LUBRnCATUON

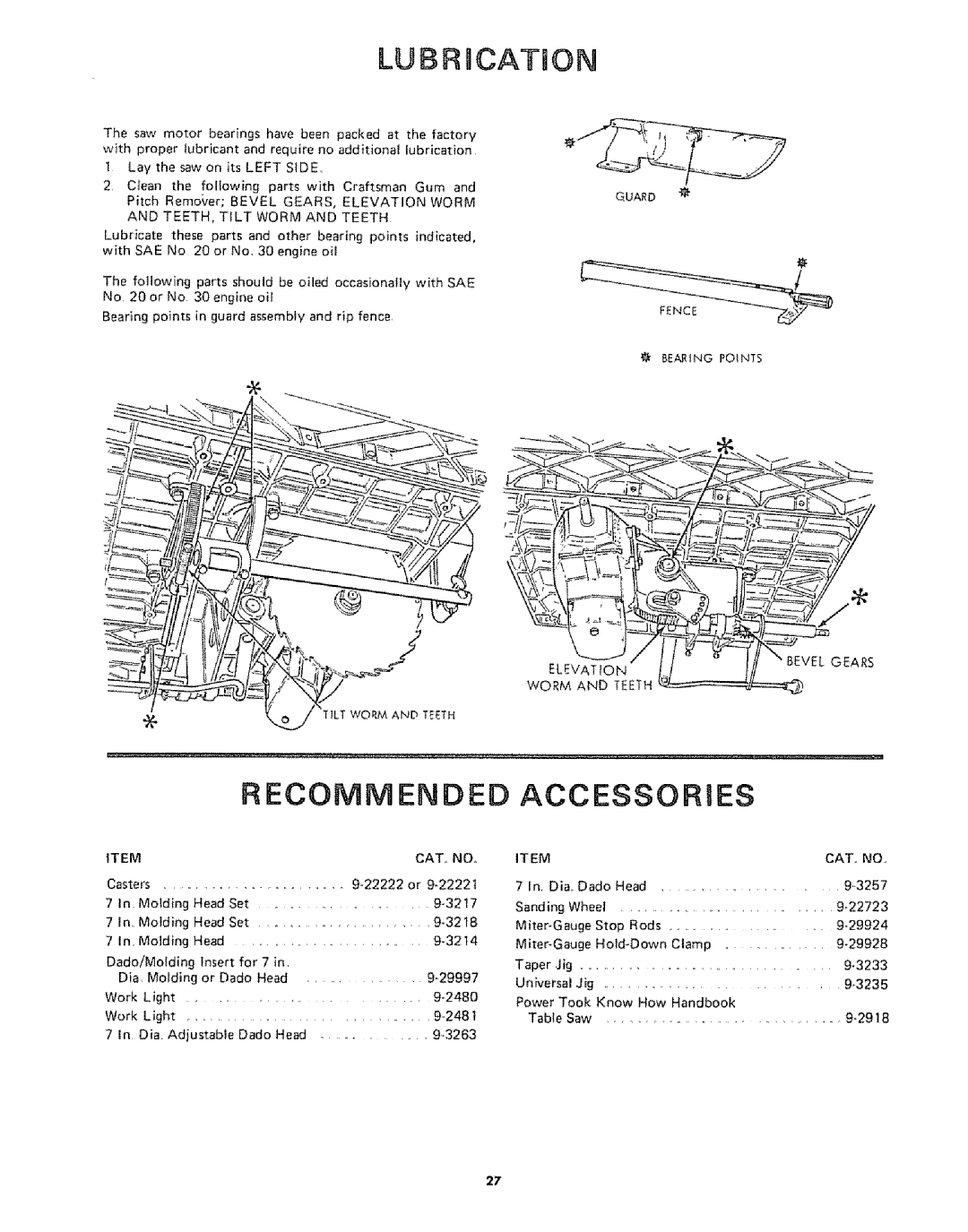

The saw motor bearings have been packed at the factory

with proper lubricant and require no additional {ubrication 1 Lay the saw on its LEFT SIDE.

2 Ciean the folfowing parts with Craftsman Gum and

Pitch RemoVer; BEVEL GEARS, ELEVATION WORM AND TEETH, T_LT WORM AND TEETH

Lubricate these parts and other bearing points indicated, with SAE No 20 or No. 30 engine oi!

The following parts should be oiled occasionally with SAE No 20 or No 30 engine oil

Bearing points in guard assembly and rip fence

GUARD _"

BEARING POINTS

\ BEVEL GEARS

ELEVATION

WORM AND TEETH

,_. | TILT WORM AND TE_TH |

RECOMMENDED ACCESSORIES

ITEM |

|

|

|

|

| CAT., NO. | ITEM |

|

|

| CAT.. NO | |

Casters |

|

|

| 7 In. Diao Dado Head | ............................ | 9..3257 | ||||||

7 | In | Motding | Head | Set | ............................ | Sanding | Wheel |

| ||||

|

|

|

|

|

|

|

| |||||

7 | In | Molding | Head | Set | ........................ | Stop Rods |

| |||||

|

|

|

|

|

|

|

| ............................. | ||||

7 | In. | Molding | Head |

| ........................ | Clamp | ||||||

|

|

|

|

|

|

|

| |||||

Dado/Molding | Insert | for | 7 | in. |

| Taper | Jig |

|

| |||

|

|

|

|

|

|

|

| .................................. | ||||

| Die | Molding | or Dado | Head | .................9-29997 | Universal | Jig | |||||

|

|

|

|

|

|

|

| |||||

Work | Light |

|

|

| Power Took Know How Handbook |

| ||||||

|

|

|

|

|

|

|

|

| ||||

Work | Light |

|

|

| Table | Saw | ||||||

7 | in Dia. Adjustable | Dado | Head | .............9.,3263 |

|

|

|

|

| |||

27