H. Using Stop Blocks

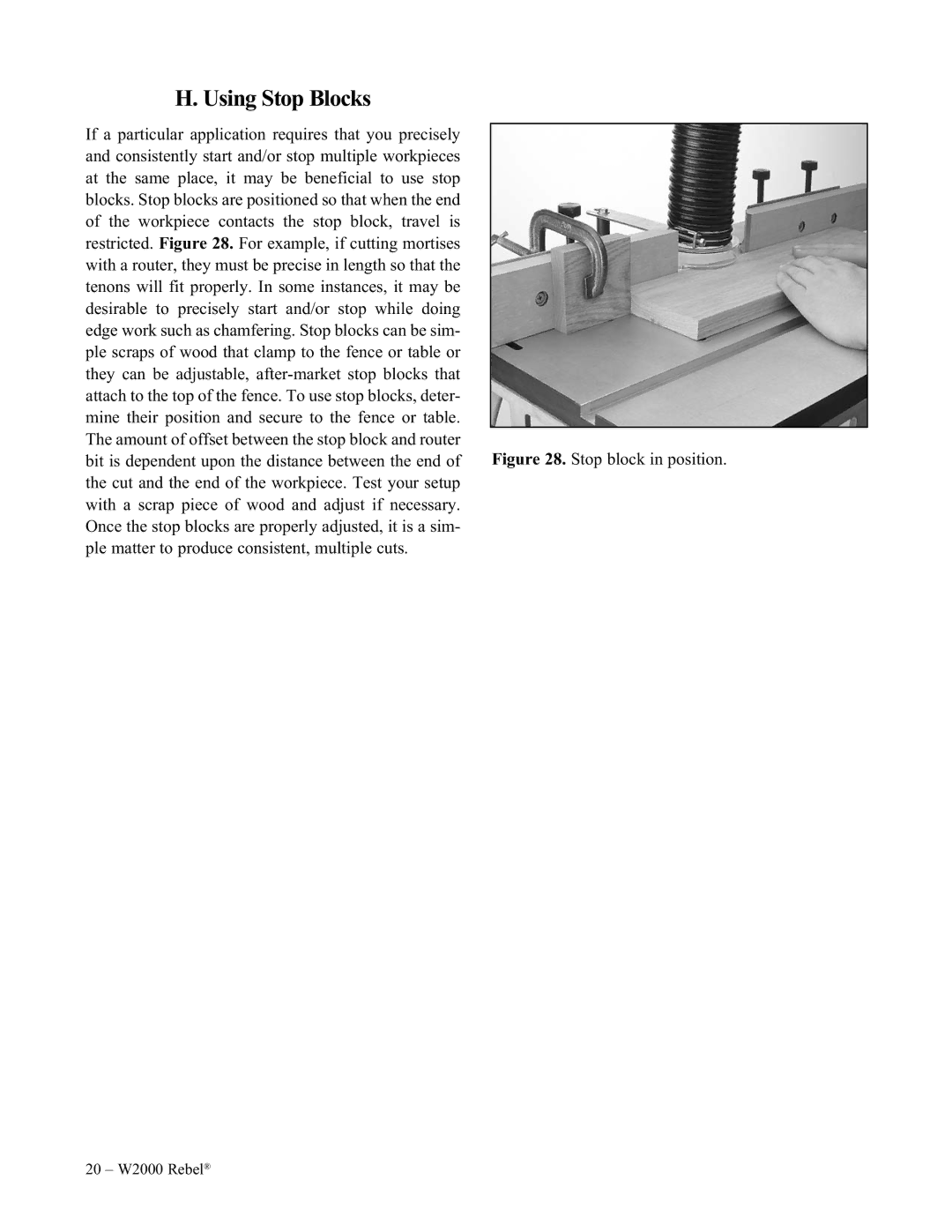

If a particular application requires that you precisely and consistently start and/or stop multiple workpieces at the same place, it may be beneficial to use stop blocks. Stop blocks are positioned so that when the end of the workpiece contacts the stop block, travel is restricted. Figure 28. For example, if cutting mortises with a router, they must be precise in length so that the tenons will fit properly. In some instances, it may be desirable to precisely start and/or stop while doing edge work such as chamfering. Stop blocks can be sim- ple scraps of wood that clamp to the fence or table or they can be adjustable,

bit is dependent upon the distance between the end of Figure 28. Stop block in position. the cut and the end of the workpiece. Test your setup

with a scrap piece of wood and adjust if necessary. Once the stop blocks are properly adjusted, it is a sim- ple matter to produce consistent, multiple cuts.

20 – W2000 Rebel®