9910 specifications

The Singer 9910 is a versatile sewing machine designed to cater to a wide range of sewing needs, making it an excellent choice for both beginners and experienced sewists. One of its standout features is its robust selection of built-in stitches. The machine offers over 100 stitch options, which include utility stitches, decorative stitches, and even stretch stitches, allowing users to tackle various projects from simple alterations to intricate designs with ease.The Singer 9910 also incorporates an automatic needle threader, a feature that saves time and reduces frustration, especially for those who may struggle with threading needles. This convenient technology allows users to quickly set up their machine and get sewing without the hassle of manually threading the needle. Additionally, the machine is equipped with an adjustable stitch length and width, providing further customization for different fabrics and sewing styles.

Another key characteristic of the Singer 9910 is its free arm design, which is perfect for sewing cylindrical items such as sleeves, cuffs, and pant hems. This feature enhances accessibility and accuracy when working on detailed areas. The machine’s drop-in bobbin system allows for easy bobbin insertion and removal, ensuring a smooth sewing experience with fewer thread jams.

Furthermore, the Singer 9910 boasts a powerful motor that ensures consistent stitch quality, even when sewing multiple layers of fabric or thicker materials. Its speed control feature allows users to sew at their preferred pace, making it easier to manage complicated techniques or delicate work. The machine also includes built-in LED lighting, which illuminates the sewing area for improved visibility, allowing users to work comfortably, even in low-light conditions.

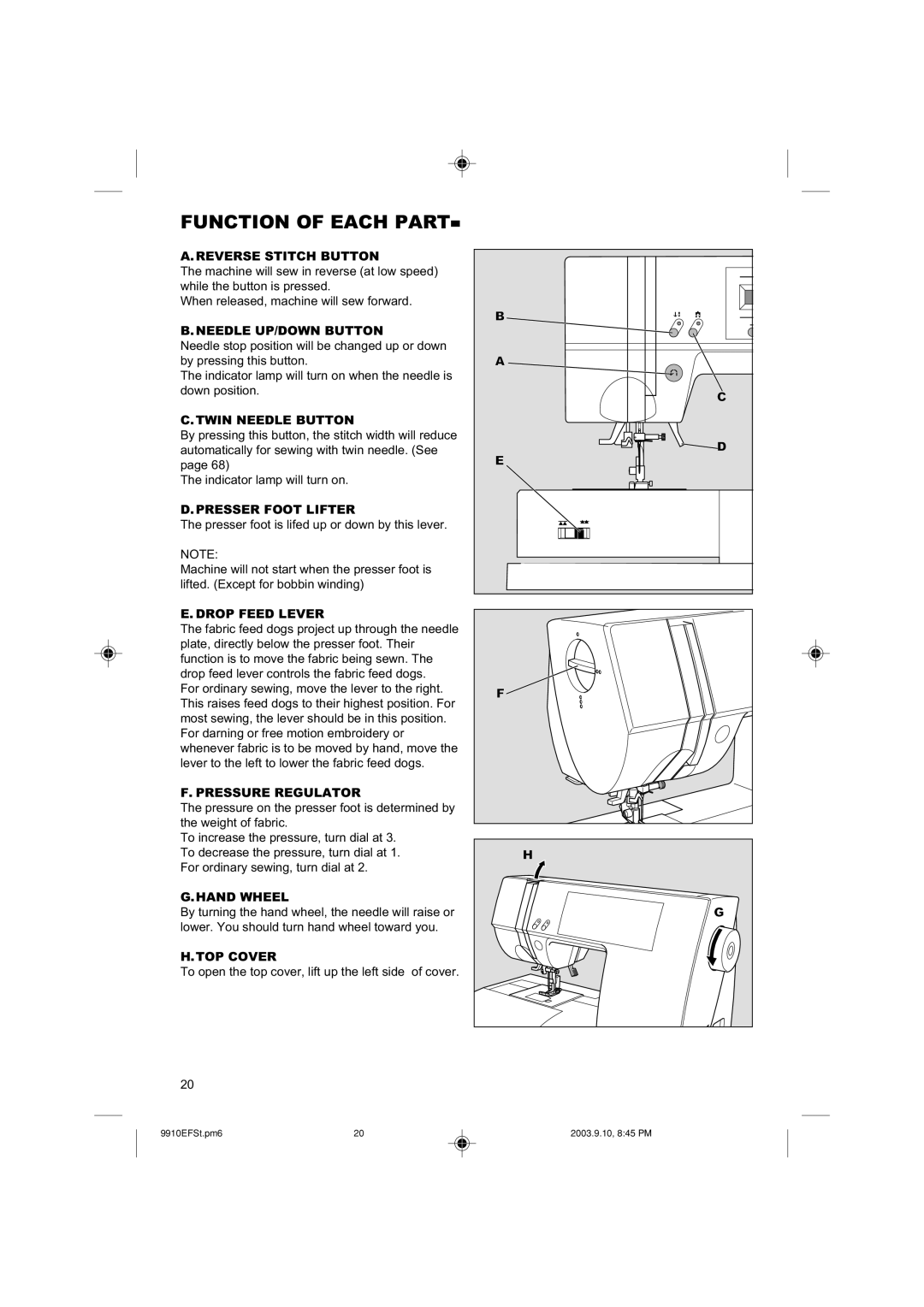

The Singer 9910 is designed with user-friendly controls, including a simple stitch selection dial and a reverse lever for securing stitches. This makes it accessible for beginners while still offering the advanced capabilities that seasoned sewists appreciate. With its combination of functionality, versatility, and cutting-edge technology, the Singer 9910 stands out as a reliable sewing companion for creative individuals looking to bring their sewing projects to life. Whether creating garments, home decor, or crafting, the Singer 9910 delivers performance that meets a wide range of sewing requirements.