W1701 1HP Shaper

SERVICE

Spindle Cartridge

Replacement

Should a bearing fail, your shaper will probably develop a noticeable rumble, which will increase when the machine is put under load. If allowed to get worse, overheating of the journal containing the bad bearing could occur, which may cause the bearing to seize and possibly damage other parts of the machine.

Rather than disassemble the spindle cartridge to remove worn out bearings, Woodstock International offers replacement spindle cartridge assemblies (Part# X1701407) as whole units, which makes replacement very simple. The procedure takes

To replace the spindle cartridge assembly:

1.DISCONNECT SHAPER FROM POWER SOURCE!

2.Remove the spindle and drawbar from the spindle cartridge assembly. (Remove tapered drawbar nut and tap the drawbar up to knock it loose.)

3.Take off the spindle pulley cover by removing the two mounting bolts shown in Figure 40.

4.Loosen the two motor mount bolts, slide the motor forward, and remove the

5.Loosen the spindle lock knob.

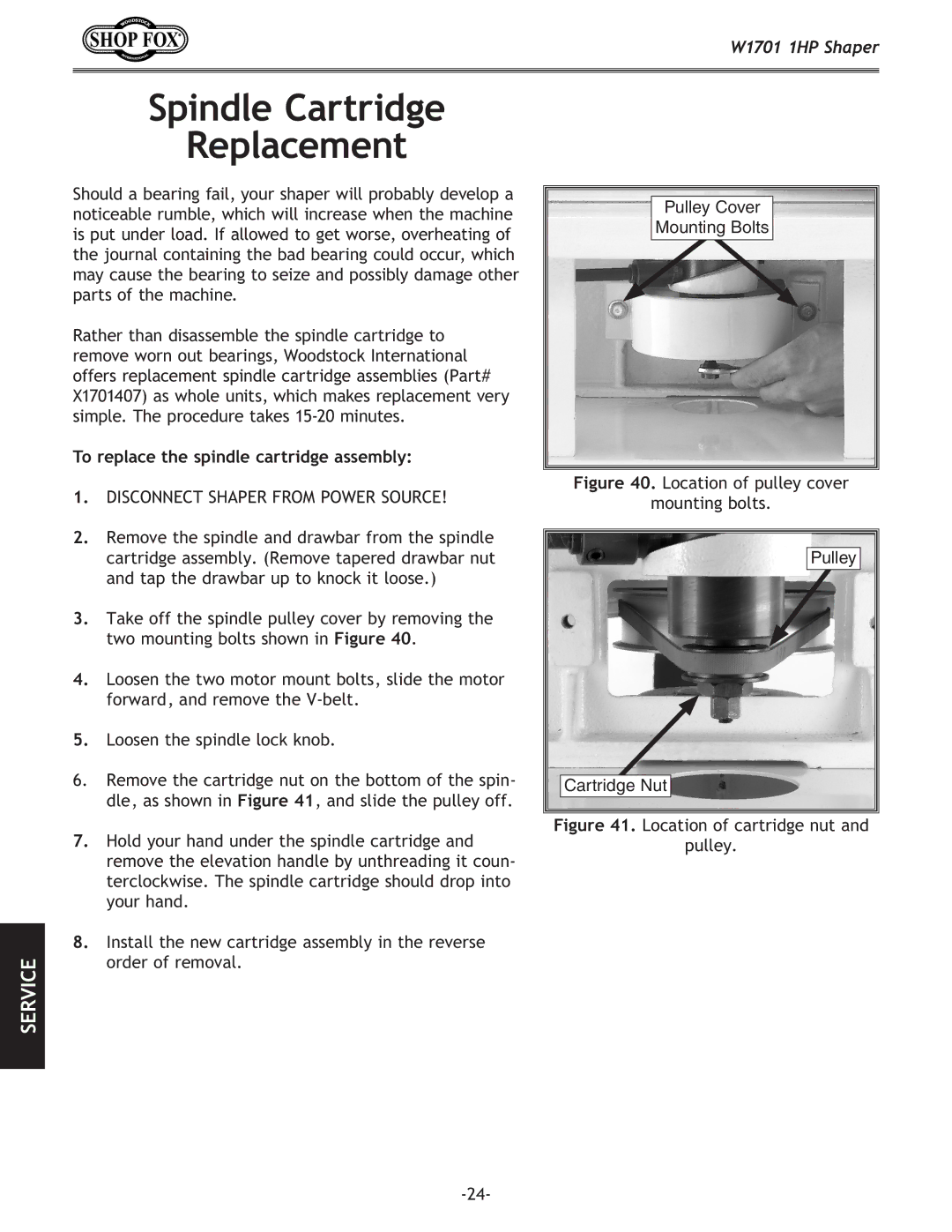

6.Remove the cartridge nut on the bottom of the spin- dle, as shown in Figure 41, and slide the pulley off.

7.Hold your hand under the spindle cartridge and remove the elevation handle by unthreading it coun- terclockwise. The spindle cartridge should drop into your hand.

8.Install the new cartridge assembly in the reverse order of removal.

Pulley Cover

Mounting Bolts

Figure 40. Location of pulley cover

mounting bolts.

Pulley

Cartridge Nut