4-3 Basic Setting of the Filling Level in the Conveyor Hopper

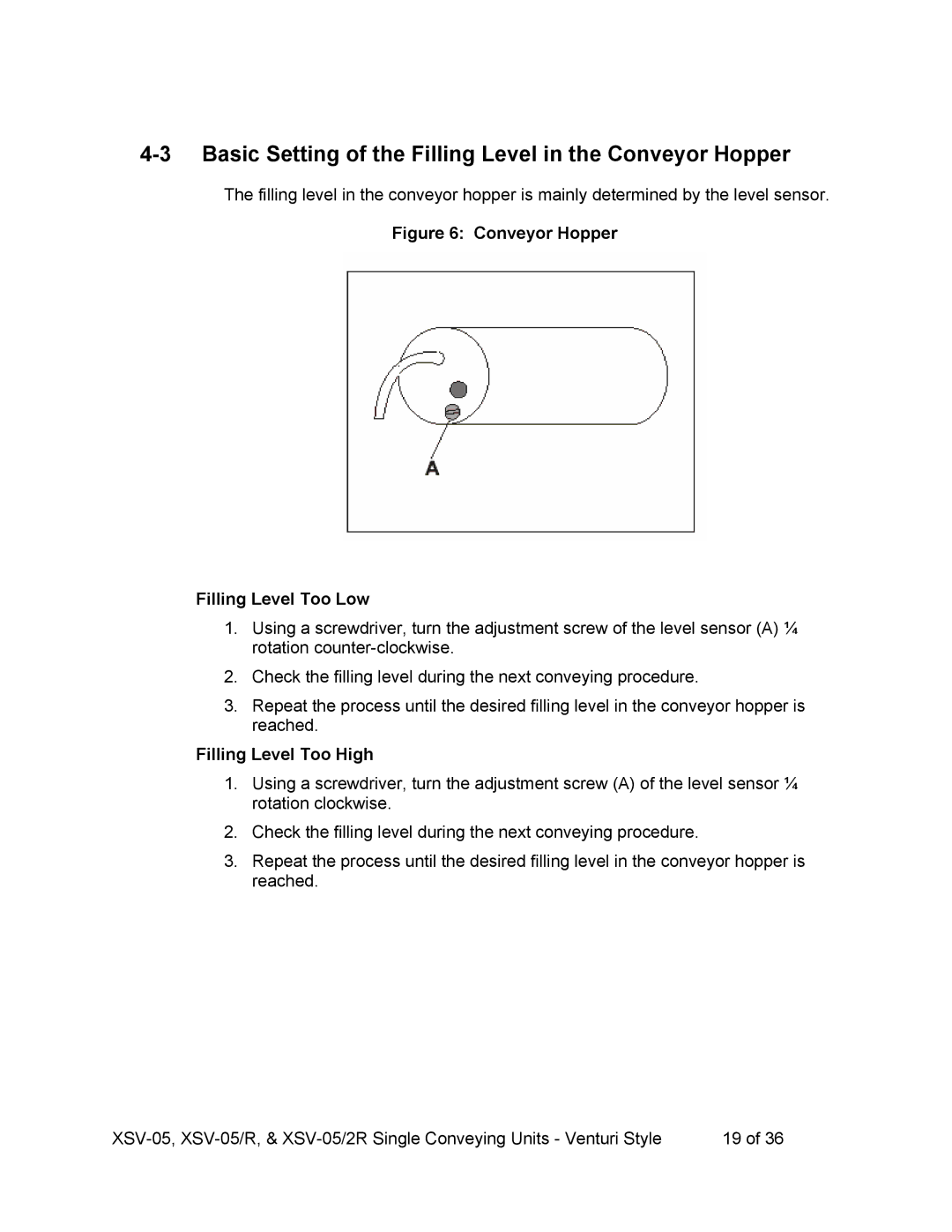

The filling level in the conveyor hopper is mainly determined by the level sensor.

Figure 6: Conveyor Hopper

Filling Level Too Low

1.Using a screwdriver, turn the adjustment screw of the level sensor (A) ¼ rotation

2.Check the filling level during the next conveying procedure.

3.Repeat the process until the desired filling level in the conveyor hopper is reached.

Filling Level Too High

1.Using a screwdriver, turn the adjustment screw (A) of the level sensor ¼ rotation clockwise.

2.Check the filling level during the next conveying procedure.

3.Repeat the process until the desired filling level in the conveyor hopper is reached.

19 of 36 |