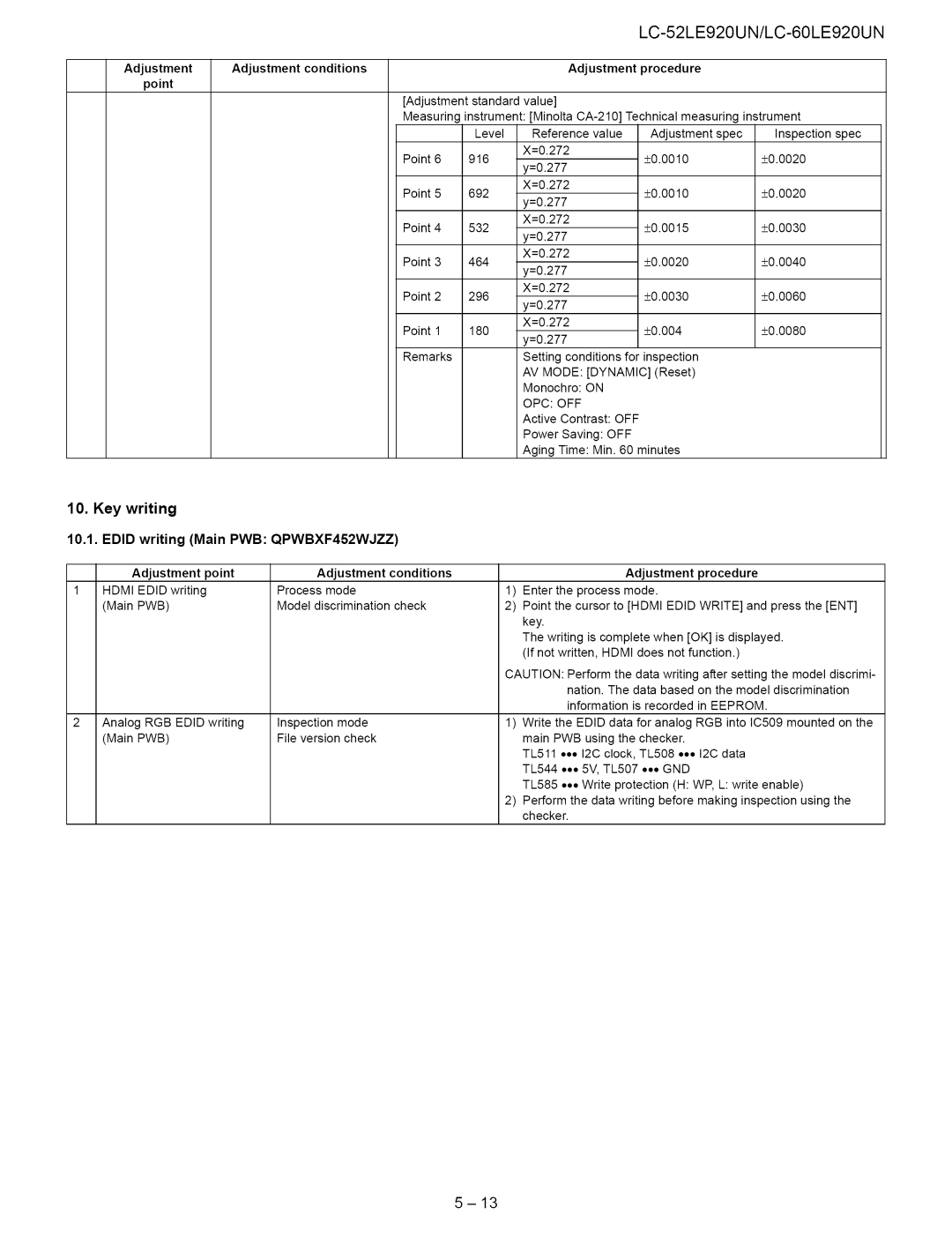

LC-52LE920UN/LC-60LE920UN

Adjustment | Adjustment conditions |

|

|

| Adjustment | procedure |

| ||

point |

|

|

|

|

|

|

|

|

|

| [Adjustment | standard | value] |

|

|

|

|

| |

| Measuring instrument: [Minolta | ||||||||

|

|

| Level | Reference | value | Adjustment spec | Inspection spec | ||

| Point | 6 | 916 | X=0.272 |

|

| ±0.0010 | ±0.0020 | |

| y=0.277 |

|

| ||||||

|

|

|

|

|

|

|

| ||

| Point | 5 | 692 | X=0.272 |

|

| ±0.0010 | ±0.0020 | |

| y=0.277 |

|

| ||||||

|

|

|

|

|

|

|

| ||

| Point | 4 | 532 | X=0.272 |

|

| ±0.0015 | ±0.0030 | |

| y=0.277 |

|

| ||||||

|

|

|

|

|

|

|

| ||

| Point | 3 | 464 | X=0.272 |

|

| ±0.0020 | ±0.0040 | |

| y=0.277 |

|

| ||||||

|

|

|

|

|

|

|

| ||

| Point | 2 | 296 | X=0.272 |

|

| ±0.0030 | ±0.0060 | |

| y=0.277 |

|

| ||||||

|

|

|

|

|

|

|

| ||

| Point | 1 | 180 | X=0.272 |

|

| ±0.004 | ±0.0080 | |

| y=0.277 |

|

| ||||||

|

|

|

|

|

|

|

| ||

| Remarks |

| Setting | conditions | for | inspection |

| ||

|

|

|

| AV MODE: [DYNAMIC] (Reset) |

| ||||

|

|

|

| Monochro: | ON |

|

|

| |

|

|

|

| OPC: OFF |

|

|

|

| |

|

|

|

| Active | Contrast: | OFF |

|

| |

|

|

|

| Power | Saving: OFF |

|

| ||

|

|

|

| Aging Time: Min. 60 minutes |

| ||||

10. Key writing

10.1. EDID writing (Main PWB: QPWBXF452WJZZ)

Adjustment point | Adjustment | conditions |

HDMI EDID writing | Process mode |

|

(Main PWB) | Model discrimination | check |

Analog | RGB EDID writing | Inspection | mode |

(Main | PWB) | File version | check |

Adjustment procedure

1)Enter the process mode.

2)Point the cursor to [HDMI EDID WRITE] and press the [ENT] key.

The writing is complete when [OK] is displayed. (If not written, HDMI does not function.)

CAUTION: Perform the data writing after setting the model discrimi- nation. The data based on the model discrimination information is recorded in EEPROM.

1)Write the EDID data for analog RGB into IC509 mounted on the main PWB using the checker.

TL511 *** 12C clock, TL508 *** 12C data TL544 *** 5V, TL507 *** GND

TL585 °°° Write protection (H: WP, L: write enable)

2)Perform the data writing before making inspection using the checker.