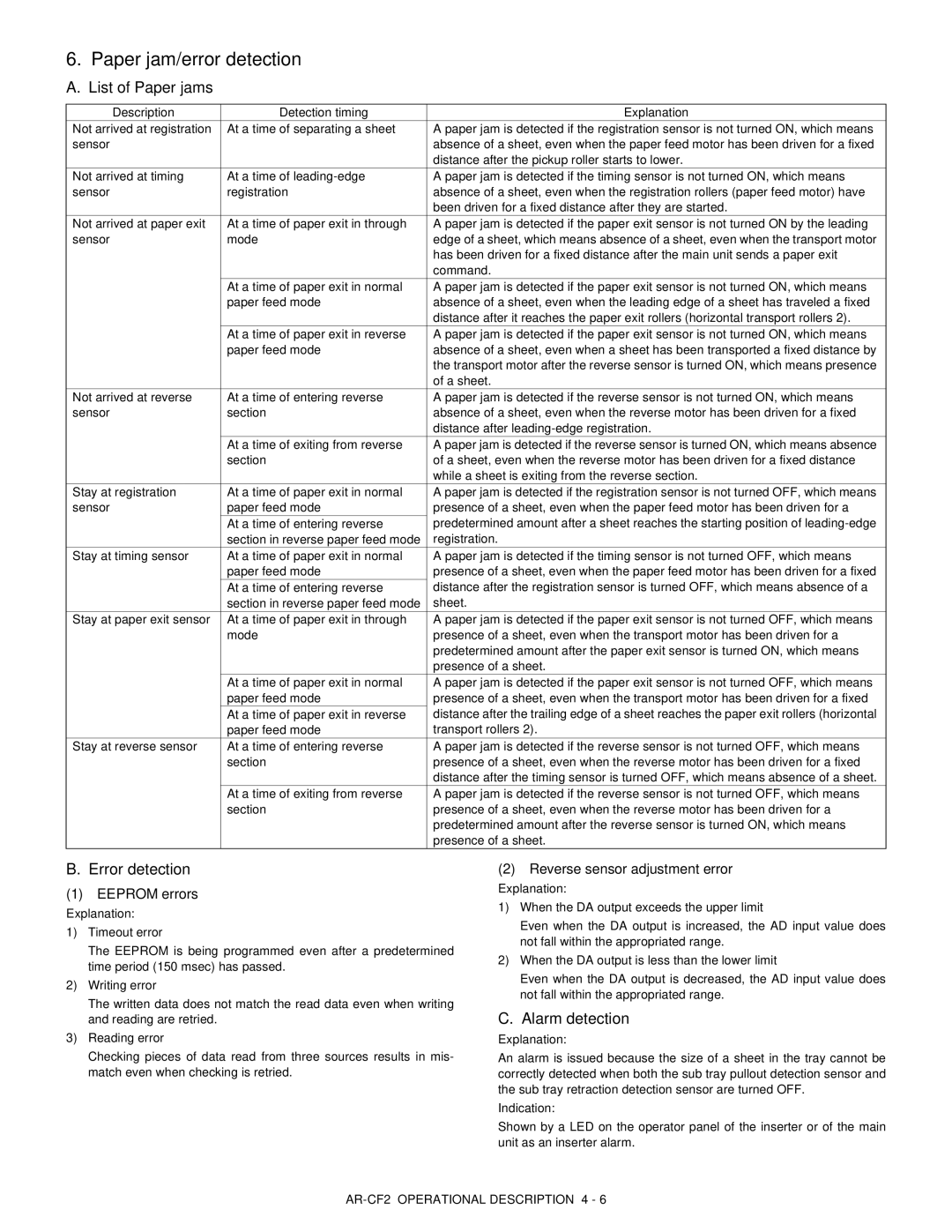

6. Paper jam/error detection

A. List of Paper jams

Description | Detection timing | Explanation |

Not arrived at registration | At a time of separating a sheet | A paper jam is detected if the registration sensor is not turned ON, which means |

sensor |

| absence of a sheet, even when the paper feed motor has been driven for a fixed |

|

| distance after the pickup roller starts to lower. |

Not arrived at timing | At a time of | A paper jam is detected if the timing sensor is not turned ON, which means |

sensor | registration | absence of a sheet, even when the registration rollers (paper feed motor) have |

|

| been driven for a fixed distance after they are started. |

Not arrived at paper exit | At a time of paper exit in through | A paper jam is detected if the paper exit sensor is not turned ON by the leading |

sensor | mode | edge of a sheet, which means absence of a sheet, even when the transport motor |

|

| has been driven for a fixed distance after the main unit sends a paper exit |

|

| command. |

| At a time of paper exit in normal | A paper jam is detected if the paper exit sensor is not turned ON, which means |

| paper feed mode | absence of a sheet, even when the leading edge of a sheet has traveled a fixed |

|

| distance after it reaches the paper exit rollers (horizontal transport rollers 2). |

| At a time of paper exit in reverse | A paper jam is detected if the paper exit sensor is not turned ON, which means |

| paper feed mode | absence of a sheet, even when a sheet has been transported a fixed distance by |

|

| the transport motor after the reverse sensor is turned ON, which means presence |

|

| of a sheet. |

Not arrived at reverse | At a time of entering reverse | A paper jam is detected if the reverse sensor is not turned ON, which means |

sensor | section | absence of a sheet, even when the reverse motor has been driven for a fixed |

|

| distance after |

| At a time of exiting from reverse | A paper jam is detected if the reverse sensor is turned ON, which means absence |

| section | of a sheet, even when the reverse motor has been driven for a fixed distance |

|

| while a sheet is exiting from the reverse section. |

Stay at registration | At a time of paper exit in normal | A paper jam is detected if the registration sensor is not turned OFF, which means |

sensor | paper feed mode | presence of a sheet, even when the paper feed motor has been driven for a |

| At a time of entering reverse | predetermined amount after a sheet reaches the starting position of |

| section in reverse paper feed mode | registration. |

Stay at timing sensor | At a time of paper exit in normal | A paper jam is detected if the timing sensor is not turned OFF, which means |

| paper feed mode | presence of a sheet, even when the paper feed motor has been driven for a fixed |

| At a time of entering reverse | distance after the registration sensor is turned OFF, which means absence of a |

| section in reverse paper feed mode | sheet. |

Stay at paper exit sensor | At a time of paper exit in through | A paper jam is detected if the paper exit sensor is not turned OFF, which means |

| mode | presence of a sheet, even when the transport motor has been driven for a |

|

| predetermined amount after the paper exit sensor is turned ON, which means |

|

| presence of a sheet. |

| At a time of paper exit in normal | A paper jam is detected if the paper exit sensor is not turned OFF, which means |

| paper feed mode | presence of a sheet, even when the transport motor has been driven for a fixed |

| At a time of paper exit in reverse | distance after the trailing edge of a sheet reaches the paper exit rollers (horizontal |

| paper feed mode | transport rollers 2). |

Stay at reverse sensor | At a time of entering reverse | A paper jam is detected if the reverse sensor is not turned OFF, which means |

| section | presence of a sheet, even when the reverse motor has been driven for a fixed |

|

| distance after the timing sensor is turned OFF, which means absence of a sheet. |

| At a time of exiting from reverse | A paper jam is detected if the reverse sensor is not turned OFF, which means |

| section | presence of a sheet, even when the reverse motor has been driven for a |

|

| predetermined amount after the reverse sensor is turned ON, which means |

|

| presence of a sheet. |

B. Error detection

(1)EEPROM errors

Explanation:

1)Timeout error

The EEPROM is being programmed even after a predetermined time period (150 msec) has passed.

2)Writing error

The written data does not match the read data even when writing and reading are retried.

3)Reading error

Checking pieces of data read from three sources results in mis- match even when checking is retried.

(2)Reverse sensor adjustment error

Explanation:

1)When the DA output exceeds the upper limit

Even when the DA output is increased, the AD input value does not fall within the appropriated range.

2)When the DA output is less than the lower limit

Even when the DA output is decreased, the AD input value does not fall within the appropriated range.

C. Alarm detection

Explanation:

An alarm is issued because the size of a sheet in the tray cannot be correctly detected when both the sub tray pullout detection sensor and the sub tray retraction detection sensor are turned OFF.

Indication:

Shown by a LED on the operator panel of the inserter or of the main unit as an inserter alarm.