W1701 1HP Shaper

5.Now place a straightedge against both faces of the fence to check alignment. Once they are both in alignment, make sure the lock handle is tightened.

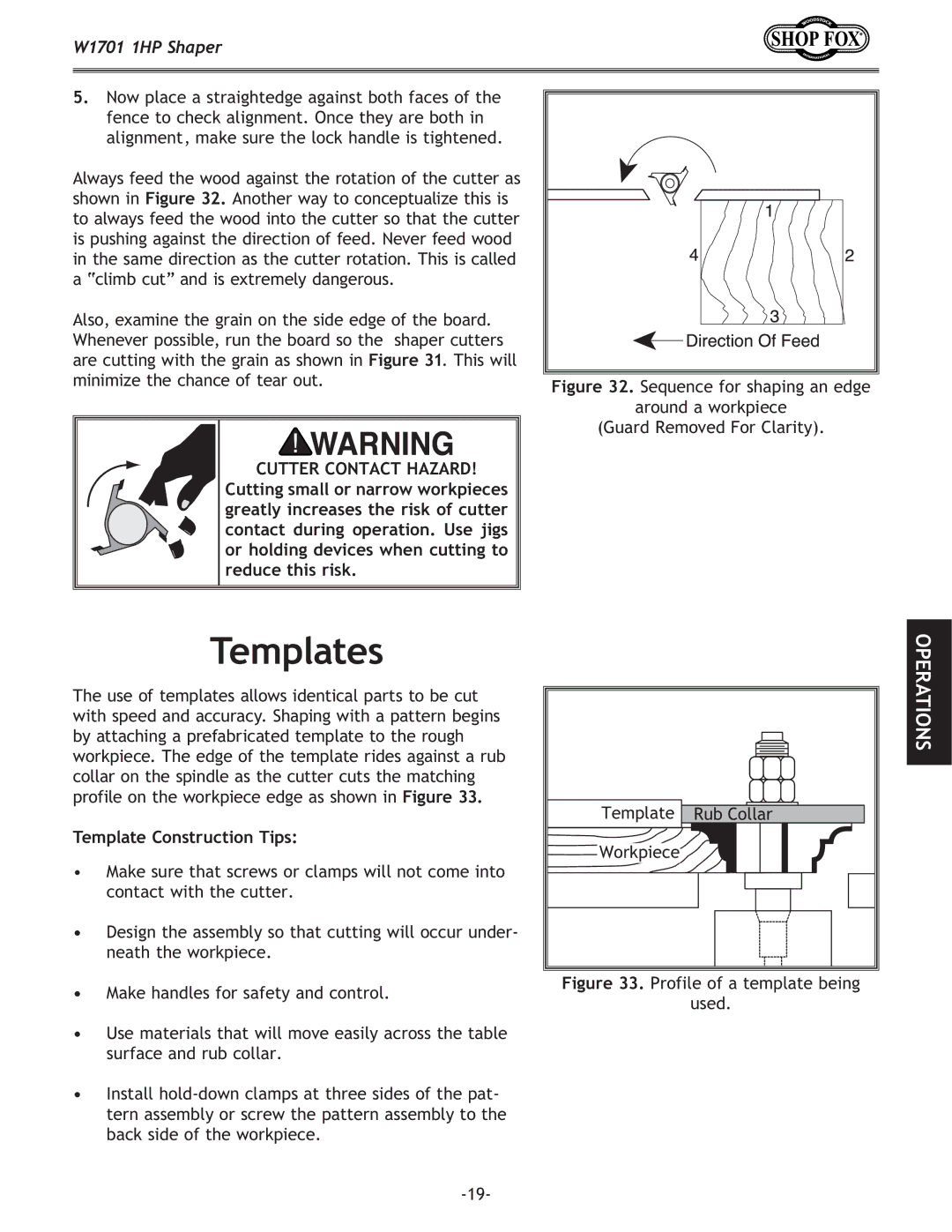

Always feed the wood against the rotation of the cutter as shown in Figure 32. Another way to conceptualize this is to always feed the wood into the cutter so that the cutter is pushing against the direction of feed. Never feed wood in the same direction as the cutter rotation. This is called a “climb cut” and is extremely dangerous.

Also, examine the grain on the side edge of the board. Whenever possible, run the board so the shaper cutters are cutting with the grain as shown in Figure 31. This will minimize the chance of tear out.

CUTTER CONTACT HAZARD!

Cutting small or narrow workpieces greatly increases the risk of cutter contact during operation. Use jigs or holding devices when cutting to reduce this risk.

Figure 32. Sequence for shaping an edge

around a workpiece

(Guard Removed For Clarity).

Templates

The use of templates allows identical parts to be cut with speed and accuracy. Shaping with a pattern begins by attaching a prefabricated template to the rough workpiece. The edge of the template rides against a rub collar on the spindle as the cutter cuts the matching profile on the workpiece edge as shown in Figure 33.

Template Construction Tips:

•Make sure that screws or clamps will not come into contact with the cutter.

•Design the assembly so that cutting will occur under- neath the workpiece.

•Make handles for safety and control.

•Use materials that will move easily across the table surface and rub collar.

•Install

�������� ����������

��������� ![]()

Figure 33. Profile of a template being

used.

OPERATIONS