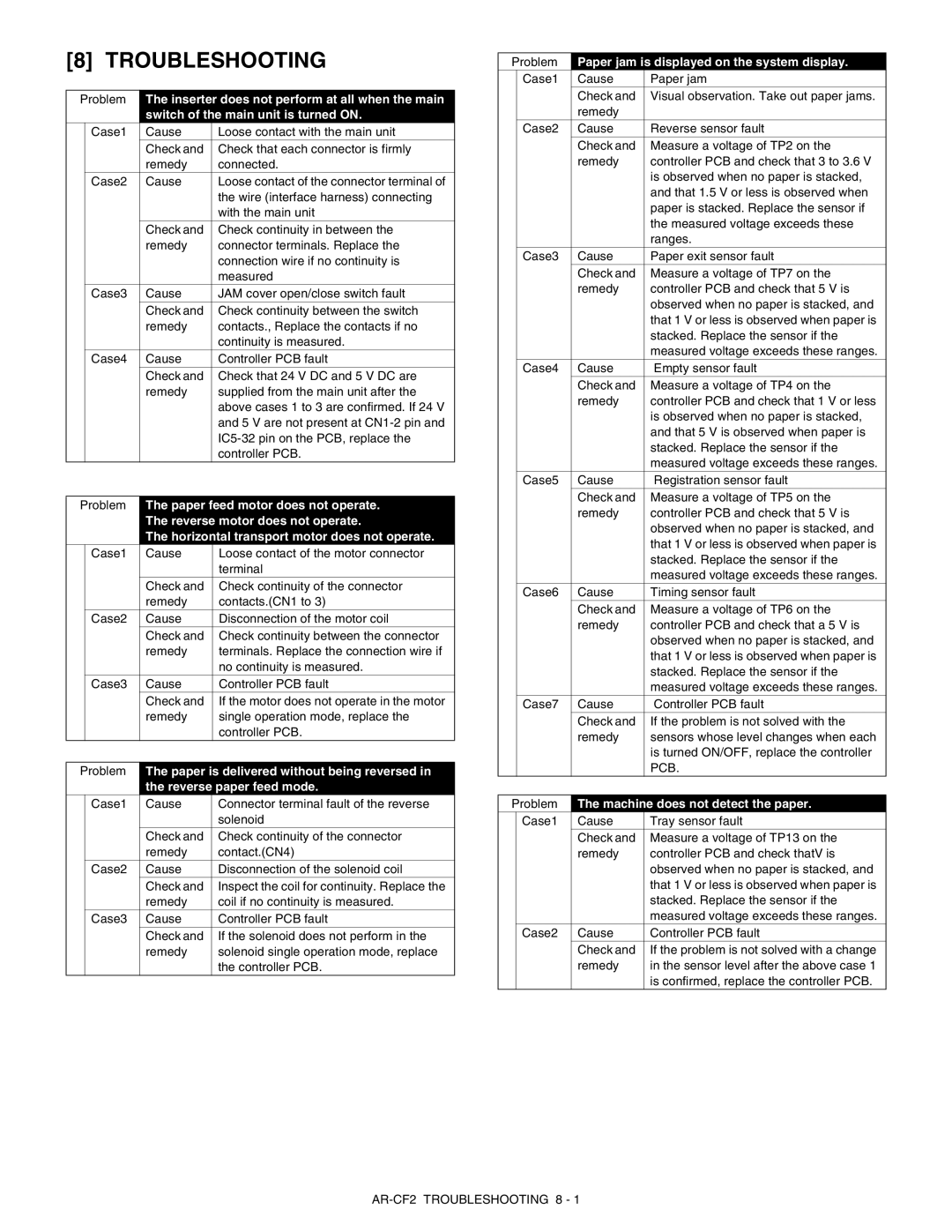

[8] TROUBLESHOOTING

Problem | The inserter does not perform at all when the main | ||

|

| switch of the main unit is turned ON. | |

| Case1 | Cause | Loose contact with the main unit |

|

| Check and | Check that each connector is firmly |

|

| remedy | connected. |

| Case2 | Cause | Loose contact of the connector terminal of |

|

|

| the wire (interface harness) connecting |

|

|

| with the main unit |

|

| Check and | Check continuity in between the |

|

| remedy | connector terminals. Replace the |

|

|

| connection wire if no continuity is |

|

|

| measured |

| Case3 | Cause | JAM cover open/close switch fault |

|

| Check and | Check continuity between the switch |

|

| remedy | contacts., Replace the contacts if no |

|

|

| continuity is measured. |

| Case4 | Cause | Controller PCB fault |

|

| Check and | Check that 24 V DC and 5 V DC are |

|

| remedy | supplied from the main unit after the |

|

|

| above cases 1 to 3 are confirmed. If 24 V |

|

|

| and 5 V are not present at |

|

|

| |

|

|

| controller PCB. |

Problem | The paper feed motor does not operate. | ||

|

| The reverse motor does not operate. | |

|

| The horizontal transport motor does not operate. | |

| Case1 | Cause | Loose contact of the motor connector |

|

|

| terminal |

|

| Check and | Check continuity of the connector |

|

| remedy | contacts.(CN1 to 3) |

| Case2 | Cause | Disconnection of the motor coil |

|

| Check and | Check continuity between the connector |

|

| remedy | terminals. Replace the connection wire if |

|

|

| no continuity is measured. |

| Case3 | Cause | Controller PCB fault |

|

| Check and | If the motor does not operate in the motor |

|

| remedy | single operation mode, replace the |

|

|

| controller PCB. |

Problem | The paper is delivered without being reversed in | ||

|

| the reverse paper feed mode. | |

| Case1 | Cause | Connector terminal fault of the reverse |

|

|

| solenoid |

|

| Check and | Check continuity of the connector |

|

| remedy | contact.(CN4) |

| Case2 | Cause | Disconnection of the solenoid coil |

|

| Check and | Inspect the coil for continuity. Replace the |

|

| remedy | coil if no continuity is measured. |

| Case3 | Cause | Controller PCB fault |

|

| Check and | If the solenoid does not perform in the |

|

| remedy | solenoid single operation mode, replace |

|

|

| the controller PCB. |

Problem | Paper jam is displayed on the system display. | ||

| Case1 | Cause | Paper jam |

|

| Check and | Visual observation. Take out paper jams. |

|

| remedy |

|

| Case2 | Cause | Reverse sensor fault |

|

| Check and | Measure a voltage of TP2 on the |

|

| remedy | controller PCB and check that 3 to 3.6 V |

|

|

| is observed when no paper is stacked, |

|

|

| and that 1.5 V or less is observed when |

|

|

| paper is stacked. Replace the sensor if |

|

|

| the measured voltage exceeds these |

|

|

| ranges. |

| Case3 | Cause | Paper exit sensor fault |

|

| Check and | Measure a voltage of TP7 on the |

|

| remedy | controller PCB and check that 5 V is |

|

|

| observed when no paper is stacked, and |

|

|

| that 1 V or less is observed when paper is |

|

|

| stacked. Replace the sensor if the |

|

|

| measured voltage exceeds these ranges. |

| Case4 | Cause | Empty sensor fault |

|

| Check and | Measure a voltage of TP4 on the |

|

| remedy | controller PCB and check that 1 V or less |

|

|

| is observed when no paper is stacked, |

|

|

| and that 5 V is observed when paper is |

|

|

| stacked. Replace the sensor if the |

|

|

| measured voltage exceeds these ranges. |

| Case5 | Cause | Registration sensor fault |

|

| Check and | Measure a voltage of TP5 on the |

|

| remedy | controller PCB and check that 5 V is |

|

|

| observed when no paper is stacked, and |

|

|

| that 1 V or less is observed when paper is |

|

|

| stacked. Replace the sensor if the |

|

|

| measured voltage exceeds these ranges. |

| Case6 | Cause | Timing sensor fault |

|

| Check and | Measure a voltage of TP6 on the |

|

| remedy | controller PCB and check that a 5 V is |

|

|

| observed when no paper is stacked, and |

|

|

| that 1 V or less is observed when paper is |

|

|

| stacked. Replace the sensor if the |

|

|

| measured voltage exceeds these ranges. |

| Case7 | Cause | Controller PCB fault |

|

| Check and | If the problem is not solved with the |

|

| remedy | sensors whose level changes when each |

|

|

| is turned ON/OFF, replace the controller |

|

|

| PCB. |

Problem | The machine does not detect the paper. | ||

| Case1 | Cause | Tray sensor fault |

|

| Check and | Measure a voltage of TP13 on the |

|

| remedy | controller PCB and check thatV is |

|

|

| observed when no paper is stacked, and |

|

|

| that 1 V or less is observed when paper is |

|

|

| stacked. Replace the sensor if the |

|

|

| measured voltage exceeds these ranges. |

| Case2 | Cause | Controller PCB fault |

|

| Check and | If the problem is not solved with a change |

|

| remedy | in the sensor level after the above case 1 |

|

|

| is confirmed, replace the controller PCB. |