USING FEATHERBOARDS

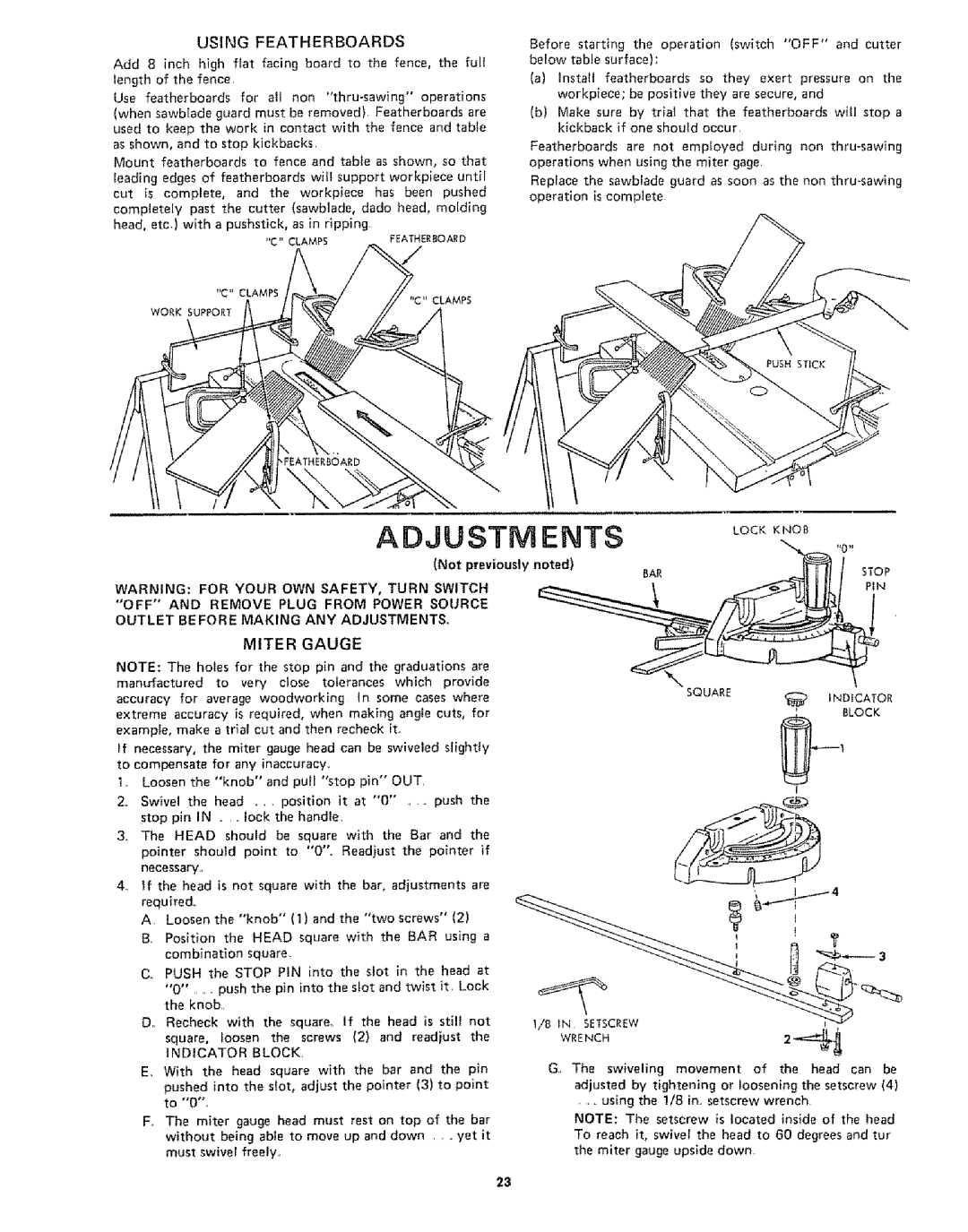

Add 8 inch high flat facing board to the fence, the full length of the fence,

Use featherboards for all non

(when sawb[ade guard must be removed), Featherboards are used to keep the work in contact with the fence and table as shown, and to stop kickbacks.

Mount featherboards to fence and table as shown, so that

leading edges of featherboards wil! support workpiece until

cut is complete, and the workpiece has been pushed

completely past the cutter (sawblade, dado head, molding head, etc.) with a pushstick, as in ripping

"C" CLAMPS | FEATHE_ BOAR D |

| / |

"C" CLAMPS

WORK SUPPORT

Before starting the operation (switch "OFF" and cutter below table surface):

(a) Install featherboards so they exert pressure on the workpiece; be positive they are secure, and

(b)Make sure by trial that the featherboards will stop a kickback if one should occur,

Featherboards are not employed during non

Replace the sawbtade guard as soon as the non

|

|

|

| ADJUSTMENTS |

| OCK.OB | ||

|

|

|

|

|

|

|

| |

|

|

|

|

| (Not previously | noted) | BAR | STOP |

|

|

|

|

|

|

|

| PIN |

WARNING: | FOR YOUR | OWN | SAFETY, | TURN | SWITCH | _ | _ | |

"OFF" AND | REMOVE | PLUG | FROM | POWER | SOURCE |

| _ | : |

OUTLET BEFORE MAKING ANY ADJUSTMENTS.

MITER GAUGE

NOTE: The holes for the stop pin and the graduations are

manufactured to very close tolerances which provide

accuracy for average woodworking In some cases where extreme accuracy is required, when making angle cuts, for example, make a trial cut and then recheck it.

If necessary, the miter gauge head can be swiveled slightly to compensate for any inaccuracy.,

1.Loosen the "knob" and pul! "stop pin'" OUT,

2.Swivel the head .... position it at "0" . . push the stop pin IN ..... lock the handle,

3.The HEAD should be square with the Bar and the pointer should point to "0",, Readjust the pointer if necessary.

4.If the head is not square with the bar, adjustments are require&

A, Loosen the "knob" (1) and the "two screws" (2)

B Position the HEAD square with the BAR using a

combination square,

C, PUSH the STOP PIN into the slot in the head at "0" ,.... push the pin into the slot and twist it, Lock the knob,,

Do Recheck with the square,, if the head is still not square, loosen the screws (2) and readjust the

INDICATOR BLOCK,

E, With the head square with the bar and the pin pushed into the slot, adjust the pointer (3) to point to "0",

Fo The miter gauge head must rest on top of the bar

without being able to move up and down .... yet it

must swivel freely,

SQUAF:E

INDICATOR

BLOCK

I

WRENCH |

|

| 2 |

|

|

|

| _ |

|

| |

G, The swiveling | movement | of the | head can | be | |

adjusted by tightening | or | loosening | the setscrew | (4) | |

..... using the !/8 in., setscrew wrench

NOTE: The setscrew is located inside of the head To reach it, swivel the head to 60 degrees and tur the miter gauge upside down.

23