W1730 Oscillating Edge Sander

Troubleshooting

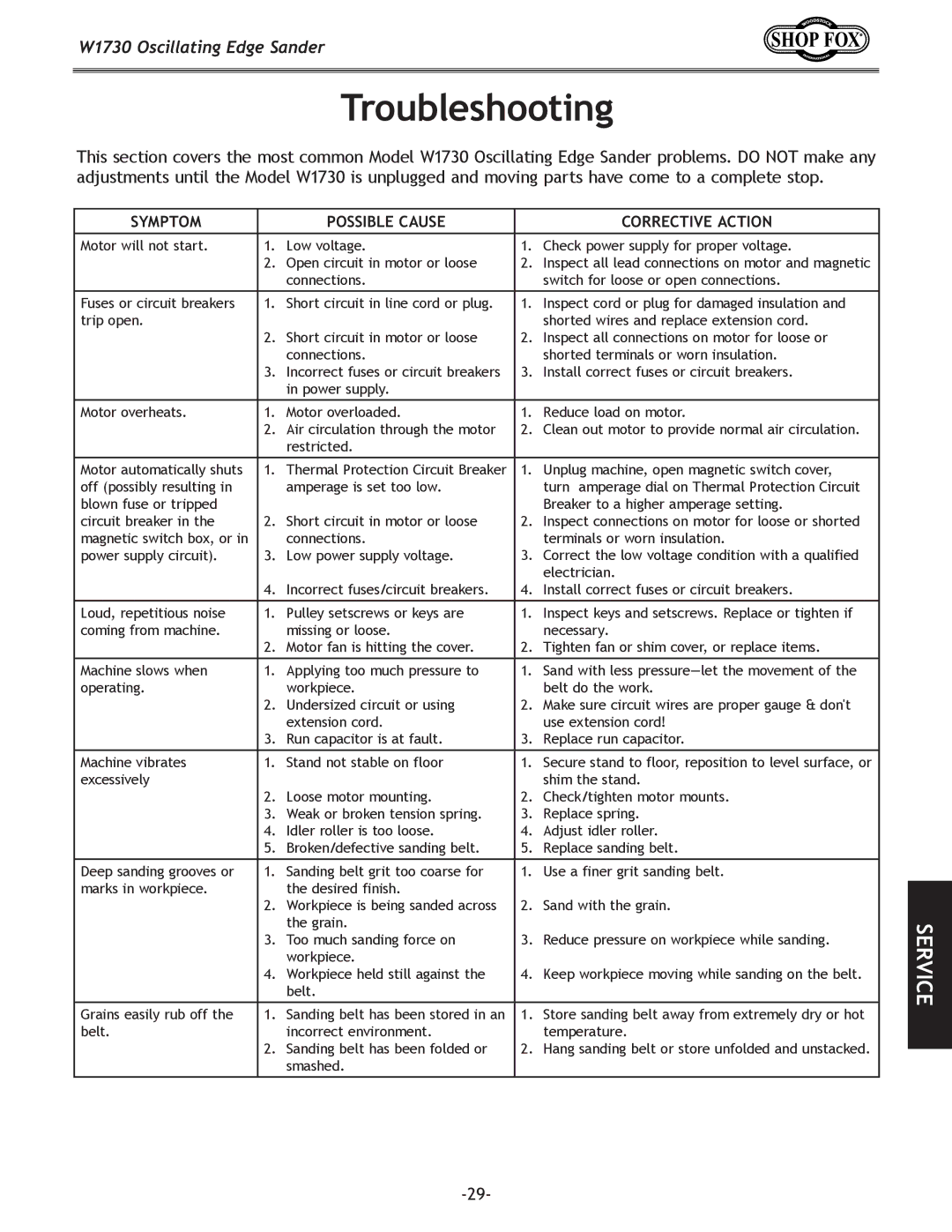

This section covers the most common Model W1730 Oscillating Edge Sander problems. DO NOT make any adjustments until the Model W1730 is unplugged and moving parts have come to a complete stop.

SYMPTOM |

| POSSIBLE CAUSE |

| corrective action |

|

|

Motor will not start. | 1. | Low voltage. | 1. | Check power supply for proper voltage. |

|

|

| 2. | Open circuit in motor or loose | 2. | Inspect all lead connections on motor and magnetic |

|

|

|

| connections. |

| switch for loose or open connections. |

|

|

|

|

|

|

|

|

|

Fuses or circuit breakers | 1. | Short circuit in line cord or plug. | 1. | Inspect cord or plug for damaged insulation and |

|

|

trip open. |

|

|

| shorted wires and replace extension cord. |

|

|

| 2. | Short circuit in motor or loose | 2. | Inspect all connections on motor for loose or |

|

|

|

| connections. |

| shorted terminals or worn insulation. |

|

|

| 3. | Incorrect fuses or circuit breakers | 3. | Install correct fuses or circuit breakers. |

|

|

|

| in power supply. |

|

|

|

|

Motor overheats. | 1. | Motor overloaded. | 1. | Reduce load on motor. |

|

|

| 2. | Air circulation through the motor | 2. | Clean out motor to provide normal air circulation. |

|

|

|

| restricted. |

|

|

|

|

|

|

|

|

|

|

|

Motor automatically shuts | 1. | Thermal Protection Circuit Breaker | 1. | Unplug machine, open magnetic switch cover, |

|

|

off (possibly resulting in |

| amperage is set too low. |

| turn amperage dial on Thermal Protection Circuit |

|

|

blown fuse or tripped |

|

|

| Breaker to a higher amperage setting. |

|

|

circuit breaker in the | 2. | Short circuit in motor or loose | 2. | Inspect connections on motor for loose or shorted |

|

|

magnetic switch box, or in |

| connections. |

| terminals or worn insulation. |

|

|

power supply circuit). | 3. | Low power supply voltage. | 3. | Correct the low voltage condition with a qualified |

|

|

|

|

|

| electrician. |

|

|

| 4. | Incorrect fuses/circuit breakers. | 4. | Install correct fuses or circuit breakers. |

|

|

Loud, repetitious noise | 1. | Pulley setscrews or keys are | 1. | Inspect keys and setscrews. Replace or tighten if |

|

|

coming from machine. |

| missing or loose. |

| necessary. |

|

|

| 2. | Motor fan is hitting the cover. | 2. | Tighten fan or shim cover, or replace items. |

|

|

|

|

|

|

|

|

|

Machine slows when | 1. | Applying too much pressure to | 1. | Sand with less |

|

|

operating. |

| workpiece. |

| belt do the work. |

|

|

| 2. | Undersized circuit or using | 2. | Make sure circuit wires are proper gauge & don't |

|

|

|

| extension cord. |

| use extension cord! |

|

|

| 3. | Run capacitor is at fault. | 3. | Replace run capacitor. |

|

|

Machine vibrates | 1. | Stand not stable on floor | 1. | Secure stand to floor, reposition to level surface, or |

|

|

excessively |

|

|

| shim the stand. |

|

|

| 2. | Loose motor mounting. | 2. | Check/tighten motor mounts. |

|

|

| 3. | Weak or broken tension spring. | 3. | Replace spring. |

|

|

| 4. | Idler roller is too loose. | 4. | Adjust idler roller. |

|

|

| 5. | Broken/defective sanding belt. | 5. | Replace sanding belt. |

|

|

|

|

|

|

|

|

|

Deep sanding grooves or | 1. | Sanding belt grit too coarse for | 1. | Use a finer grit sanding belt. |

|

|

marks in workpiece. |

| the desired finish. | 2. | Sand with the grain. |

|

|

| 2. | Workpiece is being sanded across |

|

| ||

|

| the grain. |

|

|

| SERVICE |

| 3. | Too much sanding force on | 3. | Reduce pressure on workpiece while sanding. |

| |

|

|

| ||||

|

| workpiece. |

|

|

|

|

| 4. | Workpiece held still against the | 4. | Keep workpiece moving while sanding on the belt. |

|

|

|

| belt. |

|

|

|

|

Grains easily rub off the | 1. | Sanding belt has been stored in an | 1. | Store sanding belt away from extremely dry or hot |

|

|

belt. |

| incorrect environment. |

| temperature. |

|

|

| 2. | Sanding belt has been folded or | 2. | Hang sanding belt or store unfolded and unstacked. |

|

|

|

| |||||

|

| smashed. |

|

|

|

|