Section 5: Maintenance

WARNING Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to come

![]() to a complete stop, disconnect spark plug wire and move wire away from spark plug. Remove ignition key, if so equipped.

to a complete stop, disconnect spark plug wire and move wire away from spark plug. Remove ignition key, if so equipped.

Failure to follow these instructions can result in serious personal injury or property damage.

Adjusting Reverse Drive:

1.Place Wheels/Tines/PTO Drive Lever in FORWARD position.

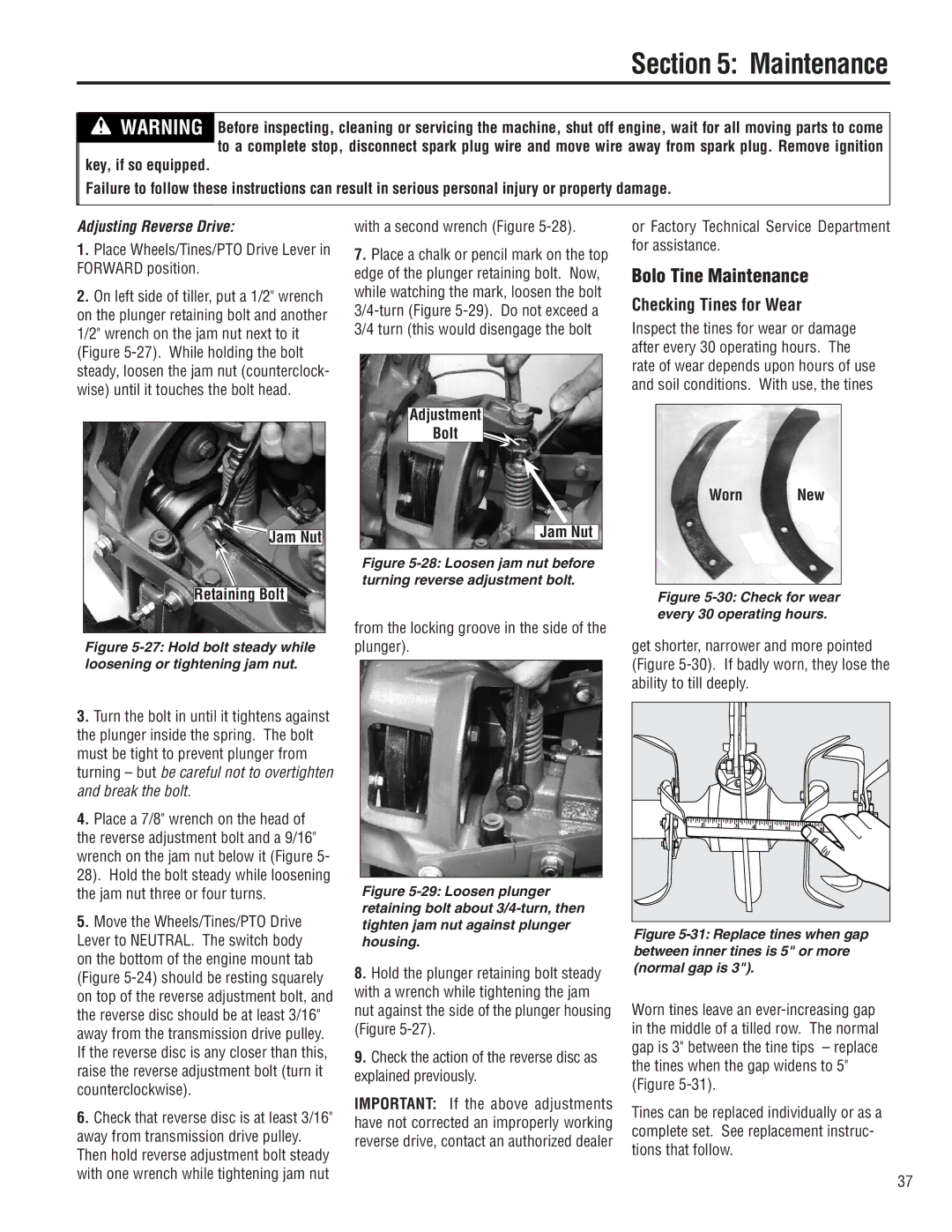

2.On left side of tiller, put a 1/2" wrench on the plunger retaining bolt and another 1/2" wrench on the jam nut next to it (Figure

Jam Nut

Jam Nut

Retaining Bolt

Figure 5-27: Hold bolt steady while loosening or tightening jam nut.

3.Turn the bolt in until it tightens against the plunger inside the spring. The bolt must be tight to prevent plunger from turning – but be careful not to overtighten and break the bolt.

4.Place a 7/8" wrench on the head of

the reverse adjustment bolt and a 9/16" wrench on the jam nut below it (Figure 5- 28). Hold the bolt steady while loosening the jam nut three or four turns.

5.Move the Wheels/Tines/PTO Drive Lever to NEUTRAL. The switch body on the bottom of the engine mount tab (Figure

6.Check that reverse disc is at least 3/16" away from transmission drive pulley. Then hold reverse adjustment bolt steady with one wrench while tightening jam nut

with a second wrench (Figure 5-28).

7.Place a chalk or pencil mark on the top edge of the plunger retaining bolt. Now, while watching the mark, loosen the bolt

Adjustment

Bolt

Jam Nut

Figure 5-28: Loosen jam nut before turning reverse adjustment bolt.

from the locking groove in the side of the plunger).

Figure 5-29: Loosen plunger retaining bolt about 3/4-turn, then tighten jam nut against plunger housing.

8.Hold the plunger retaining bolt steady with a wrench while tightening the jam nut against the side of the plunger housing (Figure

9.Check the action of the reverse disc as explained previously.

IMPORTANT: If the above adjustments have not corrected an improperly working reverse drive, contact an authorized dealer

or Factory Technical Service Department for assistance.

Bolo Tine Maintenance

Checking Tines for Wear

Inspect the tines for wear or damage after every 30 operating hours. The rate of wear depends upon hours of use and soil conditions. With use, the tines

Worn New

Figure 5-30: Check for wear every 30 operating hours.

get shorter, narrower and more pointed (Figure

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|

|

|

|

|

|

Figure 5-31: Replace tines when gap between inner tines is 5" or more (normal gap is 3").

Worn tines leave an

(Figure

Tines can be replaced individually or as a complete set. See replacement instruc- tions that follow.

37