Step 7. Stipthe flashingover the PipeSection(s) protrudingthrough the roof. Secure the base of the Flashing to the roof with roofing nails. Insure the roofing material overlapsthe top edge of the Flashingas shown in Fig. 14. Verifythat you have at least the minimum' clearance to combustiblesat the roofline.

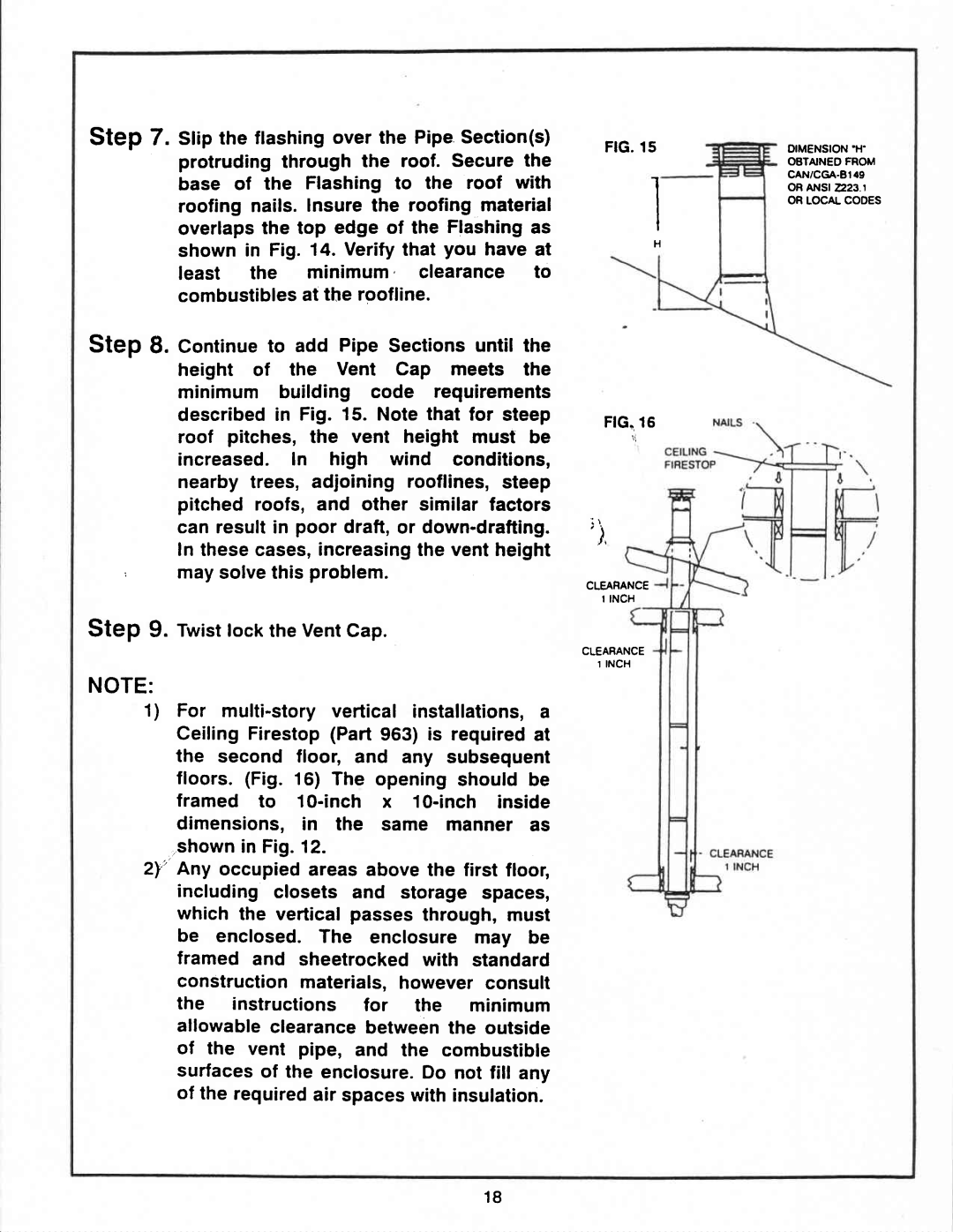

Step8. Continueto add Pipe Sectionsuntil the height of the Vent Cap meets the minimum building code requirements describedin Fig. 15. Note that for steep roof pitches, the vent height must be increased. In high wind conditions, nearby trees, adioining rooflines, steep pitched roofs, and other similar factors can resultin poor draft, or

Step9. TwistlocktheVentCap.

NOTE:

1)For

.shownin Fig.12.

2l' Any occupiedareas abovethe first floor, including closets and storage spaces, which the vertical passes through, must be enclosed. The enclosure may be framed and sheetrockedwith standard constructionmaterials,however consult the instructions for the minimum allowableclearancebetweenthe outside of the vent pipe, and the combustible surfacesof the enclosure.Do not fill any of the requiredair spaceswithinsulation.

FtG.15DIM€NSION'H'

OETAINEOFROM

H

FlG . ,16

:\

, )

y ' r

CLE^RANCE

I INCH

CLEARANCE

1 INCH

1 8