CDV Series Direct Vent Gas Fireplace

Example: |

|

|

|

|

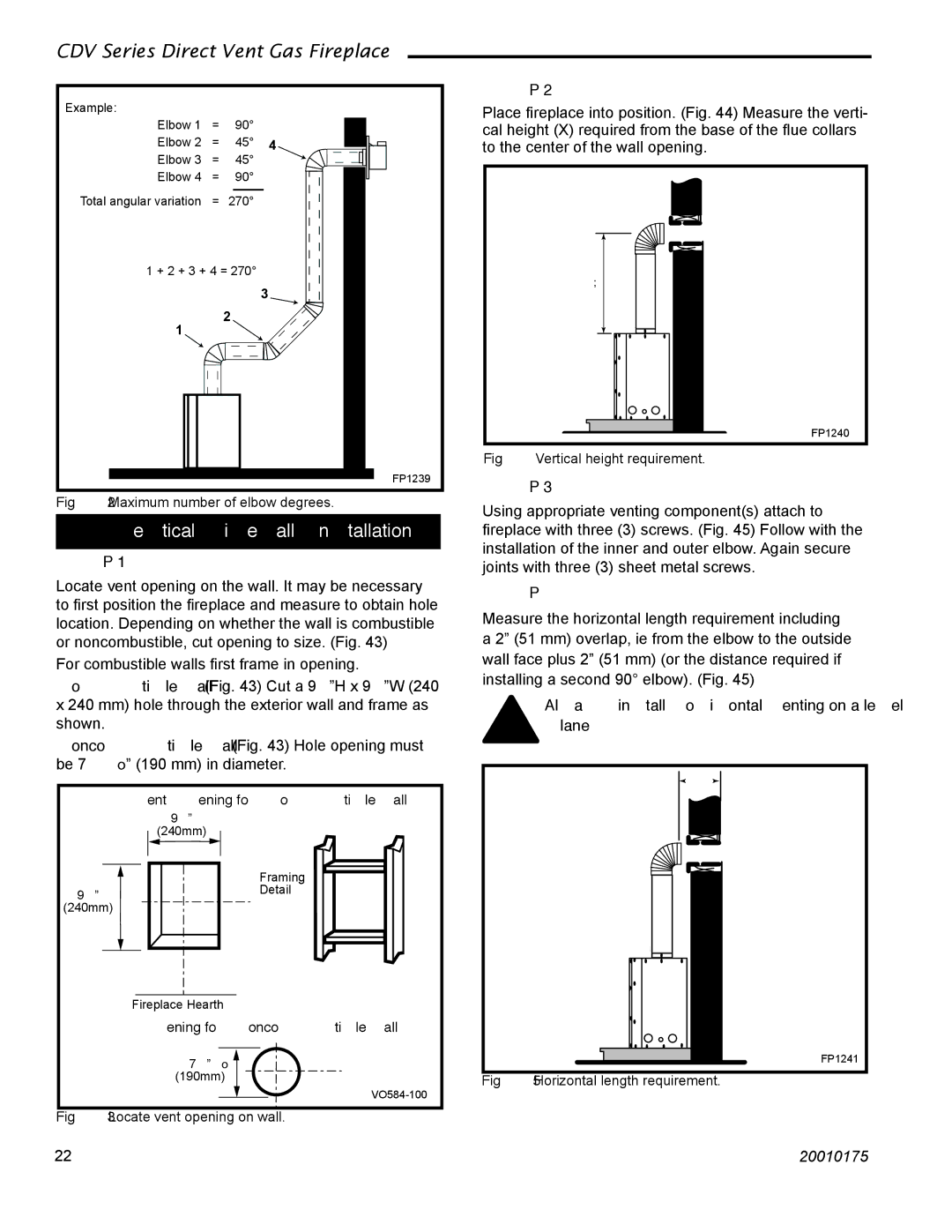

Elbow 1 | = | 90° |

| |

Elbow 2 | = | 45° 4 | ||

Elbow 3 | = | 45° |

| |

Elbow 4 | = | 90° |

| |

|

|

|

|

|

Total angular variation | = | 270° |

| |

1 + 2 + 3 + 4 = 270°

STEP 2

Place fireplace into position. (Fig. 44) Measure the verti- cal height (X) required from the base of the flue collars to the center of the wall opening.

1

3

2

FP1239

X

FP1240

Fig. 44 Vertical height requirement.

STEP 3

Fig. 42 Maximum number of elbow degrees.

Vertical Sidewall Installations

STEP 1

Locate vent opening on the wall. It may be necessary to first position the fireplace and measure to obtain hole location. Depending on whether the wall is combustible or noncombustible, cut opening to size. (Fig. 43)

For combustible walls first frame in opening.

Combustible Walls: (Fig. 43) Cut a 9³⁄₈”H x 9³⁄₈”W (240 x 240 mm) hole through the exterior wall and frame as shown.

Noncombustible Walls: (Fig. 43) Hole opening must be 7¹⁄₂” (190 mm) in diameter.

Vent Opening for Combustible Wall

9³⁄₈”

(240mm)

Framing

9³⁄₈”Detail (240mm)

Fireplace Hearth

Opening for Noncombustible Wall

7¹⁄₂”

(190mm)

Fig. 43 Locate vent opening on wall.

Using appropriate venting component(s) attach to fireplace with three (3) screws. (Fig. 45) Follow with the installation of the inner and outer elbow. Again secure joints with three (3) sheet metal screws.

STEP 4

Measure the horizontal length requirement including a 2” (51 mm) overlap, ie from the elbow to the outside wall face plus 2” (51 mm) (or the distance required if installing a second 90° elbow). (Fig. 45)

Always install horizontal venting on a level plane.

X

FP1241

Fig. 45 Horizontal length requirement.

22 | 20010175 |