Section 3 - MAINTENANCE

3.2.4.CHECK DECK DRIVE BELT

1.The idler and spring provide proper belt tension and require no adjustment. If belt is frayed, slit, severed or belt strands exposed, replace belt before operating mower.

3.3SEVICE - EVERY 25 OPERATING HOURS

3.3.1.CHECK ENGINE

1.Change engine oil. Refer to Section “CHANGE ENGINE OIL”. Refer to engine owner's manual for oil specification.

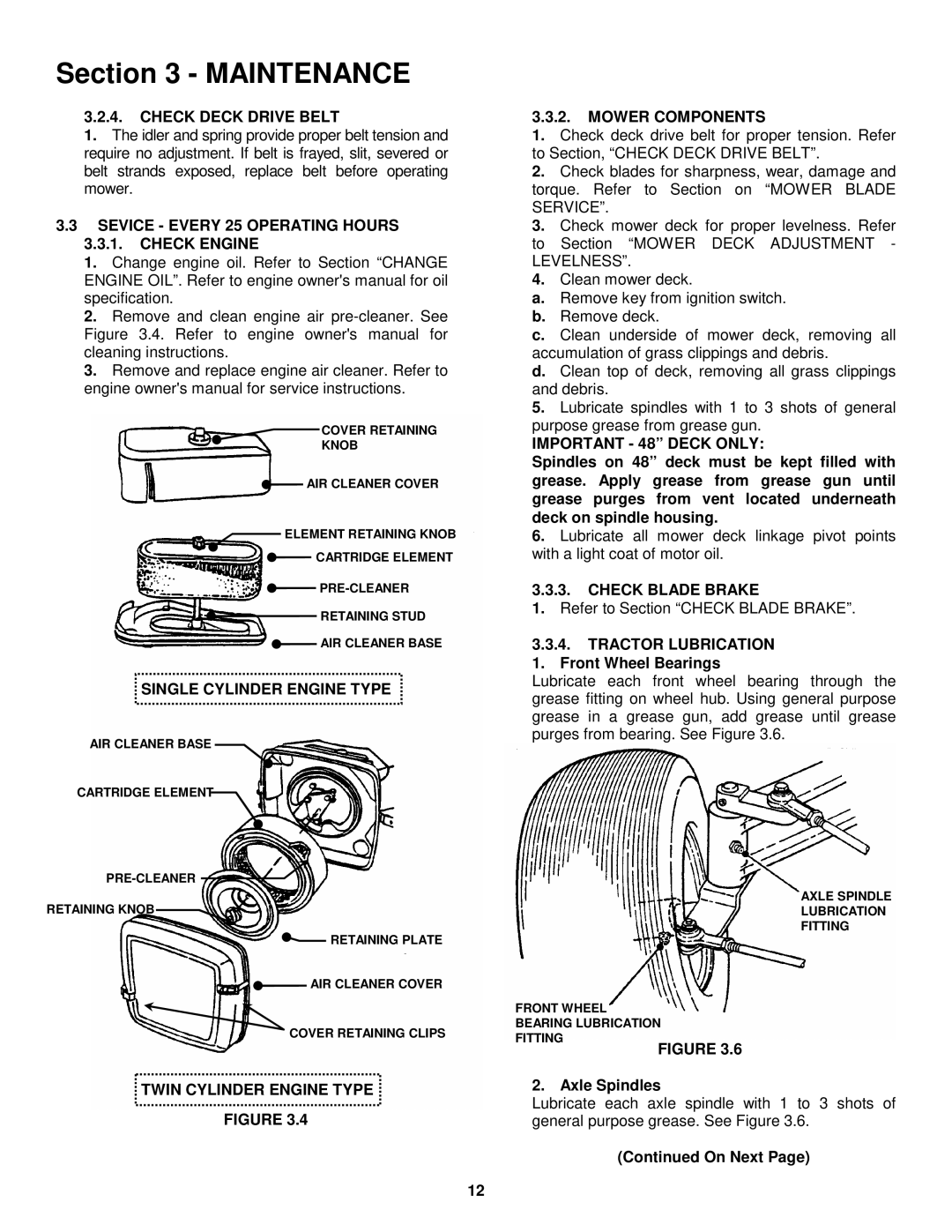

2.Remove and clean engine air

3.Remove and replace engine air cleaner. Refer to engine owner's manual for service instructions.

COVER RETAINING

KNOB

![]() AIR CLEANER COVER

AIR CLEANER COVER

ELEMENT RETAINING KNOB

![]() CARTRIDGE ELEMENT

CARTRIDGE ELEMENT

![]() PRE-CLEANER

PRE-CLEANER

![]() RETAINING STUD

RETAINING STUD

![]() AIR CLEANER BASE

AIR CLEANER BASE

SINGLE CYLINDER ENGINE TYPE

AIR CLEANER BASE

CARTRIDGE ELEMENT

![]()

RETAINING KNOB

![]() RETAINING PLATE

RETAINING PLATE

![]() AIR CLEANER COVER

AIR CLEANER COVER

COVER RETAINING CLIPS

TWIN CYLINDER ENGINE TYPE

FIGURE 3.4

3.3.2.MOWER COMPONENTS

1.Check deck drive belt for proper tension. Refer to Section, “CHECK DECK DRIVE BELT”.

2.Check blades for sharpness, wear, damage and torque. Refer to Section on “MOWER BLADE SERVICE”.

3.Check mower deck for proper levelness. Refer to Section “MOWER DECK ADJUSTMENT -

LEVELNESS”.

4.Clean mower deck.

a.Remove key from ignition switch.

b.Remove deck.

c.Clean underside of mower deck, removing all accumulation of grass clippings and debris.

d.Clean top of deck, removing all grass clippings and debris.

5.Lubricate spindles with 1 to 3 shots of general purpose grease from grease gun.

IMPORTANT - 48” DECK ONLY:

Spindles on 48” deck must be kept filled with grease. Apply grease from grease gun until grease purges from vent located underneath deck on spindle housing.

6.Lubricate all mower deck linkage pivot points with a light coat of motor oil.

3.3.3.CHECK BLADE BRAKE

1.Refer to Section “CHECK BLADE BRAKE”.

3.3.4.TRACTOR LUBRICATION

1. Front Wheel Bearings

Lubricate each front wheel bearing through the grease fitting on wheel hub. Using general purpose grease in a grease gun, add grease until grease purges from bearing. See Figure 3.6.

AXLE SPINDLE

LUBRICATION

FITTING

FRONT WHEEL

BEARING LUBRICATION

FITTING

FIGURE 3.6

2. Axle Spindles

Lubricate each axle spindle with 1 to 3 shots of general purpose grease. See Figure 3.6.

(Continued On Next Page)

12