OWNERS MANUAL

Page

Contents

Functional Overview

Woodstock Technical Support

Machine Specifications

W1770 21 Bandsaw w/Foot Brake

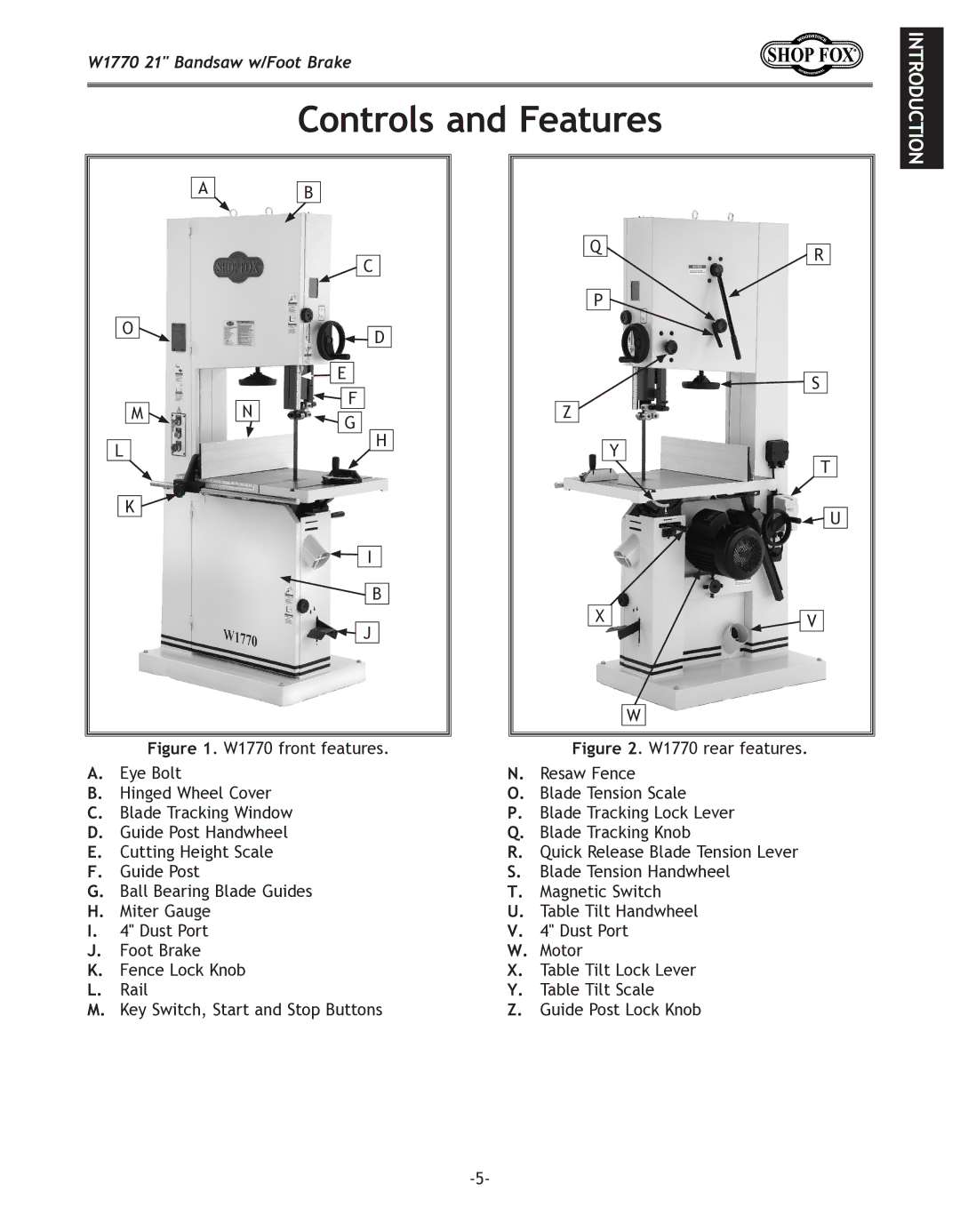

Controls and Features

Safety Safety

Always Lock Mobile Bases if Used Before Operating Machinery

Additional Safety for Bandsaws

Use push sticks whenever possible

Use push blocks when necessary

220V Operation

Electrical Specifications

Extension Cords

Unpacking

Items Needed for Setup

Description Qty

Box Inventory Figure Qty

Inventory

Hardware and Tools

Cleaning Machine

Machine Placement

Lifting the bandsaw 2x4

Lifting & Moving

Bolting to Concrete Floors

Mounting to Shop Floor

Fence

To install the fence, do these steps

Guide Post Handwheel

To center track the blade, do these steps

Blade Tracking

Changes in the blade tension may change the blade tracking

To set the positive stop, do these steps

Positive Stop

To connect the dust collection hoses, do these steps

Dust Collection

To test run the machine, do these steps

Test Run

Resetting the switch

Tensioning Blade

Adjusting Blade Guide Bearings on

To tension the bandsaw blade, do these steps

To adjust the upper blade guides, do these steps

Adjusting Blade Guide Bearings

To adjust the upper support bearing, do these steps

Adjusting Support Bearings

Blade aligned 0.016 away from Bearing edge

Lower support bearing controls

To adjust the lower support bearing, do these steps

Cap screws securing table to Trunnion

Aligning Table

Cap screws securing rail to

Aligning Fence

To calibrate the miter gauge, do these steps

Calibrating Fence Pointer

Calibrating Miter Gauge

To calibrate the pointer, do these steps

Enough to slide on the resaw fence

To install the resaw fence, do these steps

Basic Controls

General

Control Panel

Rear Controls Figure

Front Controls Figure

Cutting wood with minor Warping

Workpiece Inspection

Basic Cutting Tips

Cutting Overview

Bandsaw is capable of performing the following cuts

Guide Post

Foot Brake

Aligning Table on Page 27 and Aligning Fence on

Fine Tune Tracking

Blade Lead

Correcting Blade Lead

To shift the table, do these steps

To make a rip cut, do these steps

Table Tilt

Rip Cutting

To tilt the table, do these steps

To resaw a workpiece, do these steps

Crosscutting

Resawing

To make a 90˚ crosscut, do these steps

Stacked Cuts

Cutting Curves

To complete a stacked cut, do these steps

Blade Width

Blade Length

Tooth Style

Most common causes of blade breakage are

Tooth Pitch

Blade Care

Blade Breakage

To remove a blade, do these steps

Blade Changes

To replace a blade, do these steps

Lubrication

Cleaning

Table & Base

Brushes

Blade Guide Rack and Pinion

Tension Adjustment Assembly

Lubricant Frequency Quantity

Trunnion

Table Tilt Rack and Pinion Assembly

To lubricate the trunnion, do these steps

Checking V-Belts

Checking and Tensioning Belts

Tools Needed

Replacing V-Belts

Tensioning V-Belts

Follow Steps 1-2 in Checking V-Belts on

To adjust the tension lever, do these steps

Adjusting Tension Lever

To adjust the brushes, do these steps

Adjusting Wheel Blade Brushes

Follow Steps 1-4 in Replacing V-Belts on

Replacing Brake Shoe

Components and Hardware Needed

To replace the brake shoe

Checking Coplanarity

Aligning Wheels

Gauge

Shimming Upper Wheel

To adjust the lower wheel, do these steps

Adjusting Lower Wheel

Electrical Components

Power supply terminal box

See ,

Wiring Diagram

See Figure

Motor & Electrical

Troubleshooting

Cutting Tips on

Machine Operations

Labels & Cosmetic Parts

Parts

Blade Guides-Cover Breakdown

Parts

Guide Post-Table Tilt Breakdown

Table-Trunnion Breakdown

Body Breakdown

Capacitor Cover

Body Parts List

Motor Cord 12AWG X 3C

Resaw Fence Breakdown

Comments

Warranty Registration

Woodstock international inc. p.o. box Bellingham, wa

Warranty

![]()

![]()

![]()

![]() C

C![]()

![]() D

D![]()

![]() E

E![]()

![]() F

F![]() G

G![]()

![]() H

H![]()

![]() I

I![]() B

B![]()

![]() J

J