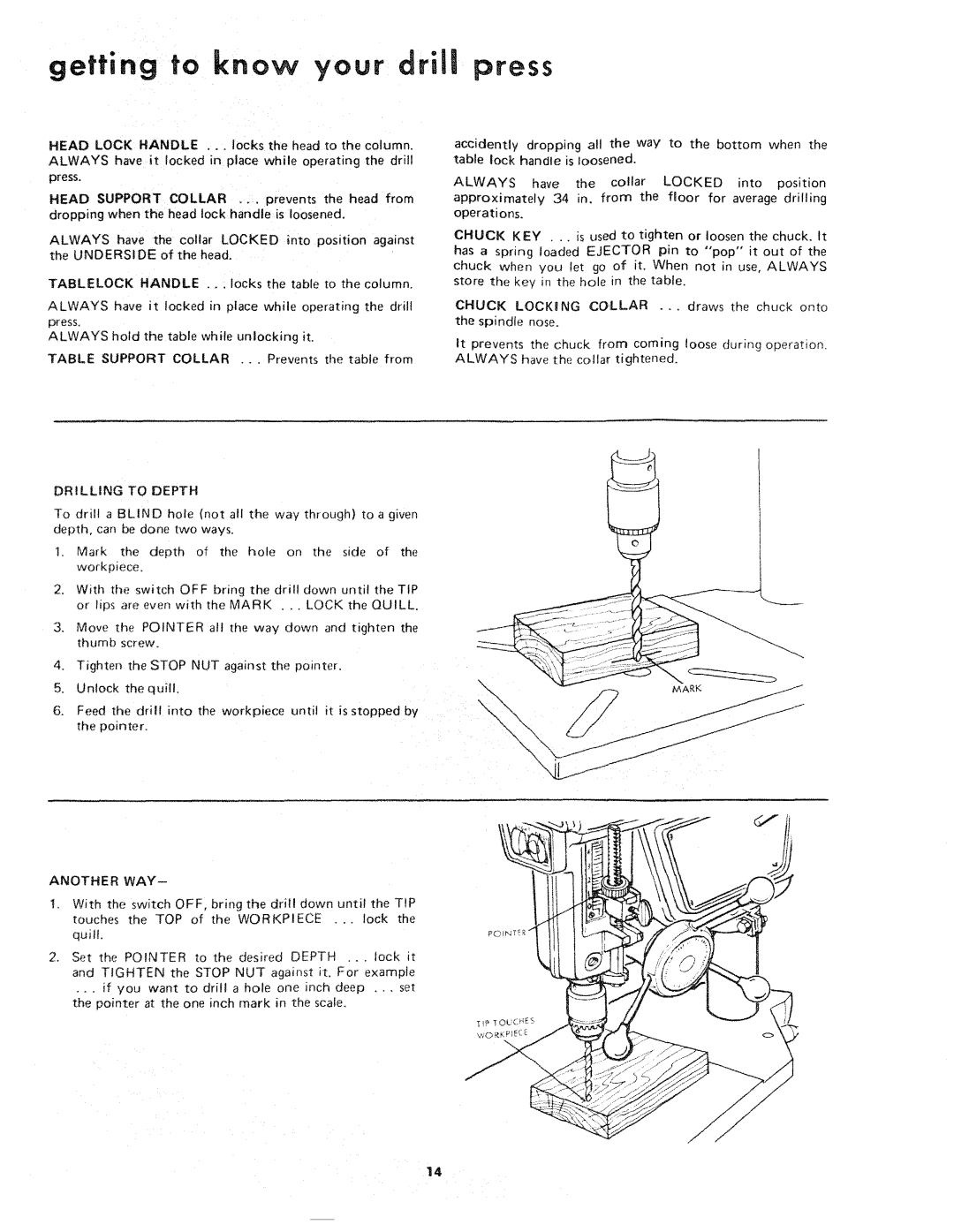

DRILLING TO DEPTH

To drill a BLIND hole (not all the way through) to a given depth, can be done two ways.

I. Mark tile depth of the hole on the side of the workpiece.

2.With the switch OFF bring the drill down until the TIP

or lips are even with the MARK . .. LOCK the QUILL.

3.Move the POINTER all the way down and tighten the thumb screw.

4, | Tighten the STOP NUT against the pointer. |

|

| ||

|

|

| |||

5. | Unlock | the quill. |

| \..., | MARK |

|

| ||||

6. |

|

|

|

|

|

| the pointer. |

|

|

| |

| Feed | thedrillintotheworkpiece | until it is stopped by | \'_.__J |

|

ANOTHER WAY-

!.With the switch OFF, bring the drill down until the TiP

touches the TOP of the WORKPIECE ... lock the quill.

2.Set the POINTER to the desired DEPTH .o. lock it

and TIGHTEN the STOP NUT against it. For example

... if you want to drill a hole one inch deep ... set the pointer at the one inch mark in the scale.

14