Lubrication

Since all bearings are sealed and permanently lubricated, leave them alone until they need to be replaced. Do not lubricate them.

The Model W1683 does need lubrication in other places.

•Columns and Lead Screws — Remove dust covers for access. Lubricate columns weekly with light oil, and lubricate the four lead screws once a month with general purpose grease.

•Worm Gear — Inspect the worm gear monthly and lubricate when needed. The worm gear box will need to be removed to perform the inspection. See Figure 37.

•Chain — Inspect the table height adjustment chain monthly and lubricate as needed. Use high quality chain lubricant for best results.

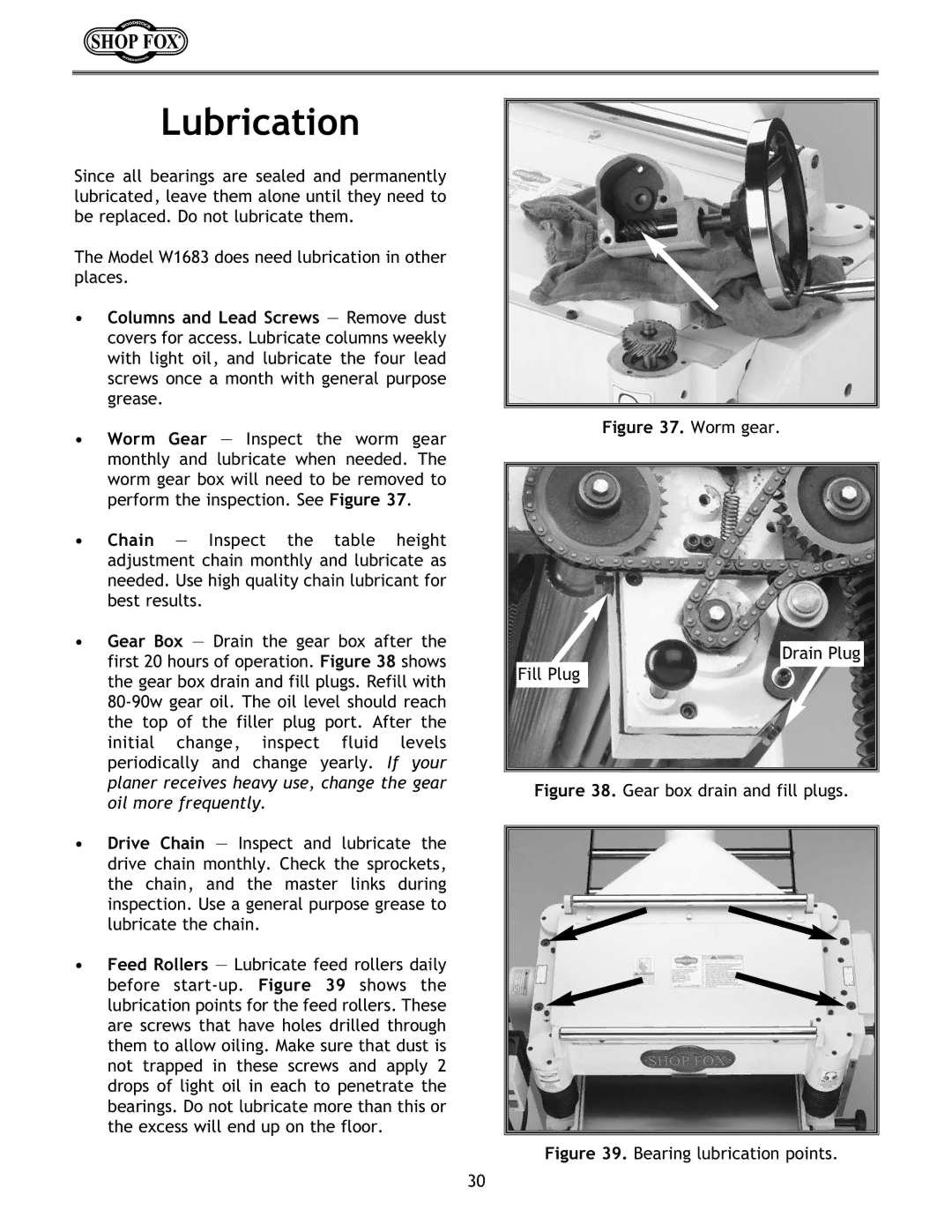

•Gear Box — Drain the gear box after the first 20 hours of operation. Figure 38 shows the gear box drain and fill plugs. Refill with

•Drive Chain — Inspect and lubricate the drive chain monthly. Check the sprockets, the chain, and the master links during inspection. Use a general purpose grease to lubricate the chain.

•Feed Rollers — Lubricate feed rollers daily before

Figure 37. Worm gear.

Drain Plug

Fill Plug

Figure 38. Gear box drain and fill plugs.

Figure 39. Bearing lubrication points.

30