Rear back hang | Locking Pliers | |

assembly | ||

| ||

Perforated |

| |

angle |

| |

| Shaft |

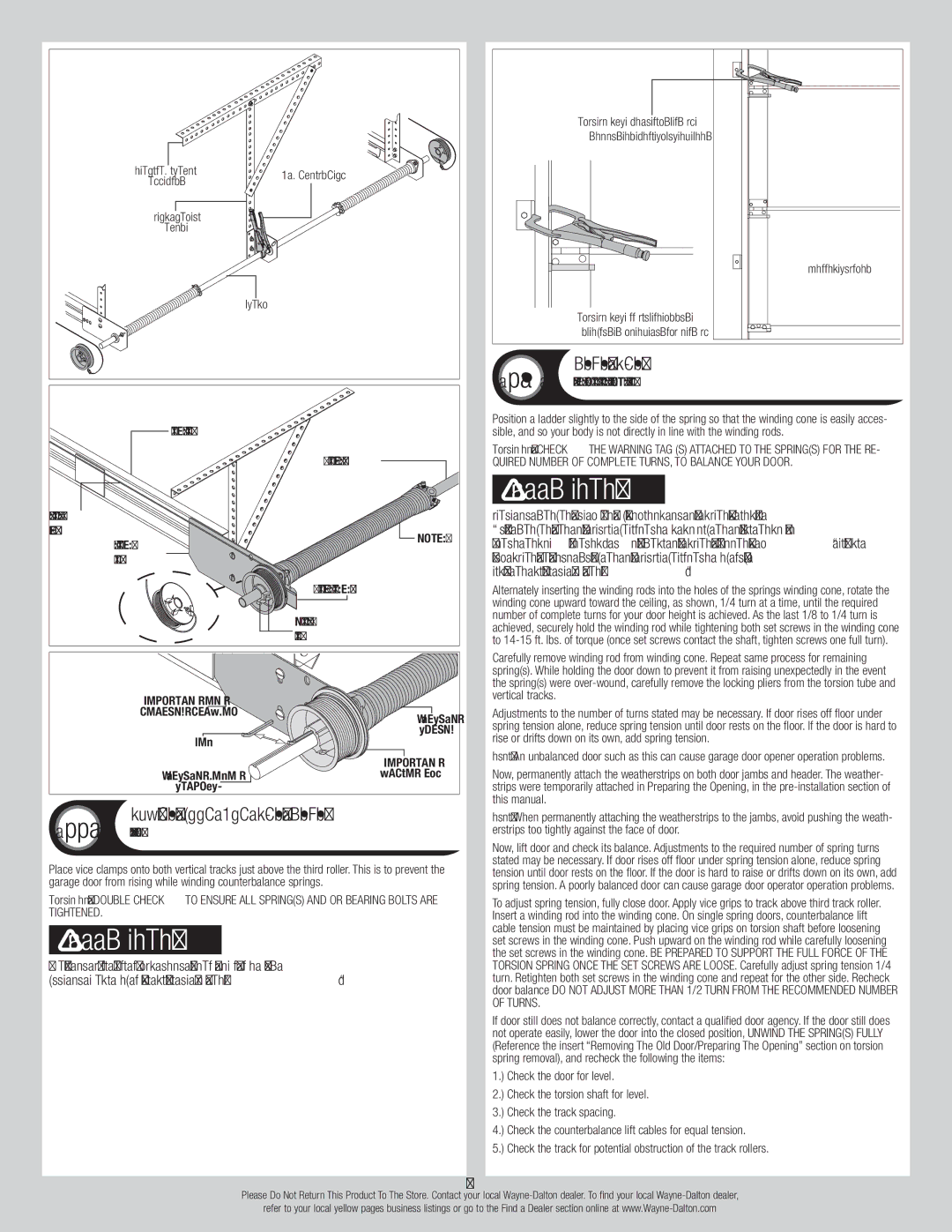

Vice clamps above third track roller on both sides of door

Vice clamps attached to inner and outer rail of vertical track

Bottom section

| Horizontal track | |

| Torsion shaft | |

Counterbalance |

| |

lift cable | Spring | |

End bearing | ||

| ||

bracket |

| |

| Torsion warning tag | |

| Set screws on | |

| cable drum |

Left hand end |

|

bearing bracket | Torsion |

| |

Key | spring |

| |

| Left hand |

Torsion keyed | cable drum |

shaft(s) |

|

22 | Securing Door for Spring Winding |

Tools: Vice Clamps |

Place vice clamps onto both vertical tracks just above the third roller. This is to prevent the garage door from rising while winding counterbalance springs.

IMPORTANT: Double check to ensure all spring(s) and or bearing bolts are tightened.

![]() WARNING

WARNING

Failure to place vice clamps onto vertical track can allow door to raise and cause severe or fatal injury.

23 | Winding Springs |

Tools: Step Ladder, Approved winding bars, 3/8” Wrench |

Position a ladder slightly to the side of the spring so that the winding cone is easily acces- sible, and so your body is not directly in line with the winding rods.

IMPORTANT: Check the warning tag (s) attached to the spring(s) for the re- quired number of complete turns, to balance your door.

![]() WARNING

WARNING

Prior to winding or making adjustments to the springs, ensure you’re winding in the proper direction as stated in these Instal- lation Instructions. Otherwise the spring fittings may release from spring if not wound in the proper direction and could result in severe or fatal injury.

Alternately inserting the winding rods into the holes of the springs winding cone, rotate the winding cone upward toward the ceiling, as shown, 1/4 turn at a time, until the required number of complete turns for your door height is achieved. As the last 1/8 to 1/4 turn is achieved, securely hold the winding rod while tightening both set screws in the winding cone to

Carefully remove winding rod from winding cone. Repeat same process for remaining spring(s). While holding the door down to prevent it from raising unexpectedly in the event the spring(s) were

Adjustments to the number of turns stated may be necessary. If door rises off floor under spring tension alone, reduce spring tension until door rests on the floor. If the door is hard to rise or drifts down on its own, add spring tension.

NOTE: An unbalanced door such as this can cause garage door opener operation problems.

Now, permanently attach the weatherstrips on both door jambs and header. The weather- strips were temporarily attached in Preparing the Opening, in the

NOTE: When permanently attaching the weatherstrips to the jambs, avoid pushing the weath- erstrips too tightly against the face of door.

Now, lift door and check its balance. Adjustments to the required number of spring turns stated may be necessary. If door rises off floor under spring tension alone, reduce spring tension until door rests on the floor. If the door is hard to raise or drifts down on its own, add spring tension. A poorly balanced door can cause garage door operator operation problems.

To adjust spring tension, fully close door. Apply vice grips to track above third track roller. Insert a winding rod into the winding cone. On single spring doors, counterbalance lift cable tension must be maintained by placing vice grips on torsion shaft before loosening set screws in the winding cone. Push upward on the winding rod while carefully loosening the set screws in the winding cone. BE PREPARED TO SUPPORT THE FULL FORCE OF THE TORSION SPRING ONCE THE SET SCREWS ARE LOOSE. Carefully adjust spring tension 1/4 turn. Retighten both set screws in the winding cone and repeat for the other side. Recheck door balance DO NOT ADJUST MORE THAN 1/2 TURN FROM THE RECOMMENDED NUMBER OF TURNS.

If door still does not balance correctly, contact a qualified door agency. If the door still does not operate easily, lower the door into the closed position, UNWIND THE SPRING(S) FULLY (Reference the insert “Removing The Old Door/Preparing The Opening” section on torsion spring removal), and recheck the following the items:

1.) Check the door for level.

2.) Check the torsion shaft for level.

3.) Check the track spacing.

4.) Check the counterbalance lift cables for equal tension.

5.) Check the track for potential obstruction of the track rollers.

15

Please Do Not Return This Product To The Store. Contact your local

refer to your local yellow pages business listings or go to the Find a Dealer section online at