Maintenance Instructions

cleaning/

checking/servicing

GHS Exhaust Screen

Refer to Cleaning the GHS Exhaust Screen in Op erating Instructions.

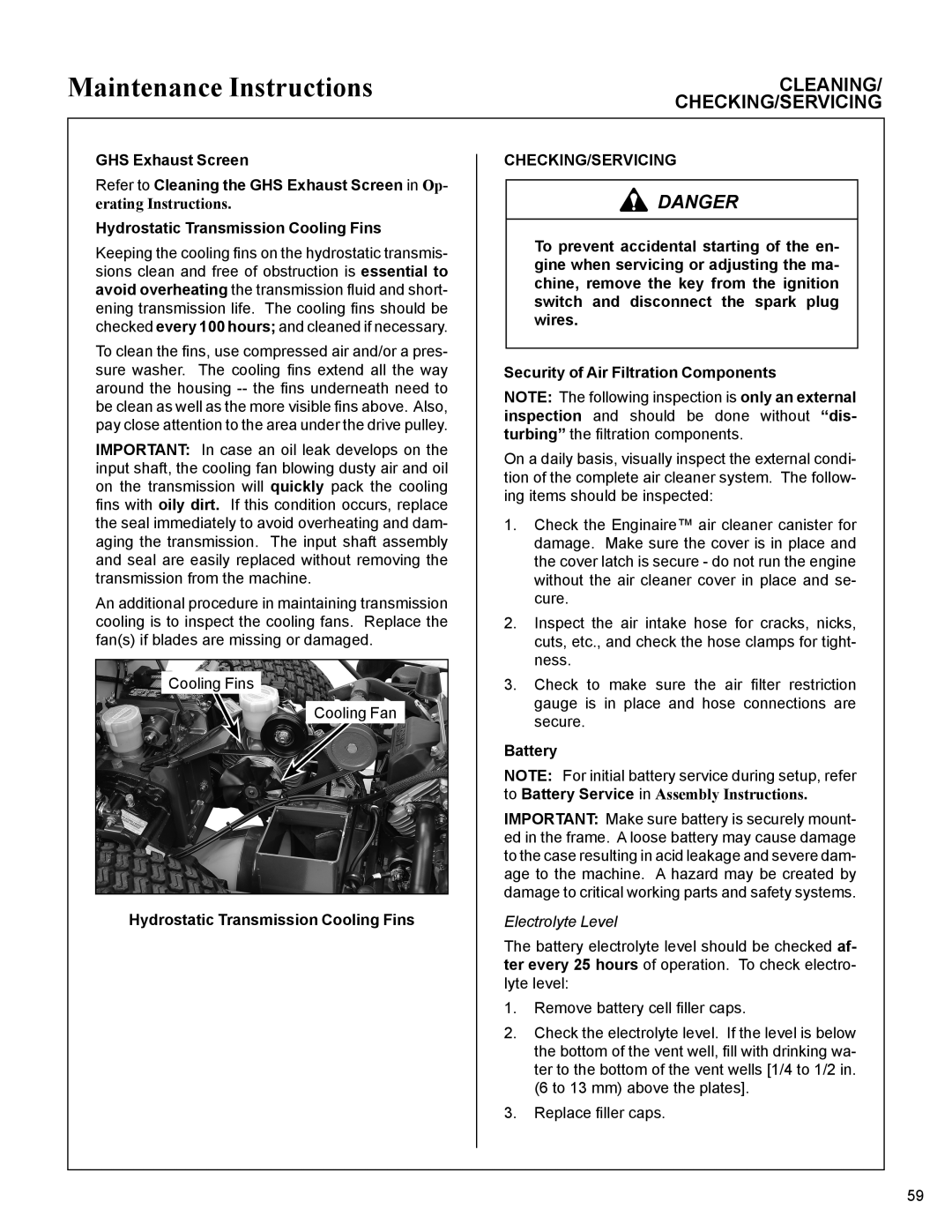

Hydrostatic Transmission Cooling Fins

Keeping the cooling fins on the hydrostatic transmis sions clean and free of obstruction is essential to avoid overheating the transmission fluid and short ening transmission life. The cooling fins should be checked every 100 hours; and cleaned if necessary.

To clean the fins, use compressed air and/or a pres sure washer. The cooling fins extend all the way around the housing

IMPORTANT: In case an oil leak develops on the input shaft, the cooling fan blowing dusty air and oil on the transmission will quickly pack the cooling fins with oily dirt. If this condition occurs, replace the seal immediately to avoid overheating and dam aging the transmission. The input shaft assembly and seal are easily replaced without removing the transmission from the machine.

An additional procedure in maintaining transmission cooling is to inspect the cooling fans. Replace the fan(s) if blades are missing or damaged.

Cooling Fins

Cooling Fan

Hydrostatic Transmission Cooling Fins

CHECKING/SERVICING

![]() DAnger

DAnger

To prevent accidental starting of the en gine when servicing or adjusting the ma chine, remove the key from the ignition switch and disconnect the spark plug wires.

Security of Air Filtration Components

NOTE: The following inspection is only an external inspection and should be done without “dis turbing” the filtration components.

On a daily basis, visually inspect the external condi tion of the complete air cleaner system. The follow ing items should be inspected:

1.Check the Enginaire™ air cleaner canister for damage. Make sure the cover is in place and the cover latch is secure - do not run the engine without the air cleaner cover in place and se- cure.

2.Inspect the air intake hose for cracks, nicks, cuts, etc., and check the hose clamps for tight ness.

3.Check to make sure the air filter restriction gauge is in place and hose connections are secure.

Battery

NOTE: For initial battery service during setup, refer to Battery Service in Assembly Instructions.

IMPORTANT: Make sure battery is securely mount ed in the frame. A loose battery may cause damage to the case resulting in acid leakage and severe dam age to the machine. A hazard may be created by damage to critical working parts and safety systems.

Electrolyte Level

The battery electrolyte level should be checked af ter every 25 hours of operation. To check electro lyte level:

1.Remove battery cell filler caps.

2.Check the electrolyte level. If the level is below the bottom of the vent well, fill with drinking wa ter to the bottom of the vent wells [1/4 to 1/2 in. (6 to 13 mm) above the plates].

3.Replace filler caps.

59