Marley MD specifications

SPX Cooling Technologies has long been recognized as a leader in the cooling systems industry, and the Marley MD series exemplifies this commitment to innovation and efficiency. The Marley MD line is engineered for performance and versatility, ideal for a wide range of industrial and commercial cooling applications.One of the defining features of the Marley MD is its advanced, modular design. This modular approach allows for easy scalability, enabling users to customize their cooling solution based on specific operational needs. Each unit can be configured to meet varying cooling loads, making the Marley MD suitable for both small and large facilities.

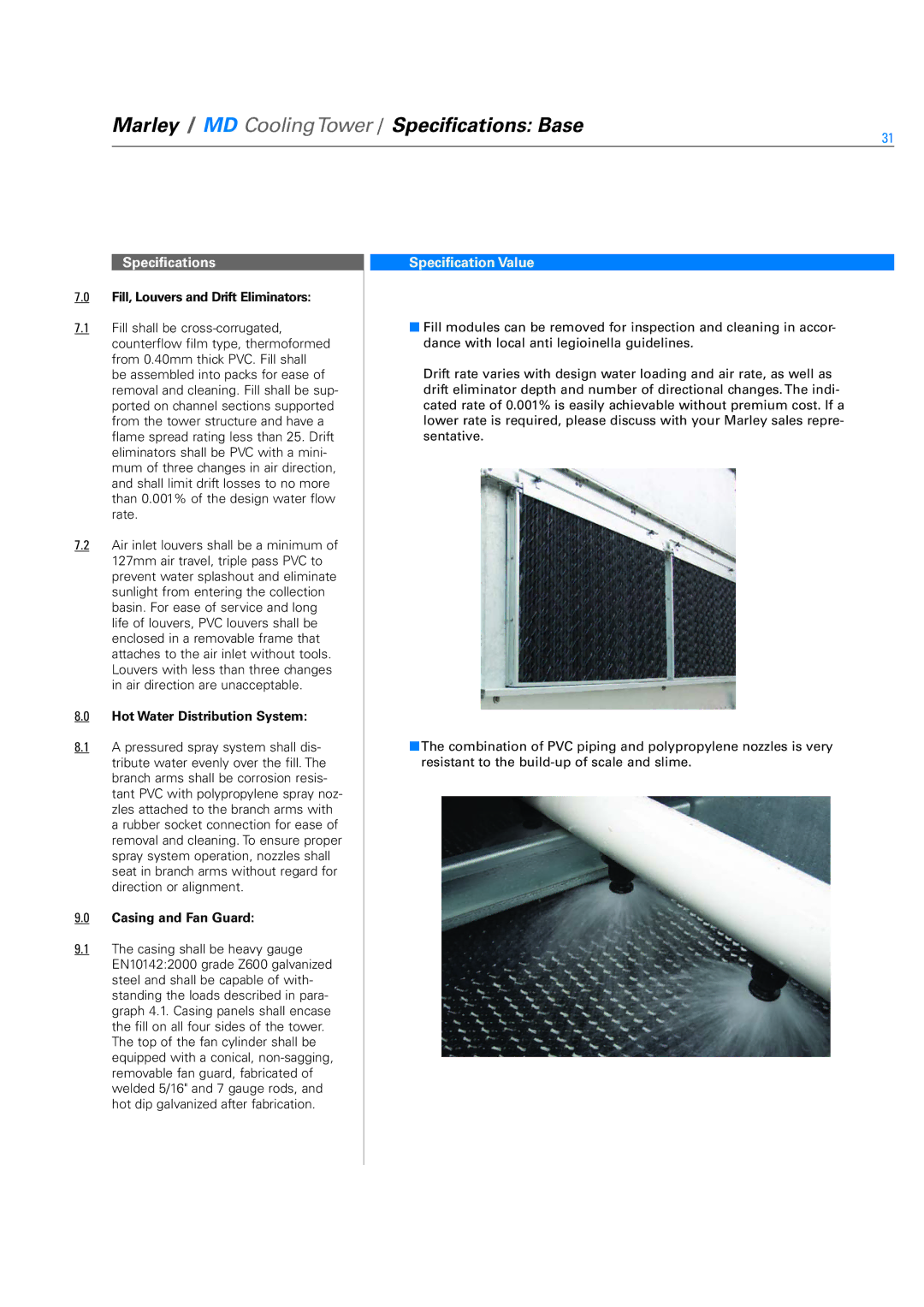

The Marley MD utilizes state-of-the-art materials, promoting durability and longevity. Constructed with corrosion-resistant components, these units are designed to withstand harsh environmental conditions, ensuring reliable operation over extended periods. The casing often features a combination of high-quality steel and advanced coatings that provide protection against the elements, which is especially important for outdoor installation.

Additionally, the Marley MD incorporates innovative technologies such as drift eliminators and splash bars, which significantly enhance water efficiency. These features minimize water loss and reduce the risk of contaminants entering the cooling system, leading to better overall performance. The design is also optimized for low sound levels, making these systems suitable for use in sensitive environments where noise reduction is a priority.

Energy efficiency is a critical characteristic of the Marley MD. It leverages advanced fan technology and airflow management to enhance cooling performance while minimizing energy consumption. By using high-efficiency motors and variable-speed drives, the Marley MD can operate at optimal levels under varying load conditions, resulting in significant energy savings over traditional cooling systems.

Another vital aspect is the ease of maintenance. The Marley MD is designed for straightforward access, allowing for efficient servicing and reducing downtime during maintenance activities. Features like removable panels and accessible components ensure that technicians can perform routine checks and repairs quickly and efficiently.

In conclusion, the Marley MD by SPX Cooling Technologies stands out due to its modular design, durable construction, advanced water management technologies, energy efficiency, and ease of maintenance. These characteristics make it an excellent choice for any facility looking to optimize its cooling operations while ensuring reliable and sustainable performance.