In reassembly;

1)Cleancarbonandgumdepositsfromthe valves, seats,portsand valve stemholes.

2)Replace valves, if badly burned, pitted or warped.

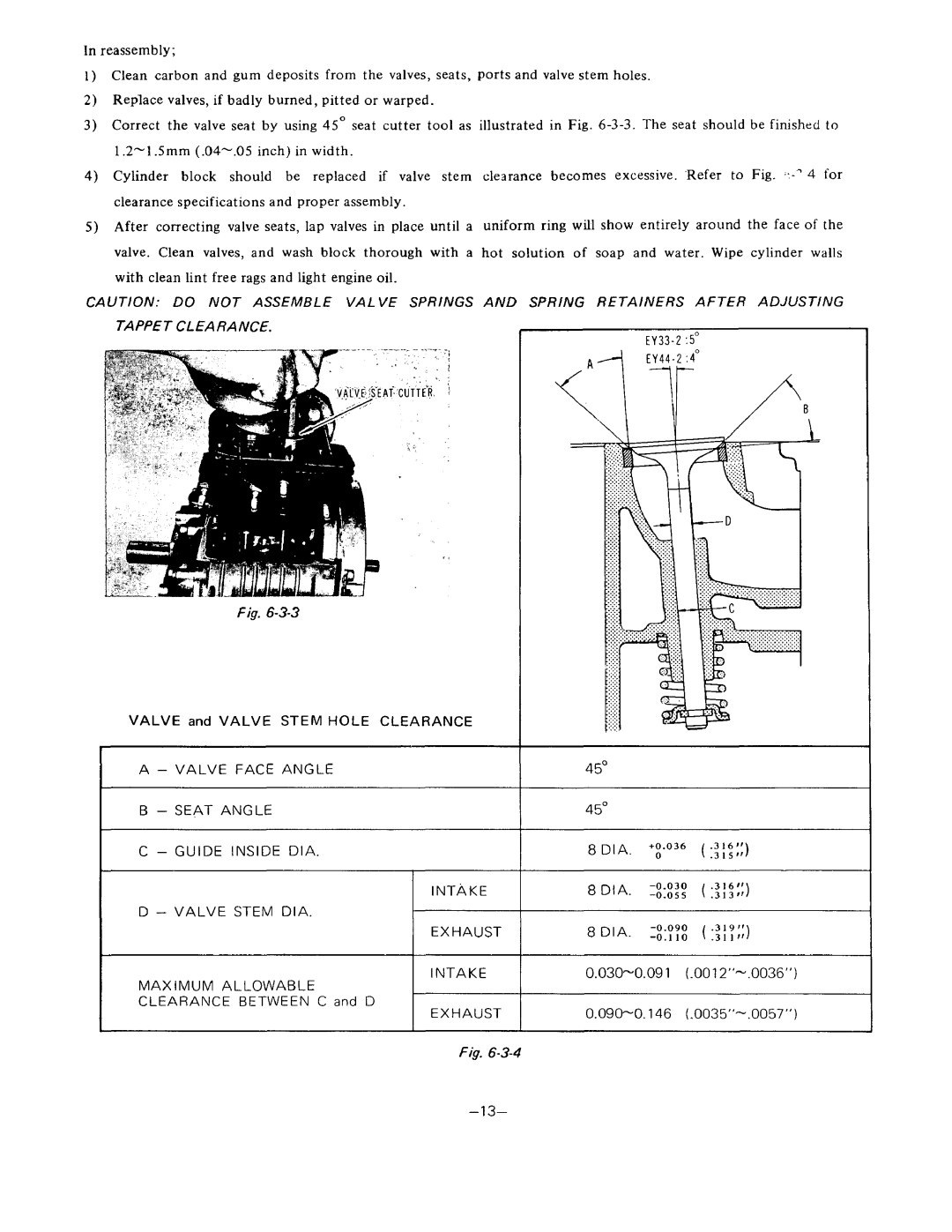

3 ) | Correctthe valve seatby using 45" seatcutter tool asillustratedin | Fig. 6 - 3 - 3 . Theseatshouldbe finished to | ||||

|

|

|

|

|

| |

4) | Cylinderblockshouldbereplaced | if valve | stemclearancebecomesexcessive'Referto. |

| ||

| clearance specifications and proper assembly. |

|

|

|

| |

5 ) Aftercorrecting valve seats, lap valves in place untilauniformring | will showentirelyaroundtheface | of the | ||||

| valve. Clean valves, andwashblockthoroughwith | a hotsolution | of soapandwater. | Wipecylinderwalls | ||

| with clean lint free rags and light engine oil. |

|

|

|

| |

CAUTION: DO NOT ASSEMBLE VALVE SPRINGS ANDSPRINGRETAINERS AFTER ADJUSTING TAPPET CLEARANCE.

Fig.

I I

VALVE and VALVESTEMHOLECLEARANCE

A - VALVE FACE ANGLE | I | 45" |

|

|

| ||

B | - SEAT ANGLE | 45" |

|

|

| ||

I |

|

| I | ||||

C | - GUIDE INSIDE DIA. | 8 DIA. | +:.036 | (::!;::) | |||

|

| ||||||

|

| INTAKE | 8 DIA. | 3168' |

| ||

D - VALVE STEM DIA. |

| ( : 3 1 3 r r ) |

| ||||

|

|

| ( ::fi::) |

| |||

|

| EXHAUST | 8 DIA. | ;:1 |

| ||

MAXIMUMALLOWABLE | INTAKE |

| |||||

|

|

|

|

| |||

CLEARANCE BETWEEN C a n d D | EXHAUST |

| |||||

|

|

| |||||

Fig.