Engine Management

Exhaust emissions are controlled by the design of the fundamental engine parameters and components (e.g. carburation, ignition, timing and valve or port timing) without the addition of any major hardware.

Adjusting the Carburetor

General Information

The carburetor comes from the factory with a standard setting.

This setting provides an optimum

Preparations

NShut off the engine.

NCheck the air filter and clean or replace if necessary.

NCheck the spark arresting screen (not in all models,

Different Standard Settings

Different carburetors are installed at the factory. A different standard setting is necessary for each of these carburetors.

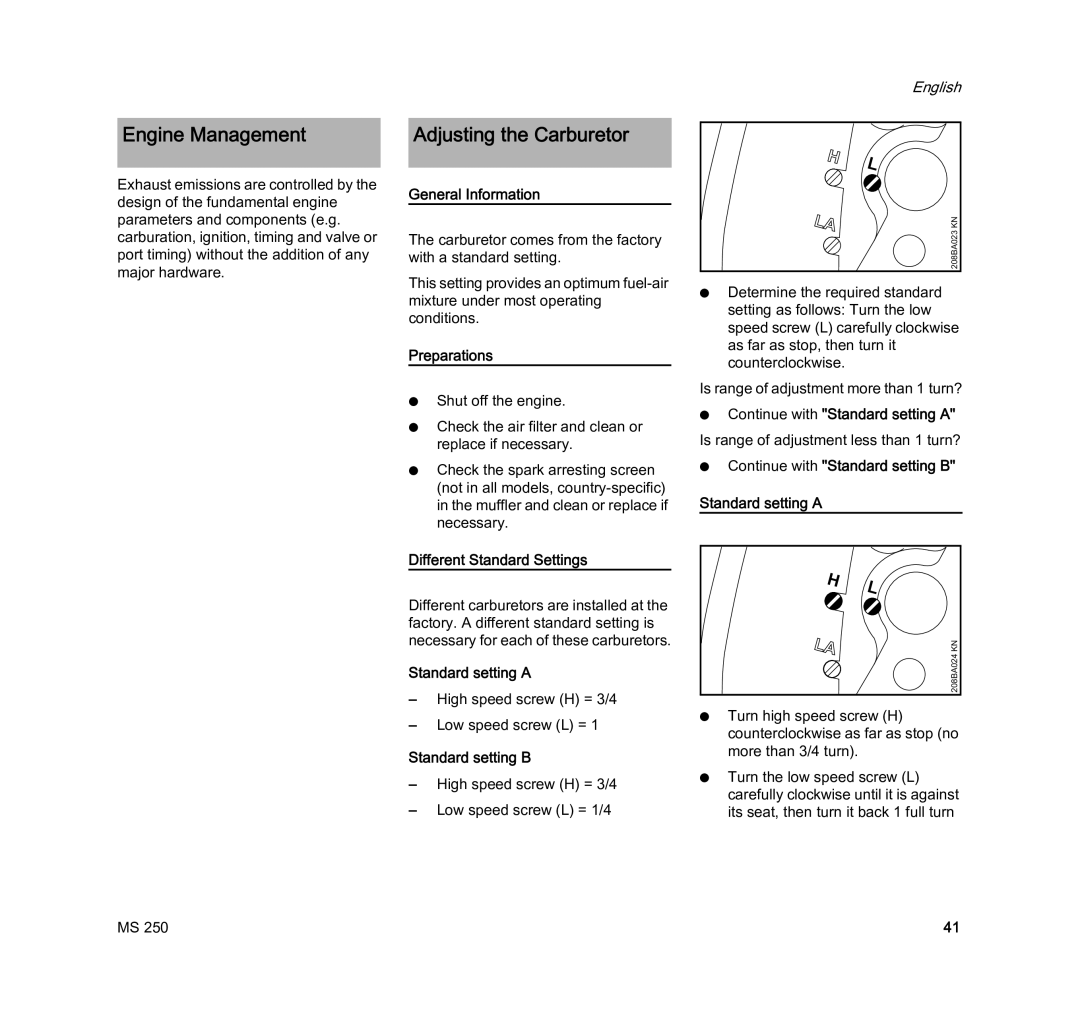

Standard setting A

–High speed screw (H) = 3/4

–Low speed screw (L) = 1

Standard setting B

–High speed screw (H) = 3/4

–Low speed screw (L) = 1/4

English

L

208BA023 KN

NDetermine the required standard setting as follows: Turn the low speed screw (L) carefully clockwise as far as stop, then turn it counterclockwise.

Is range of adjustment more than 1 turn?

NContinue with "Standard setting A" Is range of adjustment less than 1 turn?

N Continue with "Standard setting B"

Standard setting A

H | L |

|

208BA024 KN

NTurn high speed screw (H) counterclockwise as far as stop (no more than 3/4 turn).

NTurn the low speed screw (L) carefully clockwise until it is against its seat, then turn it back 1 full turn

MS 250 | 41 |