GTS-820A Series

Page

General Handling Precautions

Storage in the case

Maintenance for driving parts

Rotating the instrument and telescope

Display for Safe Use

Safety Cautions

Exceptions from Responsibility

User

Labels

Laser Safety

Symbol marks while the laser is emitting

Mode Laser class

Contents

Correction for Refraction and Earth Curvature

APPENDIX-1

Standard Set Composition

Nomenclature and Functions

Nomenclature and Functions

Nomenclature

Nomenclature and Functions

Display

Laser is off

Operating Key

Laser is emitting

Waiting Laser is emitting Searching Laser is emitting

Display Soft Function

Function Key Soft Key

SET

Meas

Mode

Mean

Screen

Star key *key mode

2003 143040

2003-10-10

+00000

OFF

Set audio mode

512KB 315KByte 1882KByte

Reticle illumination OFF/Low/Middle/High

Operation

Meaning of Tracking Indicator on or Flashing

Tracking Indicator

Rotating by H/V Shuttle and H/V Jog

Auto Power Off

Data Output

Rotating Method

RC-2RII

Using together with RC-2II Remote Control System

Turn-round function

On / OFF

Using connecting with Personal Computer PC

Commands Action of GTS-820A series

Preparation for Measurement

Power Connection

Unnecessary if on-board Ni-MH battery BT-56Q is used

Preparation for Measurement

Reference Leveling and Centering the Instrument

Setting Instrument Up For Measurement

2003-10-10

Power Switch Key on

Password option

Choosing the first mode when turning on the instrument

Battery Level Indicator

Main Menu Icons

Parameters Setting Modes

Vertical and Horizontal Angle Tilt Correction

Compensation of Systematic Error of Instrument

Operating procedure Option Display

Resume Mode ON/OFF

How to Enter Numerals and Alphabet Letters

Pressing F1OFF key or F2ON key, select the resume mode

Memory Card

How to insert a memory card

How to extract a memory card

Prism constant value 30mm

Inclination of Prism and Measuring Error

Prism constant value 0mm

Prism type-2 Normal prism

Distance error is

Angle error is

Example

Instrument searches the prism and tracks Automatically

Press the F1 key. The mode will be Automatic tracking mode

Automatic Tracking / Automatic Collimation

Automatic Tracking

Waiting status

Normal Status Mode

Automatic tracking

Tracking

PPM

Automatic Collimation

NEZ 0SET Hold P1↓

Range of Laser for Auto-tracking and Auto-collimating

Search Patterns

Setting Parameters for Auto-Tracking

Setting Items

Items Selecting item Contents

Prediction operating time

Wait Time

Tracking Speed

Reflector type

Operating procedure Option

How to set the parameters

Measuring Horizontal Angle Right and Vertical Angle

Standard Measurement Mode

Reference How to Collimate

Angle Measurement

Measuring from the Required Horizontal Angle

Switching Horizontal Angle Right/Left

Setting by Holding the Angle

Vertical Angle Percent Grade% Mode

Input the horizontal angle to be rotated,

Press the F1TURN key

Press the F3 key

For example 93 Angle

Distance Measurement Continuous Measurement

Setting of the Atmospheric Correction

Setting of the Correction for Prism Constant

Distance Measurement

2Measuring Method

Distance Measurement Single/N-times Measurement

Meas Mode NEZ P1↓

Fine / Coarse Measuring Mode

Stake Out S-O

Display value = Measured distance -Standard Preset distance

Press F5SET key

Setting Coordinate Values of Occupied Point

Operating procedure Operation Display

Press F3NEZ key

PSM PPM Turn HT

ENT Standard Measurement Mode

Exitbs

Setting of the Instrument Height / Prism Height

Collimate target B Press F3NEZ key.*3 Measuring starts

PSM PPM Meas Mode VH

Execution of Coordinate Measuring

PPM Meas Mode VH SD

Measurement will be started

Mode will automatically return to the distance

Slope distance mode V, HR,SD

Coordinate mode Z, HR

Standard Measurement Mode

Line Store Offset REM EXT.LINK MLM More

Program Modes

Program Modes

F6MORE key

Entering the instrument and backsight coordinate values

Setting a Direction Angle for Backsight Orientation

Retaining a Coordinate STORE- NEZ

YES no

SET OK? YES

Store REM MLM More

With prism height h input Example h=1.5m

Remote Elevation measurement REM

Horizontal distance HD between

2Without prism height input

Measset REM

Press F2NO key

Exit HD

SET REM

Exit HD REM

Press F1A-B, A-C key

Missing Line Measurement MLM

Press F4MLM key

Exit HD MLM

Measset MLM

1To return to main menu, pressF1EXIT and F5YES key

Line Measurement Line

Meas SET Line

Line PT a

Meas SET Line PT B

Line PT B Meas SET

Exit Next

Line Point

Exit SET Line

Line Offset EXT.LINK More

Distance measurement mode of the offset measurement

Offset measurement Offset

Outputting the Measurement Data

Press F1ANGLE Offset key

Angle Offset

To get to the next page of programs

Press F2OFFSET key

Next NEZ

Measht Angle Offset

Previous offset value screen will appear

Distance Offset Measurement

Offset Measurement

Press F2DIST. Offset key

Exitbs DIST. Offset Meas

Plane will be shown

Plane Offset Measurement

Press F3PLANE Offset key

Measurement screen of three points on a

Measht Plane Offset

Column Offset Measurement

SET Column Offset

Starting compatible communication program of AP-L1A

Setting for the communication

1Setting communication course

External Link

CABLE/RADIO MODEM/RC SET ↑ ↓ Exit

2Setting Parameters of Cable RS-232C

Parameters

Speed

3Setting Parameters of RC

Channel SET Exit

4Setting Parameters for Radio Modem

REC-A

REC-B

SET Exit REC Type REC-A

Channel setting display is provided Only for certain market

Carrying out Communication

Channel

View Internal Memory and Card Memory Status

Memory Manage Modes

Rename a File

Operating procedure Operation Display Proceed Chapter

Refer to .9 How to Enter Numerals and Alphabet Letters

Protect a File

Copy a File

Deleting a File

Initializing Memory

Communication Modes

Setting of Protocol

Data File Out

Data File

Parameters for Measurement and Display

Parameters Setting Mode

Parameter Setting Options

Menu Selecting Item Contents

NEZ / ENZ

Meter /FEET

OFF / MEM.ON

Serial port

Setting parameters for RS232C

Setting parameter for RC

Parameters for communication

Crlf

ETX

Setting Parameters

Establishing a Password

Password Option

Exit Change On OFF

Turning OFF the Password

Turning OFF the Password Option

OFF Exit Change

Changing a Password

Changing the Password

Checking and Adjusting of Instrument Constant

Check and Adjustment

Direction confirmation Do not move V direction

Checking the Optical Axis

Check and Adjustment

Pointers on the Adjustment

Checking/Adjusting the Theodolite Functions

Check

Checking /Adjusting the Plate Level

Checking /Adjusting the Circular Level

Adjustment

Adjustment of the Vertical Cross-hair

Collimation of the Instrument

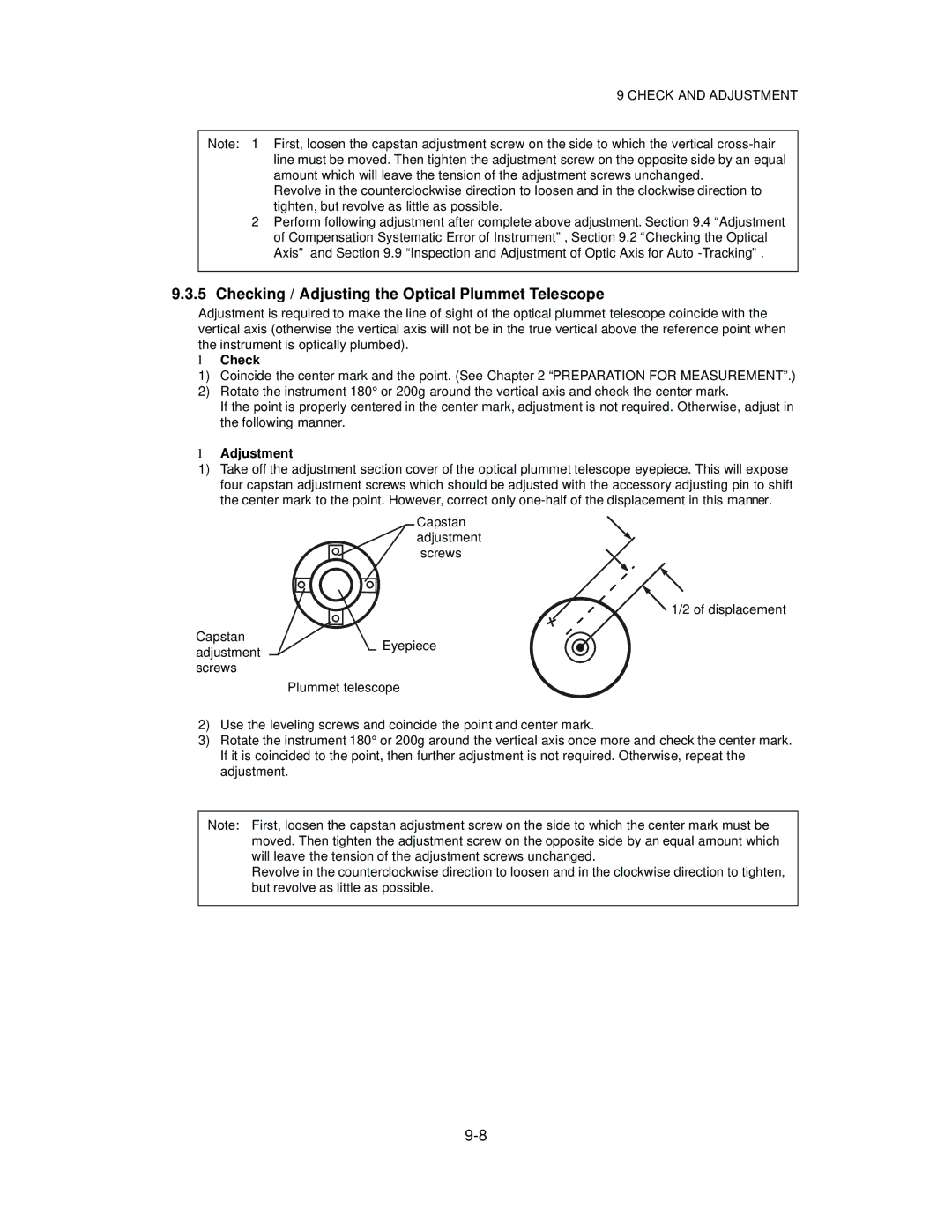

Checking / Adjusting the Optical Plummet Telescope

Adjustment of Compensation Systematic Error of Instrument

Skipset Face LEVEL±10

Skipset

Skipset Face

Press F6OFF key

Press F2 key

Correction values are displayed

Exit OFF

How to adjust the date and time

Input value and press ENT key Value

How to Set the Instrument Constant Value

Press F4 Instrument constant key

Press F5 YES key

Beam will be emitted

Reference Frequency Checking Mode

Press the F6 ↓ key to get to next page on

Press the F1 key

Turn Meas

Inspection and Adjustment of Optic Axis for Auto -Tracking

Normal position Centers of prism

Adj Tracking Axis Wait Set OK?

Setting the Prism Constant Value

Setting the Prism Constant Value

How to Set Temperature and Pressure Value Directly

Setting Atmospheric Correction

Setting of Atmospheric Correction Value

Setting Atmospheric Correction

11-2

How to Set the Atmospheric Correction Value Directly

Atmospheric Correction Chart For your reference

11-4

11-5

Correction for Refraction and Earth Curvature

Correction for Refraction and Earth Curvature

Distance Calculation Formula

Rechargeable Battery BT-56Q

Power Source and Charging

13-2

Attachment

DETACH/ATTACH of Tribrach

DETACH/ATTACH of Tribrach

Detachment

Case of External battery Pack

Battery System

Case of Rechargeable Battery BT-56Q

Prism System

Prism System

Precautions

Precautions

Over

Error Displays

Error Displays

Special Accessories

Gadget case, Model

Cigarette battery charger BC-9 for BT-3Q

Battery charger BC-6 for BT-3L

Prism unit case, Model

Aluminum extension leg tripod, Type E

Power cord PC-6 For BT-3L, AC-6

Large capacity battery pack BT-3L

Power cord PC-5

Manual Driving

Specifications

Specifications

Automatic Tracking / Collimating

Electronic Angle Measurement

Distance measurement

Atmospheric conditions

Condition

Display and keyboard

Tilt Correction

Others

Computer unit

Battery Charger BC-27BR / BC-27CR

Appendix

Appendix

Dual Axis Compensation

APPENDIX-2

Storage

Precaution when Charging or Storing Batteries

Recharging

Discharge

APPENDIX-4

Embedded Products

END User License Agreement

EMC Notice

Page

GTS-820A series