TROUBLESHOOTING AND MAINTENANCE

Make sure all parts are properly tightened each time the weight system is used. Replace any worn parts immedi- ately. The weight system can be cleaned using a damp cloth and mild

TIGHTENING THE CABLES

Woven cable, the type of cable used on the weight system, can stretch slightly when it is first used. If there is slack in the cables before resistance is felt, the cables should be tightened. Slack can be removed from the cables in several different ways.

When you are tightening the cables, note that they are linked into two distinct groups. The Rear Cable (70), the Low Cable (71), the Butterfly Cable (73), and the Ab Cable (74) are all connected to the small weight stack. All three cables will be tightened by tightening the Rear Cable at the small weight stack, or by adjusting the 90mm Pulleys (35) in either set of Pulley Plates (32).

The Press Cable (72) is attached to the large weight stack. The Press Cable can be tightened at the large weight stack or by moving the

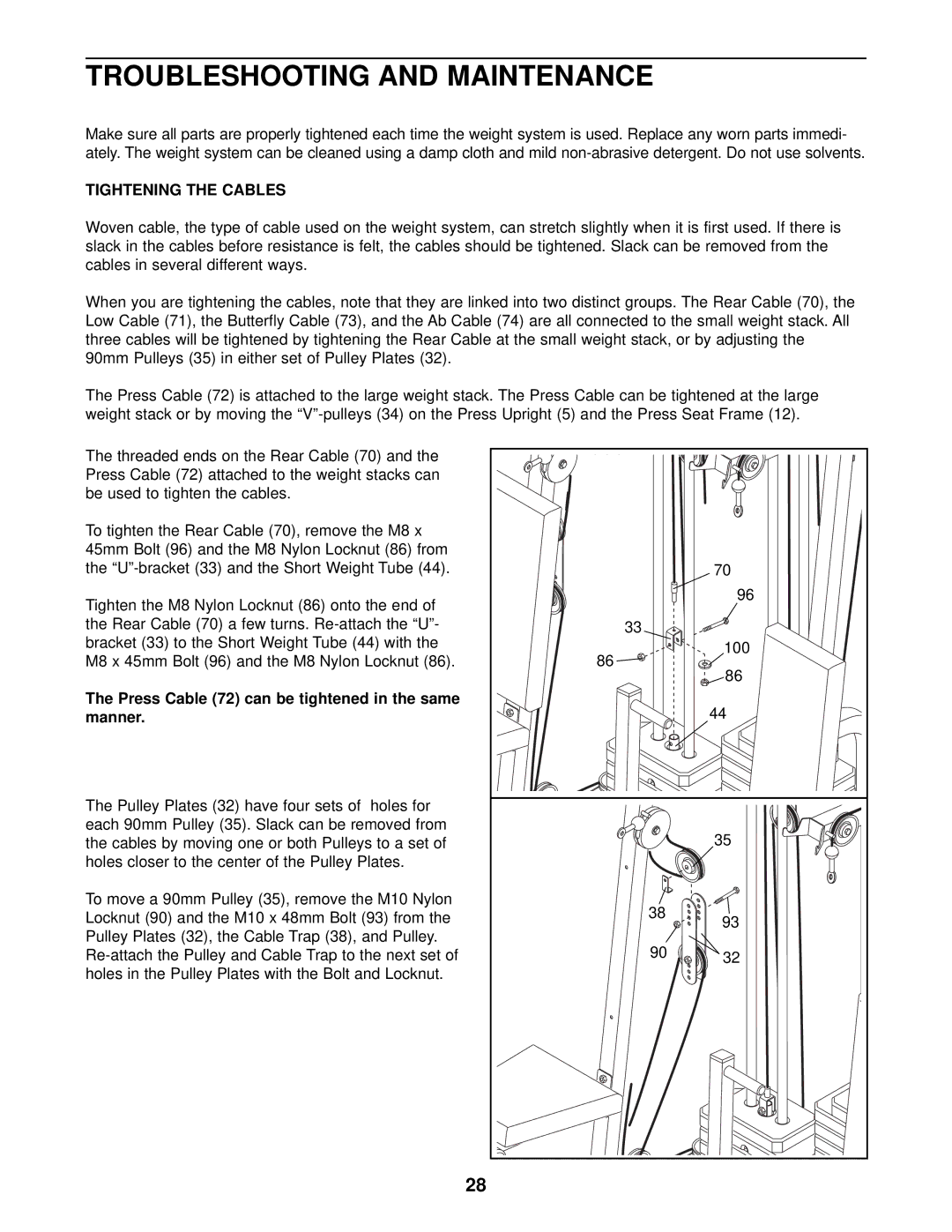

The threaded ends on the Rear Cable (70) and the Press Cable (72) attached to the weight stacks can be used to tighten the cables.

To tighten the Rear Cable (70), remove the M8 x 45mm Bolt (96) and the M8 Nylon Locknut (86) from the

Tighten the M8 Nylon Locknut (86) onto the end of the Rear Cable (70) a few turns.

The Press Cable (72) can be tightened in the same manner.

The Pulley Plates (32) have four sets of holes for each 90mm Pulley (35). Slack can be removed from the cables by moving one or both Pulleys to a set of holes closer to the center of the Pulley Plates.

To move a 90mm Pulley (35), remove the M10 Nylon Locknut (90) and the M10 x 48mm Bolt (93) from the Pulley Plates (32), the Cable Trap (38), and Pulley.

| 70 | |

| 96 | |

33 |

| |

86 | 100 | |

86 | ||

| ||

| 44 | |

| 35 | |

38 | 93 | |

| ||

90 | 32 | |

| ||

28 |

|