Section 5: Maintenance

WARNING Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to come

![]() to a complete stop, disconnect spark plug wire and move wire away from spark plug. Remove ignition key, if so equipped.

to a complete stop, disconnect spark plug wire and move wire away from spark plug. Remove ignition key, if so equipped.

Failure to follow these instructions can result in serious personal injury or property damage.

IMPORTANT: Do not allow oil or grease to contact the pulleys, drive belt or reverse disc. This can cause the belt or disc to slip on the pulleys.

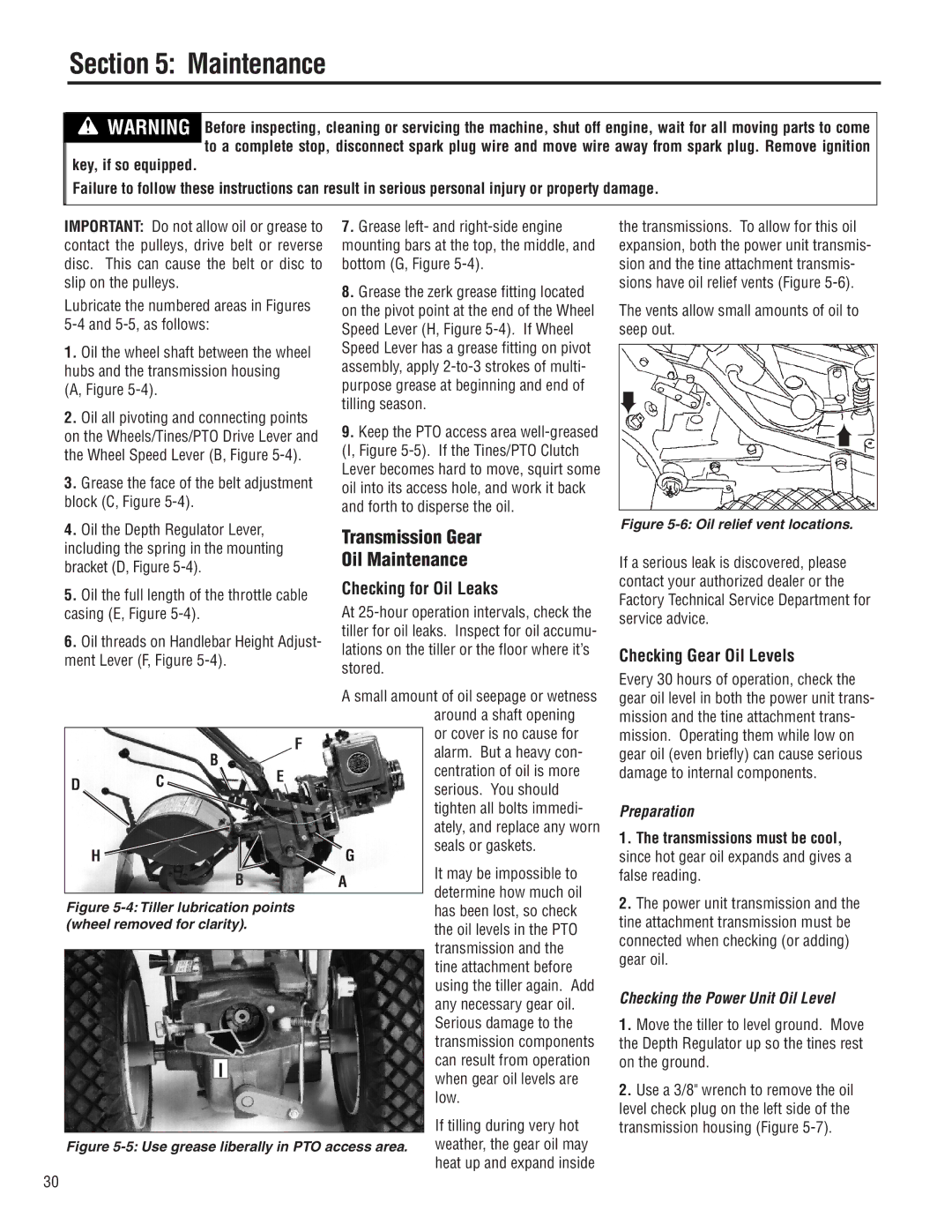

Lubricate the numbered areas in Figures

1.Oil the wheel shaft between the wheel hubs and the transmission housing (A, Figure

2.Oil all pivoting and connecting points on the Wheels/Tines/PTO Drive Lever and the Wheel Speed Lever (B, Figure

3.Grease the face of the belt adjustment block (C, Figure

4.Oil the Depth Regulator Lever, including the spring in the mounting bracket (D, Figure

7.Grease left- and

8.Grease the zerk grease fitting located on the pivot point at the end of the Wheel Speed Lever (H, Figure

9.Keep the PTO access area

Transmission Gear

Oil Maintenance

the transmissions. To allow for this oil expansion, both the power unit transmis- sion and the tine attachment transmis- sions have oil relief vents (Figure

The vents allow small amounts of oil to seep out.

➨

➨

Figure 5-6: Oil relief vent locations.

If a serious leak is discovered, please

5. | Oil the full length of the throttle cable | Checking for Oil Leaks | |

At | |||

casing (E, Figure | |||

6. | Oil threads on Handlebar Height Adjust- | tiller for oil leaks. Inspect for oil accumu- | |

lations on the tiller or the floor where it’s | |||

ment Lever (F, Figure | |||

stored. | |||

|

| ||

|

| A small amount of oil seepage or wetness | |

|

|

|

|

|

|

| around a shaft opening |

|

|

|

|

|

|

| or cover is no cause for |

|

|

|

|

|

| F | |

| B |

| alarm. But a heavy con- | ||||

|

|

| |||||

| E |

| centration of oil is more | ||||

D | C |

| |||||

| serious. You should | ||||||

|

| ||||||

|

|

|

|

|

|

| tighten all bolts immedi- |

|

|

|

|

|

|

| ately, and replace any worn |

| H |

|

| G | seals or gaskets. | ||

|

|

| It may be impossible to | ||||

|

|

|

|

|

|

| |

|

|

| B |

| A | ||

|

|

|

| determine how much oil | |||

Figure |

| ||||||

| has been lost, so check | ||||||

(wheel removed for clarity). |

|

| the oil levels in the PTO | ||||

|

|

|

|

|

|

| transmission and the |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| tine attachment before |

|

|

|

|

|

|

| using the tiller again. Add |

|

|

|

|

|

|

| any necessary gear oil. |

|

|

|

|

|

|

| Serious damage to the |

|

|

|

|

|

|

| transmission components |

|

|

|

|

|

|

| can result from operation |

|

| I |

|

|

|

| |

|

|

|

|

|

| when gear oil levels are | |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| low. |

|

|

|

|

|

|

| If tilling during very hot |

Figure | weather, the gear oil may | ||||||

|

|

|

|

|

|

| heat up and expand inside |

contact your authorized dealer or the Factory Technical Service Department for service advice.

Checking Gear Oil Levels

Every 30 hours of operation, check the gear oil level in both the power unit trans- mission and the tine attachment trans- mission. Operating them while low on gear oil (even briefly) can cause serious damage to internal components.

Preparation

1.The transmissions must be cool, since hot gear oil expands and gives a false reading.

2.The power unit transmission and the tine attachment transmission must be connected when checking (or adding) gear oil.

Checking the Power Unit Oil Level

1.Move the tiller to level ground. Move the Depth Regulator up so the tines rest on the ground.

2.Use a 3/8" wrench to remove the oil level check plug on the left side of the

transmission housing (Figure

30