Table Rollers

The table rollers should be set last so they stay out of the way during the other adjustments. The required height of the table rollers will vary depending on the type of stock you intend to plane.

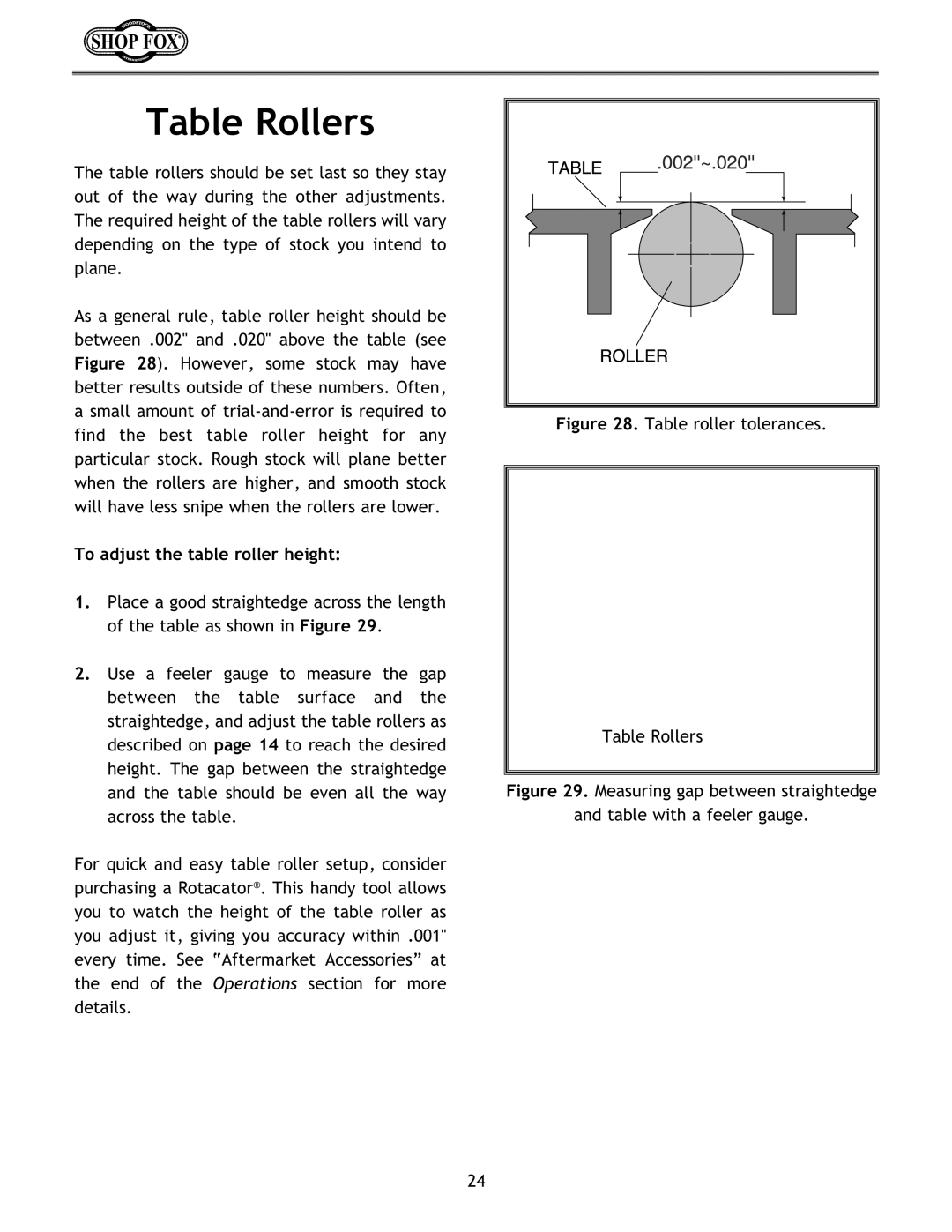

As a general rule, table roller height should be between .002" and .020" above the table (see Figure 28). However, some stock may have better results outside of these numbers. Often, a small amount of

To adjust the table roller height:

1.Place a good straightedge across the length of the table as shown in Figure 29.

2.Use a feeler gauge to measure the gap between the table surface and the straightedge, and adjust the table rollers as described on page 14 to reach the desired height. The gap between the straightedge and the table should be even all the way across the table.

For quick and easy table roller setup, consider purchasing a Rotacator®. This handy tool allows you to watch the height of the table roller as you adjust it, giving you accuracy within .001" every time. See “Aftermarket Accessories” at the end of the Operations section for more details.

Figure 28. Table roller tolerances.

Table Rollers

Figure 29. Measuring gap between straightedge

and table with a feeler gauge.

24