4 — OPERATOR SERVICE

WEEKLY SERVICE CHECKS

Perform the following service checks at least once each week:

Check Battery electrolyte level.

If battery charge is low, add enough water to bring the electrolyte level to the top of the plates.

If batteries are fully charged, raise electrolyte level to full mark in each cell.

Inspect all electrical wiring.

Check for cuts, loose terminals, broken wires, chaffing and corrosion.

Repair all damage, remove corrosion and seal exposed connections.

Check transport hitch components for damage.

Inspect Boom lift for missing, loose or damaged hardware.

Repair or replace as necessary.

MONTHLY SERVICE CHECKS

Perform the following service checks at least once each month:

Clean all battery terminals.

Check battery for loose connections or damaged wires.

Verify proper operation of manual lowering valves and hand pump

Refer to Section 3 for manual boom operating procedures.

Lubricate all compartment hinges and latches, slew ring and mating gear.

Use NLGI Grade 2

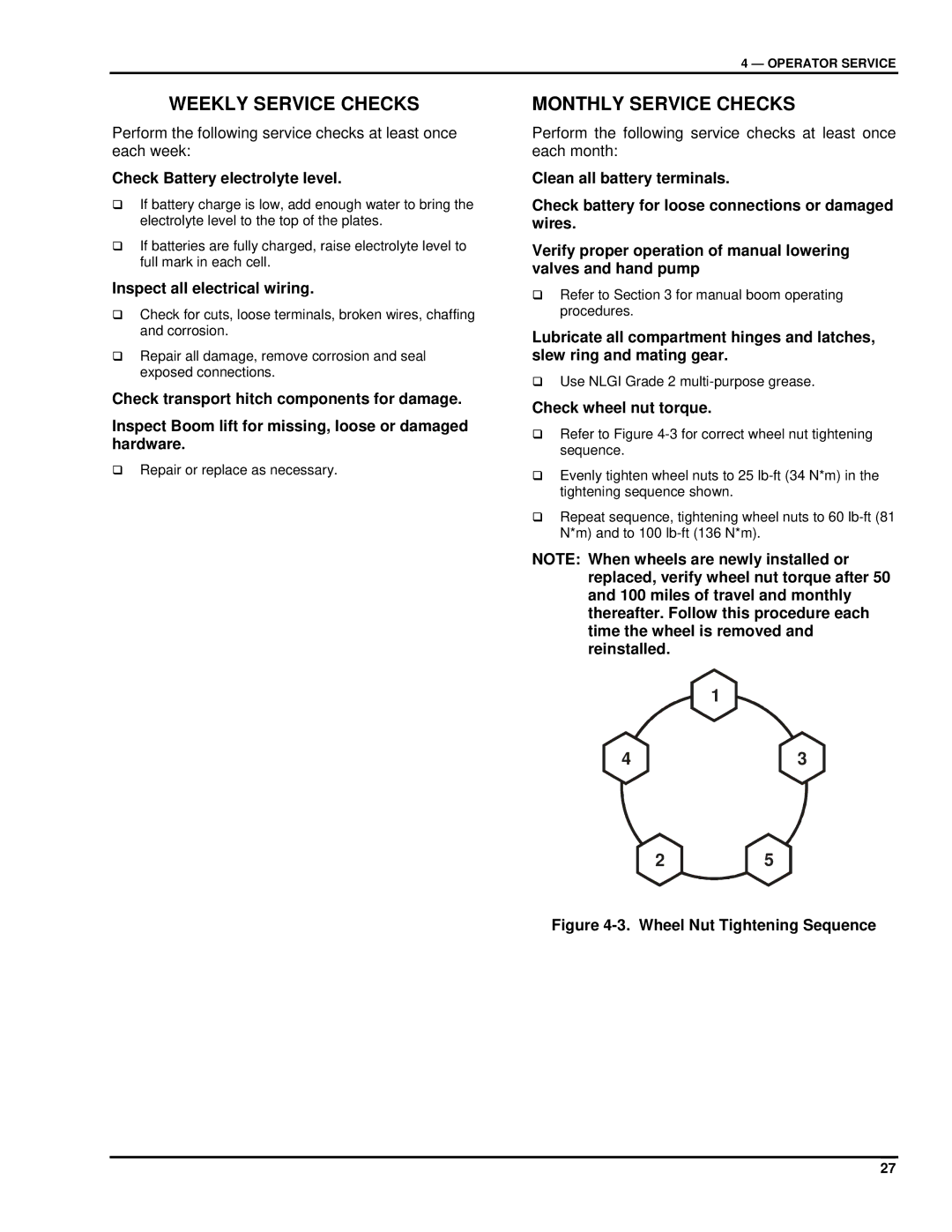

Check wheel nut torque.

Refer to Figure

Evenly tighten wheel nuts to 25

Repeat sequence, tightening wheel nuts to 60

NOTE: When wheels are newly installed or replaced, verify wheel nut torque after 50 and 100 miles of travel and monthly thereafter. Follow this procedure each time the wheel is removed and reinstalled.

1

43

2 5

Figure 4-3. Wheel Nut Tightening Sequence

27