5Althoughthemotorisdesignedfor operationon the voltageandfrequencyspecifiedon motornameplate, normalloadswill be handledsafelyon voltagesnot morethan10%aboveorbelowthenameplatevoltage. Heavyloads,however,requirethatvoltageat motor terminalsbe not lessthanthe voltagespecifiedon

nameplate

6Mostmotortroublesmay be tracedto looseor incorrect connections,overloading,reducedinput voltage(whichresultswhensmallsizewiresareusedin the supplycircuit)or whenthe supplycircuit is extremelylong.Alwayscheckconnections,loadand

supply circuit when the motor fails to perform

satisfactorily Check wire sizes and lengths with the table in the next paragraph° Replace or repair damaged or worn cord immediately.

CONNECTING TO POWER SOURCE OUTLET

This saw must be grounded while in use to protect the operator from electrical shock

If power cord is worn or cut, or damaged in any way, have it replaced immediately

CAUTION: This saw is wired for operation on 240 volts only, Connect to a 15 ampere branch circuit protected by a 15 ampere time delay or circuit saver fuse or circuit breaker,

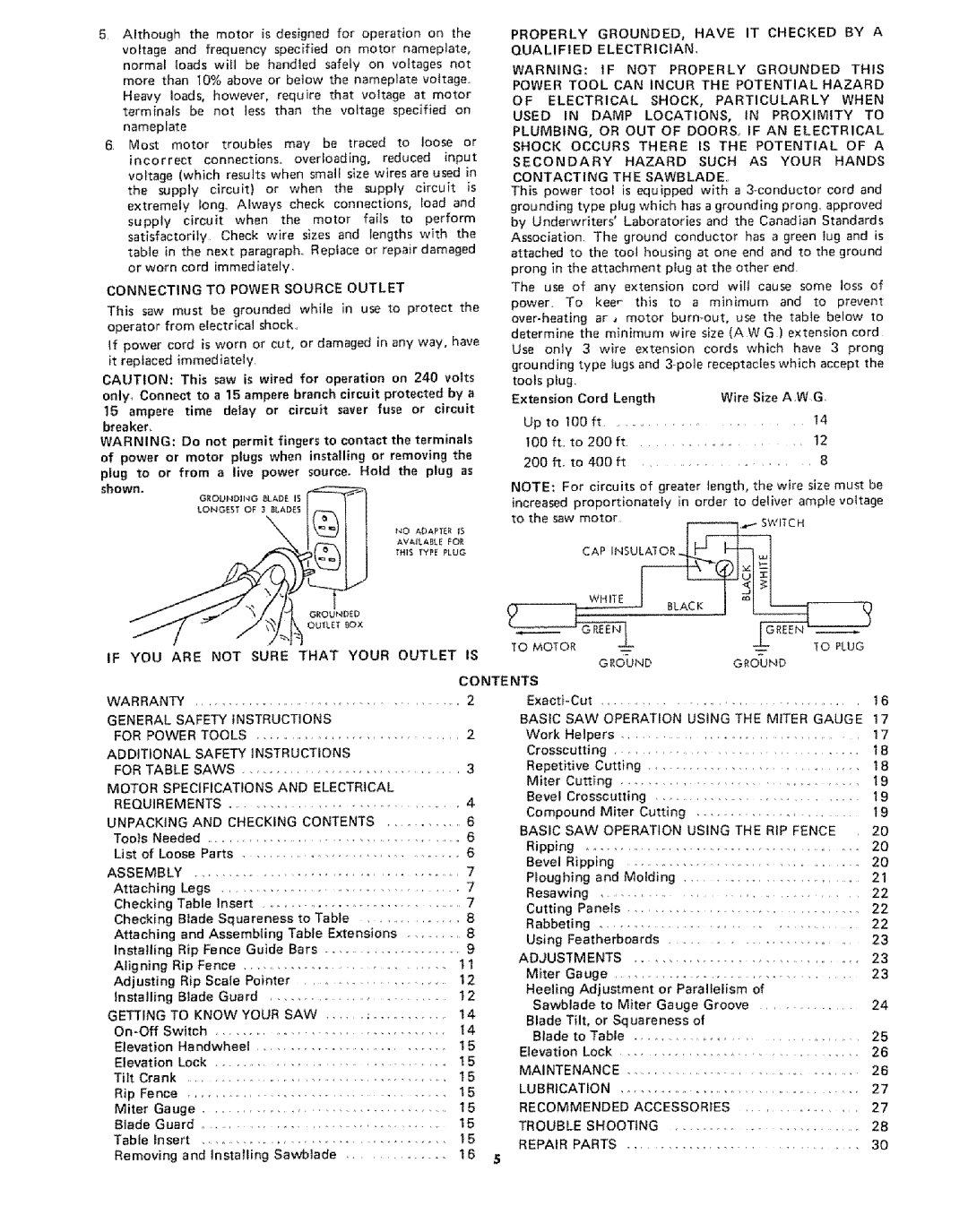

WARNING: Do not permit fingers to contact the terminals of power or motor plugs when installing or removing the plug to or from a live power source. Hold the plug as

shown.

O,OUND_NG_LADE_s

LONGEST OF 3 _LADES

t40 ADAPTER IS AVAILABLE FOR

THIS TYPE PLUG

GROUNDED

OUTLET _OX

PROPERLY | GROUNDED, | HAVE | IT | CHECKED |

| BY | A | ||

QUALIFIED | ELECTRICIAN. |

|

|

|

|

|

| ||

WARNING: | tF NOT PROPERLY | GROUNDED |

| THIS | |||||

POWER | TOOL CAN | INCUR | THE POTENTIAL | HAZARD | |||||

OF ELECTRICAL | SHOCK, | PARTICULARLY |

| WHEN | |||||

USED | IN | DAMP | LOCATIONS, | IN | PROXIMITY |

| TO | ||

PLUMBING, | OR OUT OF DOORS., IF AN ELECTRICAL |

| |||||||

SHOCK | OCCURS | THERE | IS THE | POTENTIAL |

| OF | A | ||

SECONDARY | HAZARD | SUCH | AS | YOUR |

| HANDS | |||

CONTACTING | THE | SAWBLADE. |

|

|

|

|

| ||

This power | tool | is | equipped | with | a 3_conductor | cord and | ||

grounding | type plug | which | has a grounding | prong, | approved | |||

by Underwriters' | Laboratories | and | the Canadian | Standards | ||||

Association | The | ground | conductor | has | a green | lug and is | ||

attached to the tool housing at one end and to the ground

prong | in | the | attachment | plug | at | the | other | end |

| |||||

The | use | of |

| any | extension | cord | will | cause some loss of | ||||||

power |

| To |

| kee_ | this | to | a | minimum |

| and to | prevent | |||

| ar, |

| motor | use the | table | below to | ||||||||

determine | the | minimum | wire | size | (A | W | G ) extension cord | |||||||

Use | only | 3 | wire | extension | cords | which | have | 3 prong | ||||||

grounding | type | tugs and | 3pole | receptacles | which accept the | |||||||||

tools | plug |

|

|

|

|

|

|

|

|

|

|

|

| |

Extension | Cord | Length |

|

| Wire | Size | AWG |

| ||||||

Up | to | 100 | ft |

|

|

|

|

| 14 |

| ||||

I00 | fL | to | 200 | ft |

|

|

|

| 12 |

| ||||

200 | ft. | to | 400 | ft | ................... |

|

|

|

| 8 |

| |||

NOTE: For circuits of greater length, the wire size must be

increased proportionately in order to deliver ample voltage

IF YOU ARE |

| NOT | SURE | THAT | YOUR OUTLET | IS |

|

|

| GROUND |

| G{_OUND |

| ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

| CONTENTS |

|

|

|

|

|

|

|

|

| ||

WARRANTY |

|

|

|

|

|

|

|

|

| 2 |

| .................................. |

|

|

|

| 16 | ||||||

GENERAL | SAFETY | INSTRUCTIONS |

|

| BASIC | SAW | OPERATION | USING | THE | MITER GAUGE | 17 | ||||||||||||

FOR | POWER | TOOLS | ................................... |

|

|

| 2 | Work | Helpers | ....................................... |

|

|

| 17 | |||||||||

ADDITIONAL | SAFETY | INSTRUCTIONS |

| Crosscutting |

|

| ................................... |

|

|

| 18 | ||||||||||||

FOR | TABLE SAWS |

|

|

|

|

|

| 3 | Repetitive |

| Cutting | ................................ |

|

| 18 | ||||||||

................................. |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

MOTOR | SPECIFICATIONS | AND | ELECTRICAL |

| Miter | Cutting | ...................................... |

|

|

| 19 | ||||||||||||

| Bevel | Crosscutting |

|

|

|

| 19 | ||||||||||||||||

REQUIREMENTS |

|

|

|

|

|

|

| 4 | ............................. |

|

| ||||||||||||

|

|

|

|

|

|

| Compound |

| Miter | Cutting |

|

|

| I9 | |||||||||

UNPACKING | AND | CHECKING | CONTENTS | 6 |

| .................... |

| ||||||||||||||||

BASIC | SAW | OPERATION | USING | THE | RIP FENCE | 20 | |||||||||||||||||

Tools Needed |

| ......................................... |

|

|

|

|

| 6 | |||||||||||||||

List | of | Loose | Parts |

|

|

|

|

|

| 6 | Ripping | .......................................... |

|

|

|

|

|

| 20 | ||||

|

|

|

|

|

| Bevel | Ripping |

|

|

|

| 20 | |||||||||||

ASSEMBLY |

|

|

|

|

|

|

|

|

| 7 |

|

|

| ||||||||||

....................................... |

|

|

|

|

|

|

| Ploughing |

| and Molding |

|

|

| 21 | |||||||||

Attaching | Legs |

|

|

|

|

|

|

| 7 |

|

|

|

| ||||||||||

.................................... |

|

|

|

|

| Resawing |

|

|

|

|

|

|

| 22 | |||||||||

Checking | Table | Insert |

|

|

|

|

| 7 |

| ................................ |

|

|

|

| |||||||||

................................ |

|

|

| Cutting | Panels |

|

|

|

|

| 22 | ||||||||||||

Checking | Blade | Squareness | to | Table | 8 | ................................. |

|

|

| ||||||||||||||

Rabbeting |

|

|

|

|

|

|

| 22 | |||||||||||||||

Attaching | and | Assembling |

| Table | Extensions | 8 |

| ................................. |

|

|

|

| |||||||||||

| Using | Featherboards |

|

|

| 23 | |||||||||||||||||

installing | Rip | Fence | Guide | Bars |

|

| 9 |

|

| ||||||||||||||

.................... | ADJUSTMENTS |

|

|

|

|

| 23 | ||||||||||||||||

Aligning |

| Rip | Fence |

|

|

|

|

| 11 |

| ................................. |

|

| ||||||||||

|

|

|

|

| Miter | Gauge |

|

|

|

|

| 23 | |||||||||||

Adjusting | Rip |

| Scale | Pointer |

|

|

| 12 | .................................. |

|

|

| |||||||||||

| ......................... |

| Heeling | Adjustment | or | Parallelism | of |

|

| ||||||||||||||

Installing | Blade | Guard |

|

|

|

| 12 |

|

| ||||||||||||||

|

|

| Sawblade |

| to | Miter Gauge Groove |

| 24 | |||||||||||||||

GETTING TO KNOW YOUR SAW |

|

| 14 |

| |||||||||||||||||||

.................. | Blade Tilt, | or | Squareness | of |

|

|

| ||||||||||||||||

Switch |

|

|

|

|

|

|

|

| 14 |

|

|

| |||||||||||

| ............................... |

|

|

|

|

| Blade | to |

| Table |

|

|

|

| 25 | ||||||||

Elevation | Handwheel |

|

|

|

|

| 1 5 |

| .................................. |

|

| ||||||||||||

............................. |

|

|

| Elevation | Lock |

|

|

|

|

| 26 | ||||||||||||

Elevation | Lock |

|

|

|

|

|

|

| 15 | ................................. |

|

|

| ||||||||||

................................... |

|

|

|

|

| MAINTENANCE |

|

|

|

|

| 26 | |||||||||||

Tilt | Crank |

|

|

|

|

|

|

|

|

| 15 |

|

|

|

|

| |||||||

...................................... |

|

|

|

|

|

|

| LUBRICATION |

|

|

|

|

| 27 | |||||||||

Rip | Fence |

|

|

|

|

|

|

|

|

|

| ........................................ |

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

Miter | Gauge | .................................... |

|

|

|

|

|

| 15 | RECOMMENDED |

| ACCESSORIES | ............... | 27 | |||||||||

Blade | Guard |

| ..................................... |

|

|

|

|

| I 5 | TROUBLE | SHOOTING |

|

| 28 | |||||||||

Table | Insert | ...................................... |

|

|

|

|

|

| 15 | REPAIR | PARTS |

|

|

|

|

| 30 | ||||||

|

|

|

|

|

|

|

|

|

|

|

|

| ............................ |

|

|

| |||||||

Removing | and | Installing | Sawblade | .............. | 1 6 |

|

|

|

|

|

|

|

|

|

| ||||||||