VERTICAL SIDEWALL INSTALLATION

STEP 1

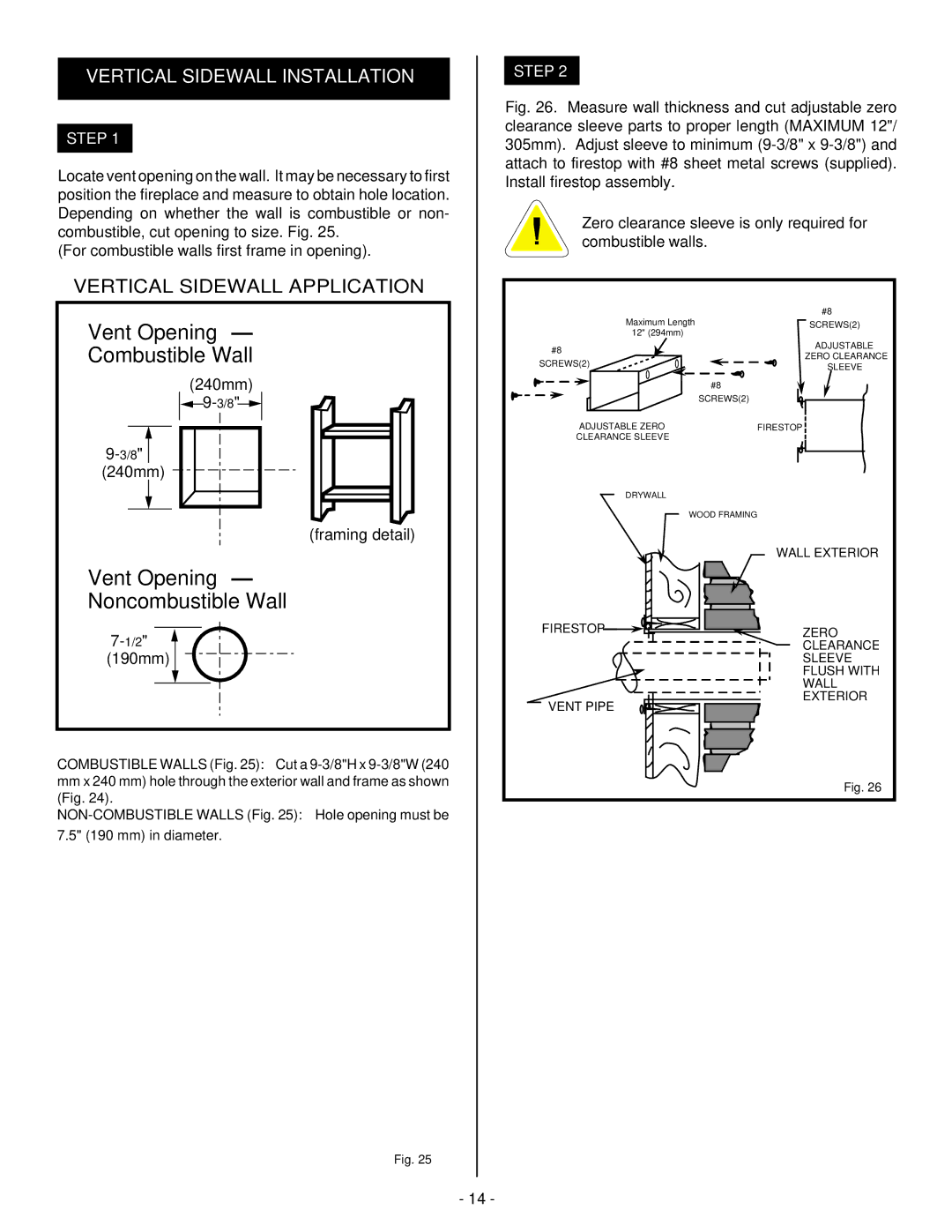

Locate vent opening on the wall. It may be necessary to first position the fireplace and measure to obtain hole location. Depending on whether the wall is combustible or non- combustible, cut opening to size. Fig. 25.

(For combustible walls first frame in opening).

VERTICAL SIDEWALL APPLICATION

Vent Opening —

Combustible Wall

(240mm) ![]()

![]() 9-3/8"

9-3/8"![]()

(framing detail)

Vent Opening —

Noncombustible Wall

7-1/2"  (190mm)

(190mm)

COMBUSTIBLE WALLS (Fig. 25): Cut a

mmx 240 mm) hole through the exterior wall and frame as shown (Fig. 24).

Fig. 25

STEP 2

Fig. 26. Measure wall thickness and cut adjustable zero clearance sleeve parts to proper length (MAXIMUM 12"/ 305mm). Adjust sleeve to minimum (9-3/8" x 9-3/8") and attach to firestop with #8 sheet metal screws (supplied). Install firestop assembly.

Zero clearance sleeve is only required for combustible walls.

| #8 | |

Maximum Length | SCREWS(2) | |

12" (294mm) | ||

| ||

#8 | ADJUSTABLE | |

ZERO CLEARANCE | ||

SCREWS(2) | ||

SLEEVE | ||

| ||

#8 |

| |

SCREWS(2) |

| |

ADJUSTABLE ZERO | FIRESTOP | |

CLEARANCE SLEEVE |

| |

DRYWALL |

| |

WOOD FRAMING |

| |

| WALL EXTERIOR | |

FIRESTOP | ZERO | |

| ||

| CLEARANCE | |

| SLEEVE | |

| FLUSH WITH | |

| WALL | |

VENT PIPE | EXTERIOR | |

| ||

| Fig. 26 |

- 14 -