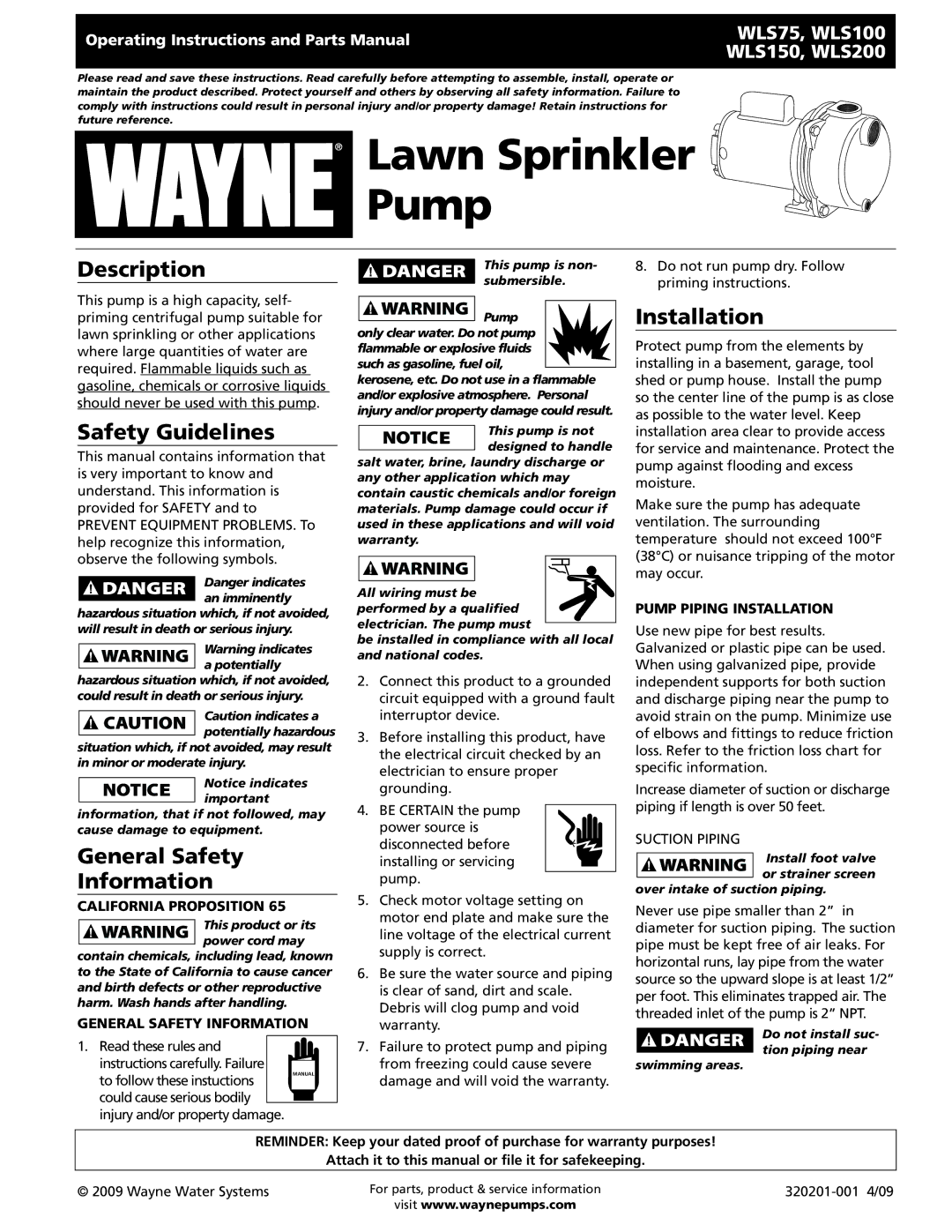

WLS150, WLS100, WLS200, WLS75 specifications

Wayne WLS75, WLS200, WLS100, and WLS150 are advanced fuel dispensers designed for efficiency and reliability in fuel retail operations. Each model has unique features that cater to various business needs while sharing core technological advancements that enhance performance.The Wayne WLS75 is a compact dispenser tailored for small to medium-sized fuel stations. It features a sleek design, user-friendly interface, and is equipped with Wayne’s patented control system that provides real-time monitoring of fuel flow and inventory levels. The WLS75 offers flexible payment options, including EMV compatibility, ensuring secure transactions. Its high-performance pump ensures quick refueling, while built-in diagnostics simplify maintenance and reduce downtime.

Moving to the WLS100, this model is designed for high-volume fuel stations. It boasts a larger capacity and increased flow rates, making it suitable for busy environments. The WLS100 incorporates advanced connectivity features, linking to cloud-based management systems for remote monitoring and analytics. This feature empowers operators to optimize fuel pricing strategies and manage inventory more effectively. Additionally, the WLS100 utilizes energy-efficient technology, minimizing operational costs while enhancing performance.

The WLS150 further ramps up the capacity and technology integration. Designed for larger retail spaces, it provides multiple fueling options, including diesel and gasoline. Its user-friendly touchscreen allows for customized branding and advertising directly on the dispenser, enhancing customer engagement. The WLS150 incorporates Wayne’s innovative fuel management software, which tracks sales and identifies trends to inform business decisions.

Lastly, the WLS200 features cutting-edge technology aimed at maximizing operational efficiency. With its robust construction, it is built to endure harsh weather conditions, ensuring reliable performance year-round. The advanced filtration system within the WLS200 minimizes contaminants, preserving fuel quality while extending the lifespan of pumps and fittings. This model also includes multiple fueling hoses, allowing simultaneous dispensing, ultimately reducing wait times for customers.

In conclusion, the Wayne WLS series—WLS75, WLS100, WLS150, and WLS200—represents a commitment to innovation in fuel dispensing technology. Each model is designed to meet the diverse needs of fuel retailers, emphasizing efficiency, reliability, and user-friendliness. With integrated technologies and features that enhance operational management and customer interaction, Wayne continues to drive progress in the fuel retail sector.