7 . MAGNETO

In Models

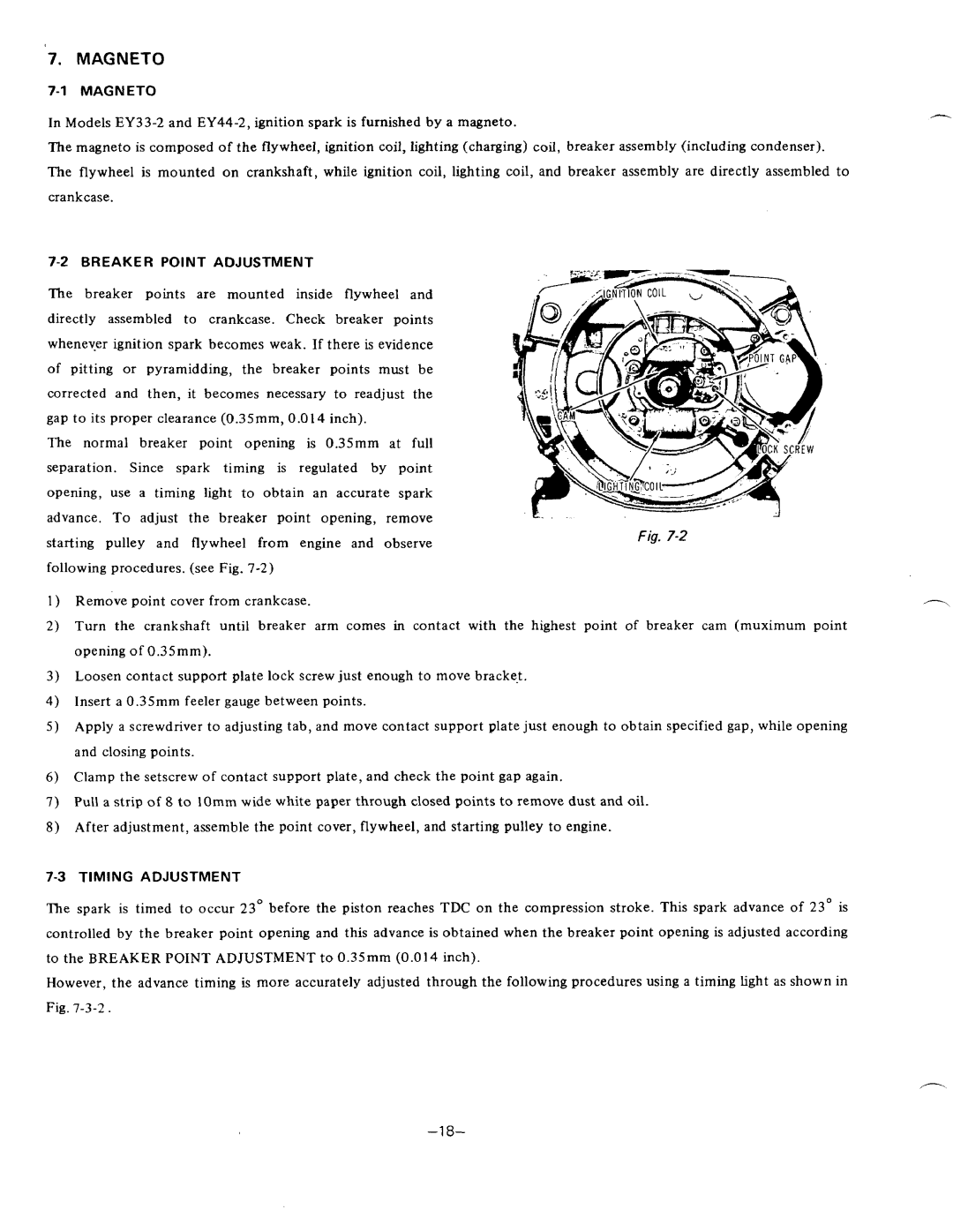

The magneto is composed of the flywheel, ignition coil, lighting (charging) coil, breaker assembly (including condenser).

Theflywheel is mounted on crankshaft,whileignitioncoil,lightingcoil,andbreakerassemblyaredirectlyassembledto

crankcase.

directlyassembled tocrankcaseCheckbreakerpoints.

whenever ignition spark becomes weak. If there is evidence

of pittingorpyramidding,thebreakerpointsmustbe |

| |||

correctedandthen, | it becomesnecessarytoreadjustthe |

| ||

gap to its proper clearance (0.35mm, 0.014 inch). |

| |||

Thenormalbreakerpointopening | is 0.35mmat | full | ||

separationSincesparktiming. | is regulatedbypoint |

| ||

opening, | use atiminglight | toobtainanaccuratespark |

| |

advance. | To adjustthebreakerpointopening,remove |

| ||

startingpulleyandflywheelfromengineandobserve following procedures. (see Fig.

Remove point cover from crankcase.

Turnthecrankshaftuntilbreakerarmcomesin contactwiththehighestpoint of breakercam(muximumpoint

opening of 0.35mm).

Loosen contact support plate lock screw just enough to move bracket.

Insert a 0.35mm feelergauge between points.

Apply a screwdriver to adjusting tab, and move contact support plate just enoughto obtain specified gap, while opening and closing points.

Clamp the setscrew of contact support plate, and check the point gap again.

Pull a strip of 8 t o lOmm wide white paper through closed points to remove dust and oil.

After adjustment, assemble the point cover, flywheel, and starting pulley to engine.

Thespark is timed tooccur23"beforethepistonreaches TDC onthecompressionstroke.Thissparkadvance of 23' is controlled by the breaker point opening and this advance is obtained when the breaker point opening is adjusted according to the BREAKER POINT ADJUSTMENT to 0.35mm (0.014 inch).

However, the advance timing is more accurately adjusted through the following procedures using a timing light as shown in Fig. 7 - 3 - 2 .