of the UCB. If 24 volts is present, trace the wiring from Y1 “OUT” for incorrect wiring. If 24 volts is not present at the Y1 “OUT” terminal, the UCB must be replaced.

12.For units without economizers: If 24 volts is present at the Y1 OUT terminal, check for 24 volts at the Y1 “ECON” terminal. If 24 volts is not present, check for loose wiring from the Y1 “OUT” terminal to the

13.For units with economizers: If 24 volts is present at the Y1 “OUT” terminal, check for 24 volts at the Y1 “ECON” terminal. If 24 volts is not present, check for loose wiring from the Y1 “OUT” terminal to the

14.The UCB can be programmed to lock out compres- sor operation during free cooling and in low ambi- ent conditions. These options are not enabled by default. Local distributors can test the UCB for this programming.

For units with factory installed economizers, the UCB is programmed to lock out compressor opera- tion when the LAS set point is reached.

For units without factory installed or with field installed economizers, the UCB allows compressor operation all the time. This programming can be checked or changed by the local distributor.

15.If none of the above correct the error, replace the UCB.

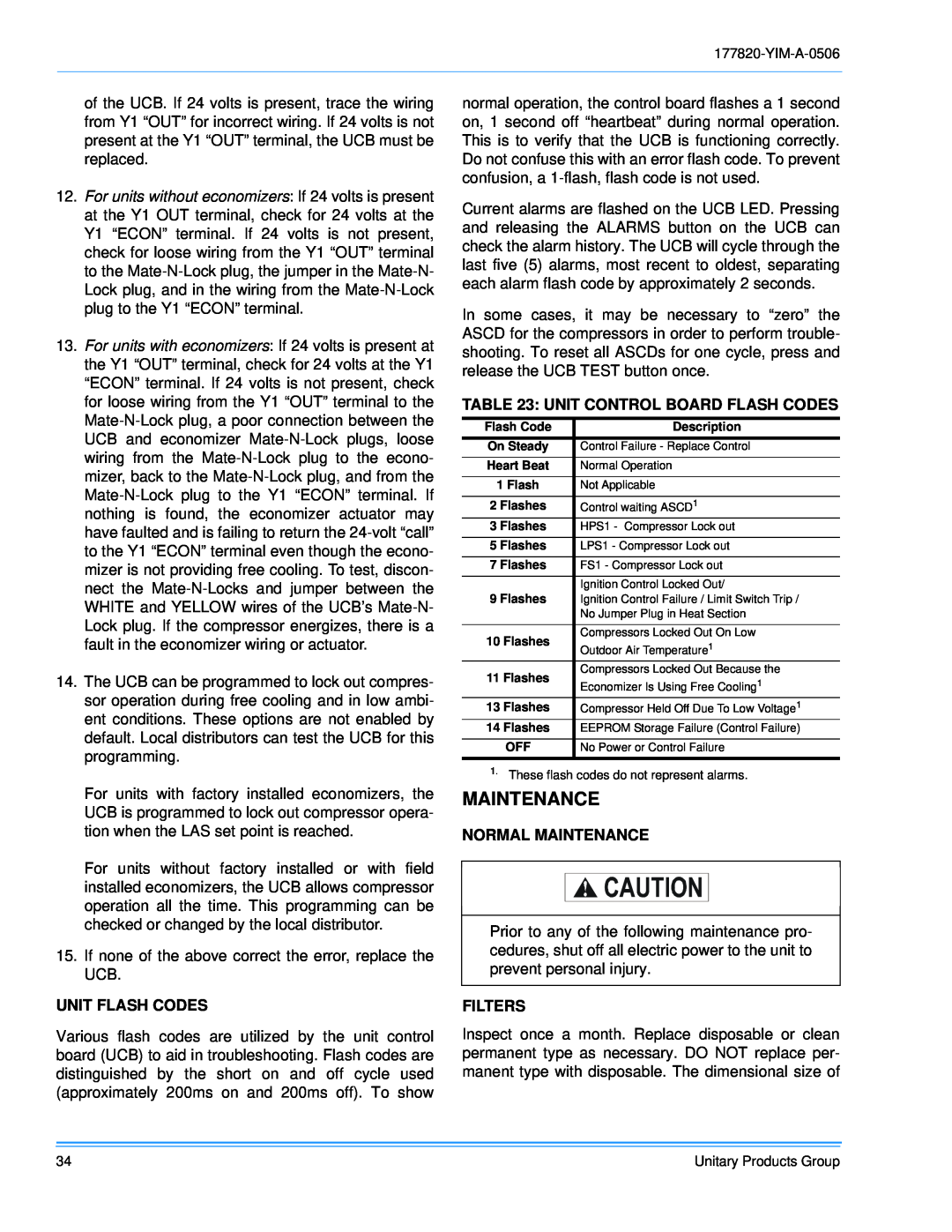

UNIT FLASH CODES

Various flash codes are utilized by the unit control board (UCB) to aid in troubleshooting. Flash codes are distinguished by the short on and off cycle used (approximately 200ms on and 200ms off). To show

normal operation, the control board flashes a 1 second on, 1 second off “heartbeat” during normal operation. This is to verify that the UCB is functioning correctly. Do not confuse this with an error flash code. To prevent confusion, a

Current alarms are flashed on the UCB LED. Pressing and releasing the ALARMS button on the UCB can check the alarm history. The UCB will cycle through the last five (5) alarms, most recent to oldest, separating each alarm flash code by approximately 2 seconds.

In some cases, it may be necessary to “zero” the ASCD for the compressors in order to perform trouble- shooting. To reset all ASCDs for one cycle, press and release the UCB TEST button once.

TABLE 23: UNIT CONTROL BOARD FLASH CODES

Flash Code | Description | |

On Steady | Control Failure - Replace Control | |

Heart Beat | Normal Operation | |

1 Flash | Not Applicable | |

2 Flashes | Control waiting ASCD1 | |

3 Flashes | HPS1 - Compressor Lock out | |

5 Flashes | LPS1 - Compressor Lock out | |

7 Flashes | FS1 - Compressor Lock out | |

9 Flashes | Ignition Control Locked Out/ | |

Ignition Control Failure / Limit Switch Trip / | ||

| No Jumper Plug in Heat Section | |

|

| |

10 Flashes | Compressors Locked Out On Low | |

Outdoor Air Temperature1 | ||

| ||

11 Flashes | Compressors Locked Out Because the | |

Economizer Is Using Free Cooling1 | ||

| ||

13 Flashes | Compressor Held Off Due To Low Voltage1 | |

14 Flashes | EEPROM Storage Failure (Control Failure) | |

OFF | No Power or Control Failure |

1.These flash codes do not represent alarms.

MAINTENANCE

NORMAL MAINTENANCE

Prior to any of the following maintenance pro- cedures, shut off all electric power to the unit to prevent personal injury.

FILTERS

Inspect once a month. Replace disposable or clean permanent type as necessary. DO NOT replace per- manent type with disposable. The dimensional size of

34 | Unitary Products Group |